How to Automate Purchase Orders? Benefits & Best Practices

Oct 20, 2025

Purchase order automation uses digital systems often powered by AI to automatically generate, route, and approve purchase orders based on set rules or data inputs.

For many fashion and retail businesses, purchase orders (POs) are the lifeblood of production and inventory management. Yet, managing them manually often leads to delays, data entry errors, and compliance headaches.

When every order requires manual review, email threads pile up, spreadsheets get outdated, and approvals stall. The result? Lost time, miscommunication with suppliers, and stock imbalances that impact both profits and sustainability goals.

That’s where purchase order automation steps in — a smarter way to handle procurement. In this guide, we’ll break down what it means, the benefits, and how to implement it effectively — with insights from how modern AI-driven tools streamline the process.

What is Purchase Order Automation?

Purchase order automation uses digital systems — often powered by AI — to automatically generate, route, and approve purchase orders based on predefined rules or data inputs.

Traditional PO | Automated PO |

|---|---|

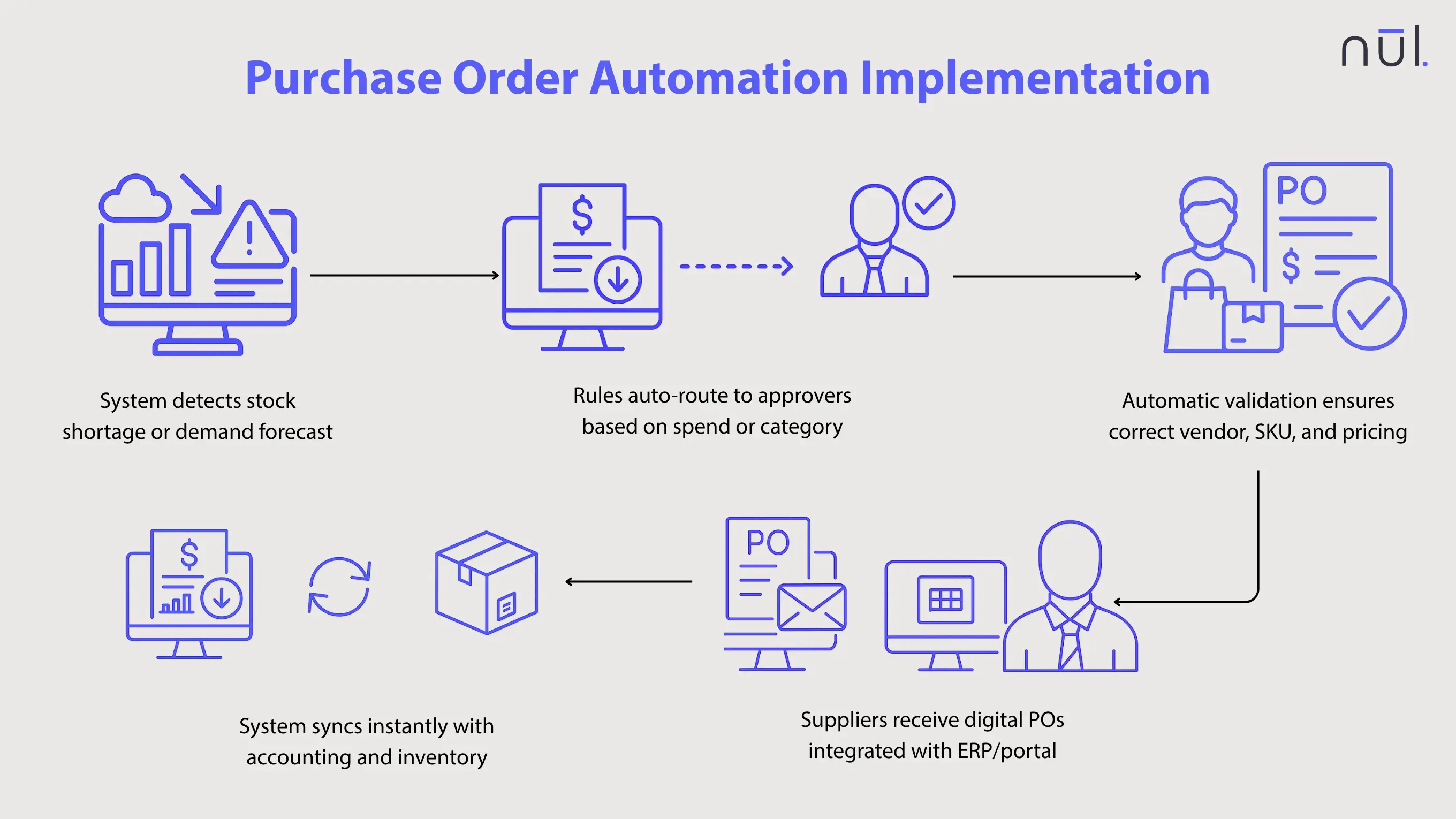

Buyer manually creates a PO in Excel or ERP | System detects stock shortage or demand forecast |

