Multi-Location Inventory Management: What, Why, and How?

Oct 13, 2025

Multi-location inventory management is tracking and controlling inventory across 2 or more physical sites like warehouses, stores,... via a single connected system.

The modern retail chain rarely runs from one warehouse. A single brand might fulfill online orders from a central DC, restock from regional hubs, and sell through flagship stores or marketplaces — all at once.

Each of these nodes has its own inventory realities: different stock levels, lead times, and demand spikes. Without a unified view, it’s easy to over-order in one place, under-stock in another, and lose money (and customers) in between.

Multi-location inventory management is how growing brands bring it all together. It’s the practice of monitoring, balancing, and optimizing stock across every location — in real time.

In this guide, we’ll explore what it is, why it matters, the challenges it solves, and how to implement it with modern systems (and a little help from AI).

What Is Multi-Location Inventory Management?

At its core, multi-location inventory management means tracking and controlling inventory across two or more physical sites — warehouses, stores, or fulfillment centers — through a single connected system.

Unlike a single-warehouse setup, it adds layers of complexity:

Each location can receive, hold, and dispatch stock independently.

Transfers between sites must be tracked like purchases and sales.

Data needs to sync instantly to maintain accuracy across systems.

Example: A fashion brand stores its core styles in a Singapore DC, but also keeps a small stock of fast-moving SKUs in store hubs in Sydney and Kuala Lumpur. When a customer orders online, the system fulfills from the nearest site — cutting shipping time and cost.

That’s multi-location inventory management in action: faster, smarter, and leaner.

What Is Multi-Location Inventory Management?

Why Multi-Location Inventory Management Matters?

Operational Efficiency: Synchronizes inbound purchasing, inter-warehouse transfers, and outbound fulfillment — cutting redundant work and manual data entry.

Stock Accuracy: Reduces mismatch between what’s shown online vs. what’s actually on hand, preventing canceled or delayed orders.

Cost Control: Optimizes inventory allocation to reduce overstocking and avoid emergency transfers.

Faster Fulfillment: Enables ship-from-store and regional fulfillment — customers get products sooner.

Scalability: As you open new stores or expand to new regions, the system grows with you — no more spreadsheets per location.

Data-Driven Decisions: See which products perform best in each region and allocate inventory accordingly.

Resilience: When disruptions hit (supplier delays, regional demand surges), brands can rebalance and reroute stock from one site to another — maintaining continuity and customer trust.

Key Challenges in Multi-Location Inventory

Managing multiple sites sounds great — until you’re the one reconciling the stock counts. Common challenges include:

Fragmented visibility: Data arrives late or inconsistently across warehouses and stores.

Transfer complexity: Manual transfers lead to duplication, delay, and lost shipments.

Unreliable forecasting: Each site’s unique demand complicates planning.

Disconnected systems: WMS, ERP, POS, and e-commerce tools don't talk to each other.

Carrying cost creep: Some locations overflow while others go out of stock.

Manual errors: Updating spreadsheets by hand multiplies mistakes.

Regulatory differences: Regional tax or compliance variations make reconciliation messy.

Without integration, every location becomes its own island — data silos, wasted hours, and lost sales.

How to Improve Multi-Location Inventory Management?

Centralize Data and Visibility: Adopt a single platform that consolidates stock data across all sites — real time, no manual syncs. Real-time visibility eliminates blind spots and manual reconciliations, ensuring every team operates on the same version of truth.

Automate Replenishment and Transfers: Use demand signals, lead times, and minimum thresholds to trigger restocks or move stock automatically between locations. Set dynamic reorder points per site to minimize both shortages and overstocks. Predictive algorithms can analyze order velocity to suggest proactive stock moves before an imbalance occurs.

>> Read more: 10 Best Inventory Replenishment Software Solutions

Standardize Processes and SKU Data: Ensure consistent product codes, attributes, and naming conventions. Consistent data ensures smooth reporting, accurate analytics, and easier cross-location coordination.

Implement Demand-Based Replenishment: Forecast based on regional trends, not global averages. Each region has unique seasonality and buying behavior. Machine learning/AI can improve these forecasts by factoring in weather, promotions, or local events.