Emails sent for approvals | Rules auto-route to approvers based on spend or category |

Finance or procurement teams review and confirm manually | Automatic validation ensures correct vendor, SKU, and pricing |

Supplier receives and acknowledges order | Suppliers receive digital POs integrated with ERP/portal (automatically sent) |

Data updated later | System syncs instantly with accounting and inventory |

The shift reduces friction and builds real-time visibility into spend, supplier performance, and procurement efficiency.

>> Read more: Digital Transformation in Fashion: Benefits, Risks, Examples

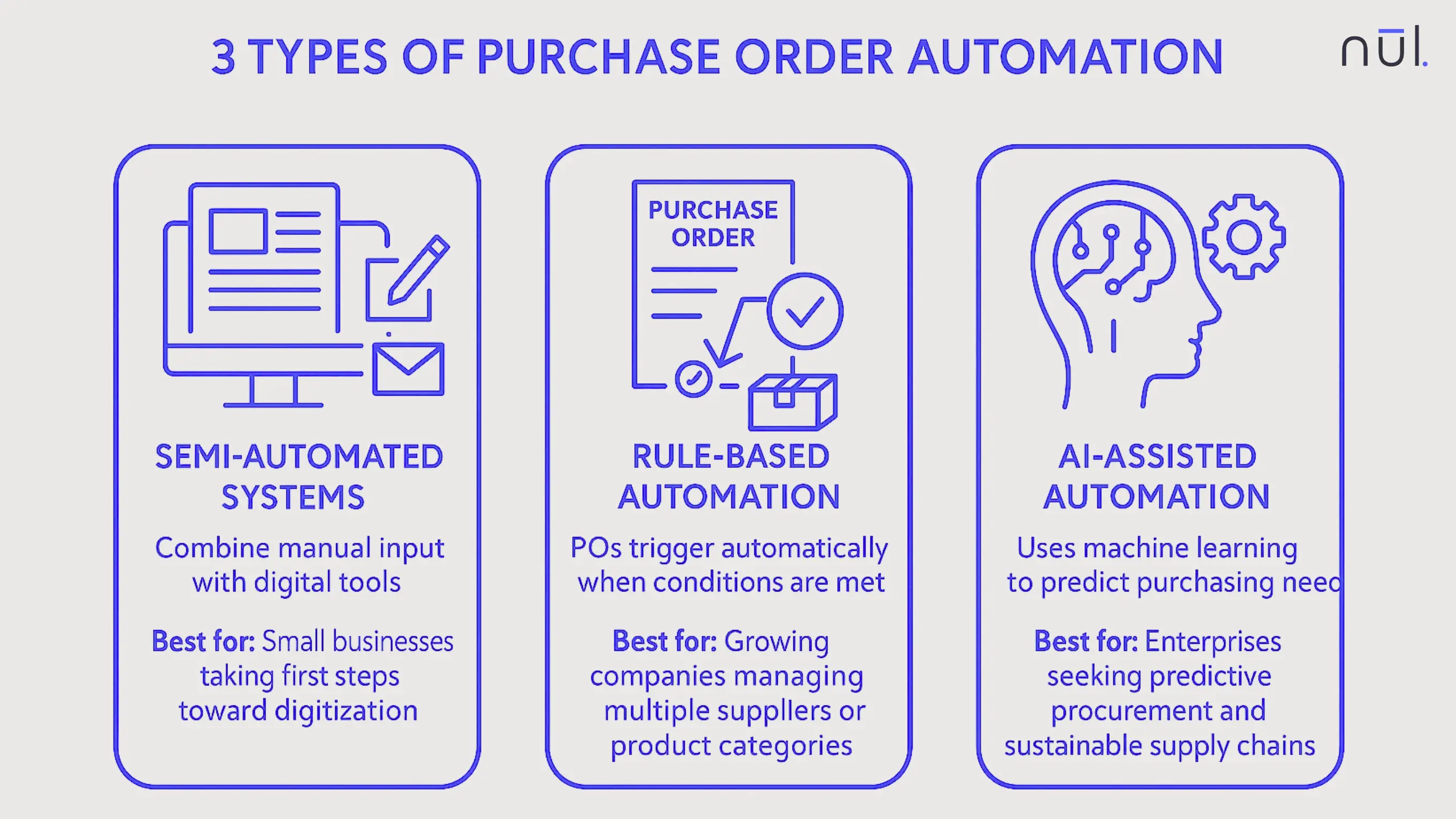

3 Types of Purchase Order Automation

Semi-Automated Systems: Combine manual input with digital tools. Teams still create POs, but templates, data autofill, and email routing reduce repetitive typing and approval delays.

Best for: Small businesses taking first steps toward digitization.

Rule-Based Automation: POs trigger automatically when conditions are met — e.g., stock falls below reorder level or purchase value exceeds limits.

Best for: Growing companies managing multiple suppliers or product categories.

AI-Assisted Automation: Uses machine learning to predict purchasing needs, detect anomalies, and optimize timing. AI can even flag unusual price changes or supplier delays.

Best for: Enterprises seeking predictive procurement and sustainable supply chains.

3 Types of Purchase Order Automation

Benefits of Purchase Order Automation

Eliminate Manual Data Entry – Reduce human error and free teams from repetitive admin.

Speed Up Purchase Cycle Times – Automated routing removes email backlogs and cuts approval bottlenecks.

Improve Accuracy and Compliance – Rules ensure consistent formatting, policy alignment, and audit trails.

Enhance Spend Visibility – Track real-time purchasing data and supplier performance.

Reduce Operational Costs – Lower labor costs and prevent overordering.

Strengthen Supplier Relationships – Faster confirmations and fewer errors build trust.

Enable Better Decisions – Access to clean, structured procurement data improves forecasting.

Simplify Audits and Traceability – Digital records mean transparent, searchable histories.

How to Implement Purchase Order Process Automation?

Assess Current Workflows – Map out how POs are currently created and approved; identify where delays or errors occur.