>> Read more: 7 Best AI-Powered Demand Forecasting Tools for Fashion

Leverage Real-Time Tracking Technology: RFID, barcode scanning, and IoT sensors improve accuracy and traceability. Real-time updates increase accuracy, reduce shrinkage, and support live dashboards for decision-making.

Optimize Transfer and Fulfillment Routes: Automate “ship from nearest” logic to save time and shipping cost. AI-driven route optimization can also balance cost efficiency with sustainability goals.

Use Location-Specific Analytics: Measure sell-through, stock-out %, and returns by site to uncover local patterns. These insights reveal which warehouses are overstocked, which regions need faster replenishment, and where to invest in additional capacity.

Integrate Systems Across Functions: Connect WMS, ERP, POS, and e-commerce for continuous data flow. Integration ensures all departments act on consistent, up-to-date information.

Enhance Collaboration Between Teams: Create shared dashboards and automated alerts for low stock, delayed shipments, or excess capacity. When operations, merchandising, and finance work from one dataset, alignment improves naturally.

Build Flexibility and Resilience: Set safety stock buffers for high-risk SKUs and plan alternative fulfillment routes. Scenario testing tools can simulate demand surges or supply delays to help prepare response strategies.

Continuously Review and Optimize: Set quarterly audits to rebalance stock policies and performance KPIs. This keeps the system lean, responsive, and aligned with business goals.

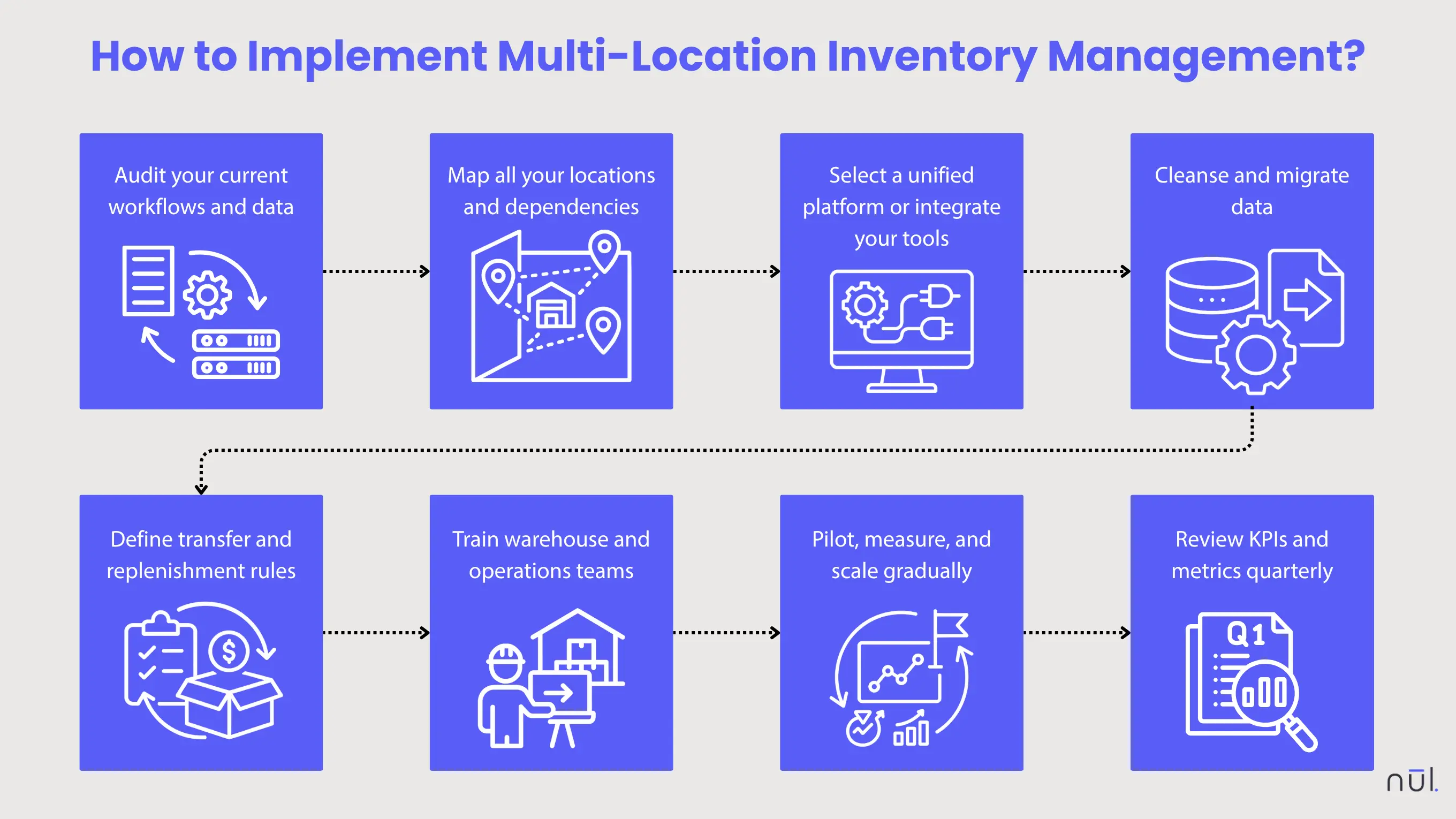

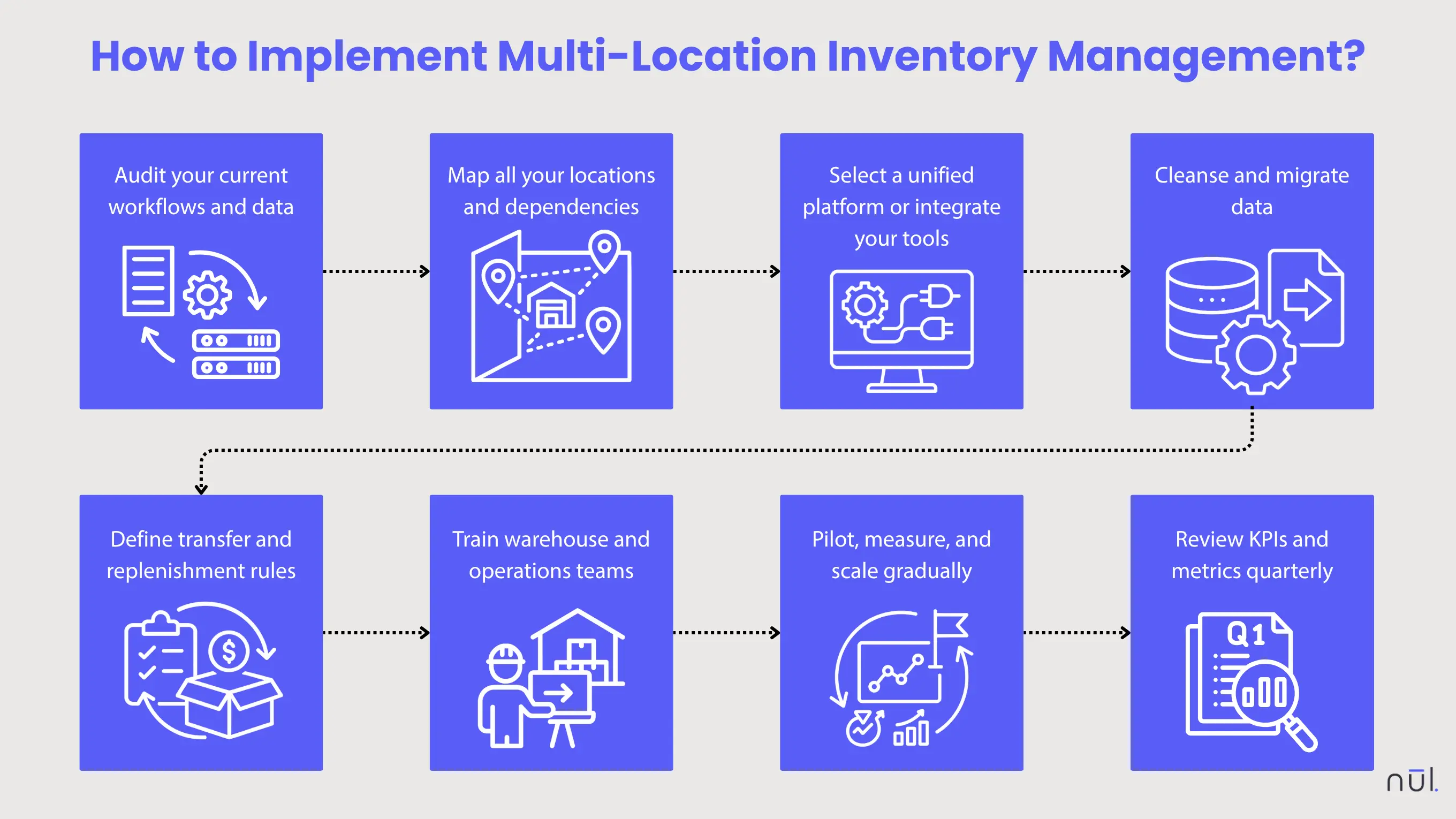

How to Implement Multi-Location Inventory Management?

Audit your current workflows and data: Identify gaps in tracking, reporting, visibility, and all your inventory processes. Identify whether it's delayed updates, manual entries, or missing data.

Map all your locations and dependencies: List every node in your supply network: warehouses, stores, suppliers, and delivery partners. Document how goods move between them and where delays or visibility gaps occur.

Select a unified platform or integrate your tools: ERP, WMS, POS — choose solutions that can sync. If a full replacement isn’t feasible, integrate what you already use through APIs or middleware.

Cleanse and migrate data: Standardize SKUs, units, and locations before rollout. Migrate only verified records to prevent duplicate or outdated entries from clogging the new system.

Define transfer and replenishment rules: Set reorder points, lead times, and buffer stock per site. Automation works best when these parameters are defined early.

Train warehouse and operations teams: Consistent practices reduce discrepancy risk. Provide training on new tools, scanning workflows, and reporting procedures.

Pilot, measure, and scale gradually: Start with a few key SKUs or regions. Monitor how well data syncs, transfers execute, and orders fulfill. Collect feedback, refine processes, then scale the system across your full network once stability is proven.

Review KPIs quarterly: Track fulfillment time, stock accuracy, and carrying cost.

Tip: Document every phase — from data mapping to team onboarding — so future expansions or location rollouts follow a clear, proven playbook.

How to Implement Multi-Location Inventory Management?

How Nūl Supports Multi-Location Inventory Management?