Define Automation Goals – Clarify what “success” looks like: faster cycle time? fewer errors? better supplier compliance?

Standardize Data and Processes – Align SKUs, supplier codes, and approval hierarchies before introducing automation.

Select the Right Platform – Choose a tool that integrates with your ERP, inventory, or accounting systems.

Configure Rules and Approval Workflows – Set thresholds, exception paths, and roles.

Integrate with Existing Systems – Ensure seamless data sync with finance, inventory, and analytics.

Pilot with a Limited Scope – Test automation with a small product line or supplier set.

Train Teams and Communicate Changes – Encourage adoption by showing tangible benefits.

Monitor Performance and Optimize – Measure approval time, spend accuracy, and order error rates.

Scale and Maintain Governance – As automation expands, regularly audit compliance and update rules.

Purchase Order Automation Implementation

Risks in Purchase Order Automation

Automation brings efficiency — but only when implemented thoughtfully.

Depend on Inaccurate Data: Garbage in, garbage out — automation magnifies data issues. Poor data quality can lead to wrong orders or duplicate POs.

Overlook Exception Scenarios: Not all purchases follow rules; keep flexibility for special cases.

Misconfigure Approval Rules: Poor setup can delay or auto-approve wrongly.

Expose Security Risks: Weak permissions can leak sensitive supplier or spend data.

Face Integration Failures: Systems that don’t sync correctly cause duplicate or missing POs.

Rely Too Heavily on Automation: Human oversight remains essential for judgment calls.

Best Practices for Purchase Order Automation

Align Goals with Business Needs: Automation should solve real procurement challenges, not just speed up tasks. Define what matters most — faster approvals, cleaner data, or better supplier visibility. Clear goals help shape the right workflows and make results measurable.

Keep Humans in the Loop: Even the best systems need oversight. Keep manual checks for high-value or unusual orders where context matters. A short human review can prevent costly mistakes while keeping efficiency high.

Maintain Clean and Accurate Data: Automation is only as smart as the data behind it. Review supplier info, SKUs, and pricing regularly to avoid duplicate or outdated records. Good data keeps your rules reliable and your insights accurate.

Build Flexible Workflows: Procurement evolves fast — your automation should too. Set up workflows that can be adjusted easily as new suppliers, budgets, or product lines appear. Flexibility prevents bottlenecks when business priorities shift.

Collaborate with Suppliers: Bring suppliers into the process through shared dashboards or integrated systems. Real-time visibility on order status and delivery updates helps reduce miscommunication and builds stronger relationships.

Review Exceptions Often: Every exception tells you something. Look for repeated errors or rejections and trace their causes — it could be missing data or outdated rules. Continuous tuning keeps automation smarter and leaner over time.

Track and Use Performance Data: Measure what automation improves. Monitor cycle times, approval delays, and supplier response rates. Use this data to fine-tune rules and report measurable value to finance and operations teams.

Strengthen Compliance Controls: Keep transparency and control front and center. Use role-based approvals, audit trails, and automatic alerts for overspending or policy violations. That keeps your process efficient and accountable.

Involve All Departments: Automation works best when procurement, finance, and operations move in sync. Shared data and input from each team ensure workflows match real needs and avoid confusion later.

Update Rules Regularly: Business rules age quickly. Review thresholds, approval paths, and supplier details at least quarterly to keep automation relevant. Small updates prevent big inefficiencies.

Use AI-Driven PO Automation Software: Move beyond static triggers with AI-powered systems. Machine learning can predict when to buy, spot anomalies, and optimize timing — helping teams stay proactive and keep inventory balanced.

Future Trends of Purchase Order Automation

AI / ML Advances: Predictive ordering, anomaly detection, and intelligent approval suggestions.

Autonomous Procurement Systems: End-to-end systems that execute routine orders independently.

Blockchain & Smart Contracts: Immutable, automated supplier agreements and payment triggers.

Real-Time Supplier Collaboration: Shared visibility, chat-based updates, and dynamic pricing.

IoT Integration: Sensors in warehouses triggering automatic replenishment based on actual usage.

Why Choose Nūl for Purchase Order Automation?

At Nūl, we design intelligent systems that go beyond digitizing purchase orders — we help brands make smarter, waste-free buying decisions.

Our AI-powered inventory and procurement modules integrate seamlessly with your existing systems, automating not just when to buy, but what and how much. From predicting demand to flagging stockouts, Nūl enables a more sustainable, profitable supply chain.

Conclusion

Manual purchase orders belong to another era. In a fast-moving retail landscape, automation isn’t a luxury — it’s the baseline for agility, transparency, and sustainability.

By investing in purchase order process automation, brands can minimize waste, strengthen supplier ties, and redirect human creativity toward higher-value work. Whether you’re a small business or an enterprise, the time to automate is now — and Nūl is here to make it effortless.

Article by

Nūl Content Team

An Experienced Research & Knowledge Team

The Nūl Content Team combines expertise in technology, fashion, and supply chain management to deliver clear, practical insights. Guided by Nūl’s mission to end overproduction, we create content that helps brands forecast demand more accurately, optimize inventory, and build sustainable operations. Every piece we publish is grounded in real-world experience, ensuring it’s both credible and actionable.

LinkedIn Profile

More From Blog

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

More From Blog

How to Automate Purchase Orders? Benefits & Best Practices

Oct 20, 2025

Purchase order automation uses digital systems often powered by AI to automatically generate, route, and approve purchase orders based on set rules or data inputs.

For many fashion and retail businesses, purchase orders (POs) are the lifeblood of production and inventory management. Yet, managing them manually often leads to delays, data entry errors, and compliance headaches.

When every order requires manual review, email threads pile up, spreadsheets get outdated, and approvals stall. The result? Lost time, miscommunication with suppliers, and stock imbalances that impact both profits and sustainability goals.

That’s where purchase order automation steps in — a smarter way to handle procurement. In this guide, we’ll break down what it means, the benefits, and how to implement it effectively — with insights from how modern AI-driven tools streamline the process.

What is Purchase Order Automation?

Purchase order automation uses digital systems — often powered by AI — to automatically generate, route, and approve purchase orders based on predefined rules or data inputs.