At Nūl, we’ve built our platform to help brands manage distributed inventory networks — without the chaos.

Network-Wide Visibility: See every warehouse, store, and channel in one dashboard.

AI-Based Transfer Optimization: Our agent learns movement patterns and suggests optimal transfers — minimizing cost and delays.

Smart Replenishment Rules: Automate reorder points per location based on real-time sales velocity.

Profit + Emission Lens: Balance financial efficiency with environmental impact — a new dimension in supply chain planning.

Seamless Integration: Nūl connects with existing ERPs, Shopify, WMS, and analytics tools — no rebuild required.

Conclusion

Multi-location inventory management isn’t just a logistics upgrade — it’s the foundation of modern retail. It’s how brands achieve speed, accuracy, and scalability across markets. When done right, it turns a fragmented supply chain into a connected ecosystem — one that’s leaner, smarter, and more sustainable.

Article by

Nūl Content Team

An Experienced Research & Knowledge Team

The Nūl Content Team combines expertise in technology, fashion, and supply chain management to deliver clear, practical insights. Guided by Nūl’s mission to end overproduction, we create content that helps brands forecast demand more accurately, optimize inventory, and build sustainable operations. Every piece we publish is grounded in real-world experience, ensuring it’s both credible and actionable.

LinkedIn Profile

More From Blog

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

More From Blog

Multi-Location Inventory Management: What, Why, and How?

Oct 13, 2025

Multi-location inventory management is tracking and controlling inventory across 2 or more physical sites like warehouses, stores,... via a single connected system.

The modern retail chain rarely runs from one warehouse. A single brand might fulfill online orders from a central DC, restock from regional hubs, and sell through flagship stores or marketplaces — all at once.

Each of these nodes has its own inventory realities: different stock levels, lead times, and demand spikes. Without a unified view, it’s easy to over-order in one place, under-stock in another, and lose money (and customers) in between.

Multi-location inventory management is how growing brands bring it all together. It’s the practice of monitoring, balancing, and optimizing stock across every location — in real time.

In this guide, we’ll explore what it is, why it matters, the challenges it solves, and how to implement it with modern systems (and a little help from AI).

What Is Multi-Location Inventory Management?

At its core, multi-location inventory management means tracking and controlling inventory across two or more physical sites — warehouses, stores, or fulfillment centers — through a single connected system.

Unlike a single-warehouse setup, it adds layers of complexity:

Each location can receive, hold, and dispatch stock independently.

Transfers between sites must be tracked like purchases and sales.

Data needs to sync instantly to maintain accuracy across systems.

Example: A fashion brand stores its core styles in a Singapore DC, but also keeps a small stock of fast-moving SKUs in store hubs in Sydney and Kuala Lumpur. When a customer orders online, the system fulfills from the nearest site — cutting shipping time and cost.

That’s multi-location inventory management in action: faster, smarter, and leaner.

What Is Multi-Location Inventory Management?

Why Multi-Location Inventory Management Matters?

Operational Efficiency: Synchronizes inbound purchasing, inter-warehouse transfers, and outbound fulfillment — cutting redundant work and manual data entry.

Stock Accuracy: Reduces mismatch between what’s shown online vs. what’s actually on hand, preventing canceled or delayed orders.

Cost Control: Optimizes inventory allocation to reduce overstocking and avoid emergency transfers.

Faster Fulfillment: Enables ship-from-store and regional fulfillment — customers get products sooner.

Scalability: As you open new stores or expand to new regions, the system grows with you — no more spreadsheets per location.

Data-Driven Decisions: See which products perform best in each region and allocate inventory accordingly.

Resilience: When disruptions hit (supplier delays, regional demand surges), brands can rebalance and reroute stock from one site to another — maintaining continuity and customer trust.

Key Challenges in Multi-Location Inventory

Managing multiple sites sounds great — until you’re the one reconciling the stock counts. Common challenges include:

Fragmented visibility: Data arrives late or inconsistently across warehouses and stores.

Transfer complexity: Manual transfers lead to duplication, delay, and lost shipments.

Unreliable forecasting: Each site’s unique demand complicates planning.

Disconnected systems: WMS, ERP, POS, and e-commerce tools don't talk to each other.

Carrying cost creep: Some locations overflow while others go out of stock.

Manual errors: Updating spreadsheets by hand multiplies mistakes.

Regulatory differences: Regional tax or compliance variations make reconciliation messy.

Without integration, every location becomes its own island — data silos, wasted hours, and lost sales.

How to Improve Multi-Location Inventory Management?

Centralize Data and Visibility: Adopt a single platform that consolidates stock data across all sites — real time, no manual syncs. Real-time visibility eliminates blind spots and manual reconciliations, ensuring every team operates on the same version of truth.

Automate Replenishment and Transfers: Use demand signals, lead times, and minimum thresholds to trigger restocks or move stock automatically between locations. Set dynamic reorder points per site to minimize both shortages and overstocks. Predictive algorithms can analyze order velocity to suggest proactive stock moves before an imbalance occurs.

>> Read more: 10 Best Inventory Replenishment Software Solutions

Standardize Processes and SKU Data: Ensure consistent product codes, attributes, and naming conventions. Consistent data ensures smooth reporting, accurate analytics, and easier cross-location coordination.

Implement Demand-Based Replenishment: Forecast based on regional trends, not global averages. Each region has unique seasonality and buying behavior. Machine learning/AI can improve these forecasts by factoring in weather, promotions, or local events.

>> Read more: 7 Best AI-Powered Demand Forecasting Tools for Fashion

Leverage Real-Time Tracking Technology: RFID, barcode scanning, and IoT sensors improve accuracy and traceability. Real-time updates increase accuracy, reduce shrinkage, and support live dashboards for decision-making.

Optimize Transfer and Fulfillment Routes: Automate “ship from nearest” logic to save time and shipping cost. AI-driven route optimization can also balance cost efficiency with sustainability goals.

Use Location-Specific Analytics: Measure sell-through, stock-out %, and returns by site to uncover local patterns. These insights reveal which warehouses are overstocked, which regions need faster replenishment, and where to invest in additional capacity.

Integrate Systems Across Functions: Connect WMS, ERP, POS, and e-commerce for continuous data flow. Integration ensures all departments act on consistent, up-to-date information.

Enhance Collaboration Between Teams: Create shared dashboards and automated alerts for low stock, delayed shipments, or excess capacity. When operations, merchandising, and finance work from one dataset, alignment improves naturally.

Build Flexibility and Resilience: Set safety stock buffers for high-risk SKUs and plan alternative fulfillment routes. Scenario testing tools can simulate demand surges or supply delays to help prepare response strategies.

Continuously Review and Optimize: Set quarterly audits to rebalance stock policies and performance KPIs. This keeps the system lean, responsive, and aligned with business goals.

How to Implement Multi-Location Inventory Management?

Audit your current workflows and data: Identify gaps in tracking, reporting, visibility, and all your inventory processes. Identify whether it's delayed updates, manual entries, or missing data.

Map all your locations and dependencies: List every node in your supply network: warehouses, stores, suppliers, and delivery partners. Document how goods move between them and where delays or visibility gaps occur.

Select a unified platform or integrate your tools: ERP, WMS, POS — choose solutions that can sync. If a full replacement isn’t feasible, integrate what you already use through APIs or middleware.

Cleanse and migrate data: Standardize SKUs, units, and locations before rollout. Migrate only verified records to prevent duplicate or outdated entries from clogging the new system.

Define transfer and replenishment rules: Set reorder points, lead times, and buffer stock per site. Automation works best when these parameters are defined early.

Train warehouse and operations teams: Consistent practices reduce discrepancy risk. Provide training on new tools, scanning workflows, and reporting procedures.

Pilot, measure, and scale gradually: Start with a few key SKUs or regions. Monitor how well data syncs, transfers execute, and orders fulfill. Collect feedback, refine processes, then scale the system across your full network once stability is proven.

Review KPIs quarterly: Track fulfillment time, stock accuracy, and carrying cost.

Tip: Document every phase — from data mapping to team onboarding — so future expansions or location rollouts follow a clear, proven playbook.

How to Implement Multi-Location Inventory Management?

How Nūl Supports Multi-Location Inventory Management?

At Nūl, we’ve built our platform to help brands manage distributed inventory networks — without the chaos.

Network-Wide Visibility: See every warehouse, store, and channel in one dashboard.

AI-Based Transfer Optimization: Our agent learns movement patterns and suggests optimal transfers — minimizing cost and delays.

Smart Replenishment Rules: Automate reorder points per location based on real-time sales velocity.

Profit + Emission Lens: Balance financial efficiency with environmental impact — a new dimension in supply chain planning.

Seamless Integration: Nūl connects with existing ERPs, Shopify, WMS, and analytics tools — no rebuild required.

Conclusion

Multi-location inventory management isn’t just a logistics upgrade — it’s the foundation of modern retail. It’s how brands achieve speed, accuracy, and scalability across markets. When done right, it turns a fragmented supply chain into a connected ecosystem — one that’s leaner, smarter, and more sustainable.

Article by

Nūl Content Team

An Experienced Research & Knowledge Team

An Experienced Research & Knowledge Team

The Nūl Content Team combines expertise in technology, fashion, and supply chain management to deliver clear, practical insights. Guided by Nūl’s mission to end overproduction, we create content that helps brands forecast demand more accurately, optimize inventory, and build sustainable operations. Every piece we publish is grounded in real-world experience, ensuring it’s both credible and actionable.

LinkedIn Profile