Traditional PO | Automated PO |

|---|---|

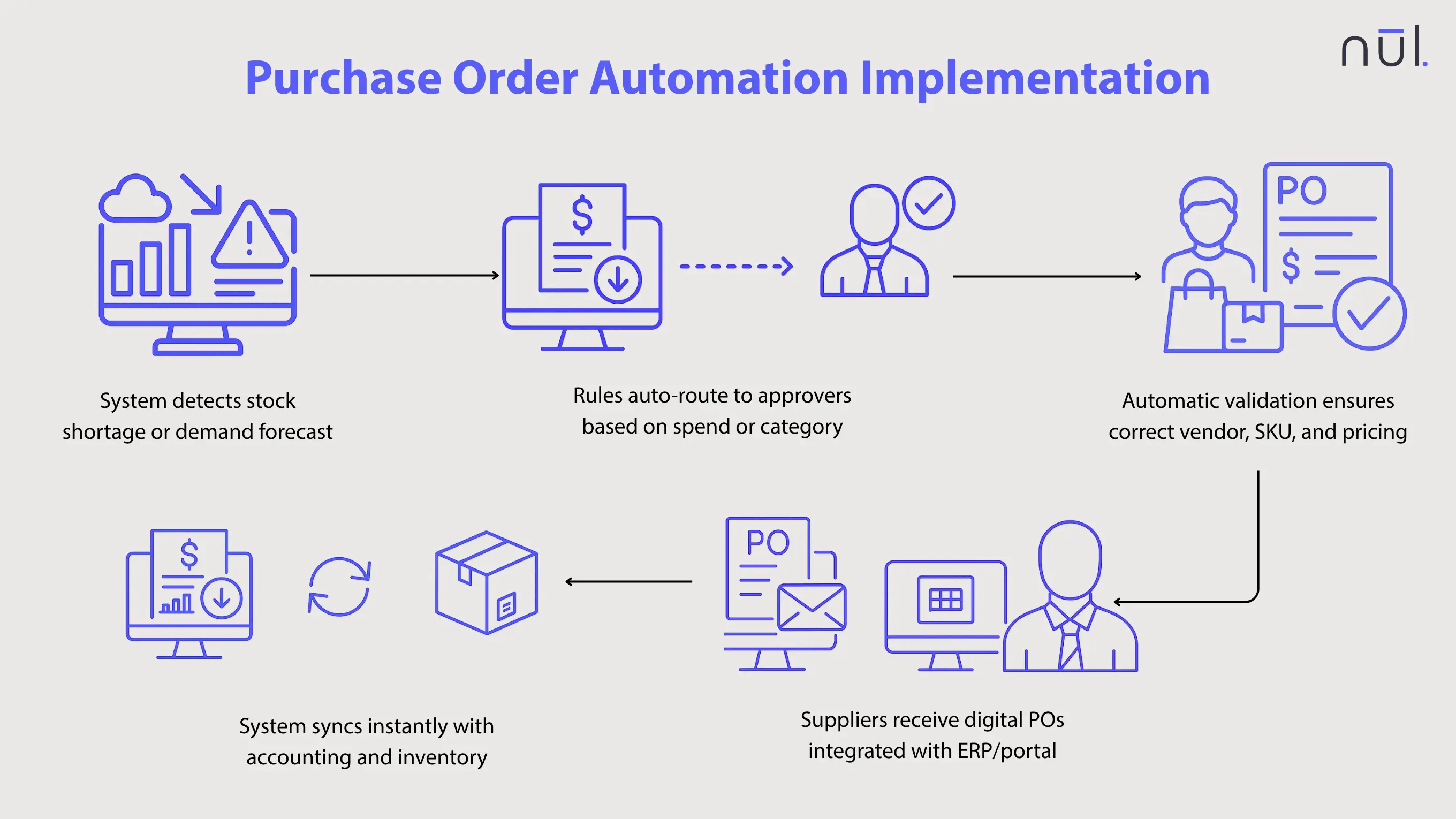

Buyer manually creates a PO in Excel or ERP | System detects stock shortage or demand forecast |

Emails sent for approvals | Rules auto-route to approvers based on spend or category |

Finance or procurement teams review and confirm manually | Automatic validation ensures correct vendor, SKU, and pricing |

Supplier receives and acknowledges order | Suppliers receive digital POs integrated with ERP/portal (automatically sent) |

Data updated later | System syncs instantly with accounting and inventory |

The shift reduces friction and builds real-time visibility into spend, supplier performance, and procurement efficiency.

>> Read more: Digital Transformation in Fashion: Benefits, Risks, Examples

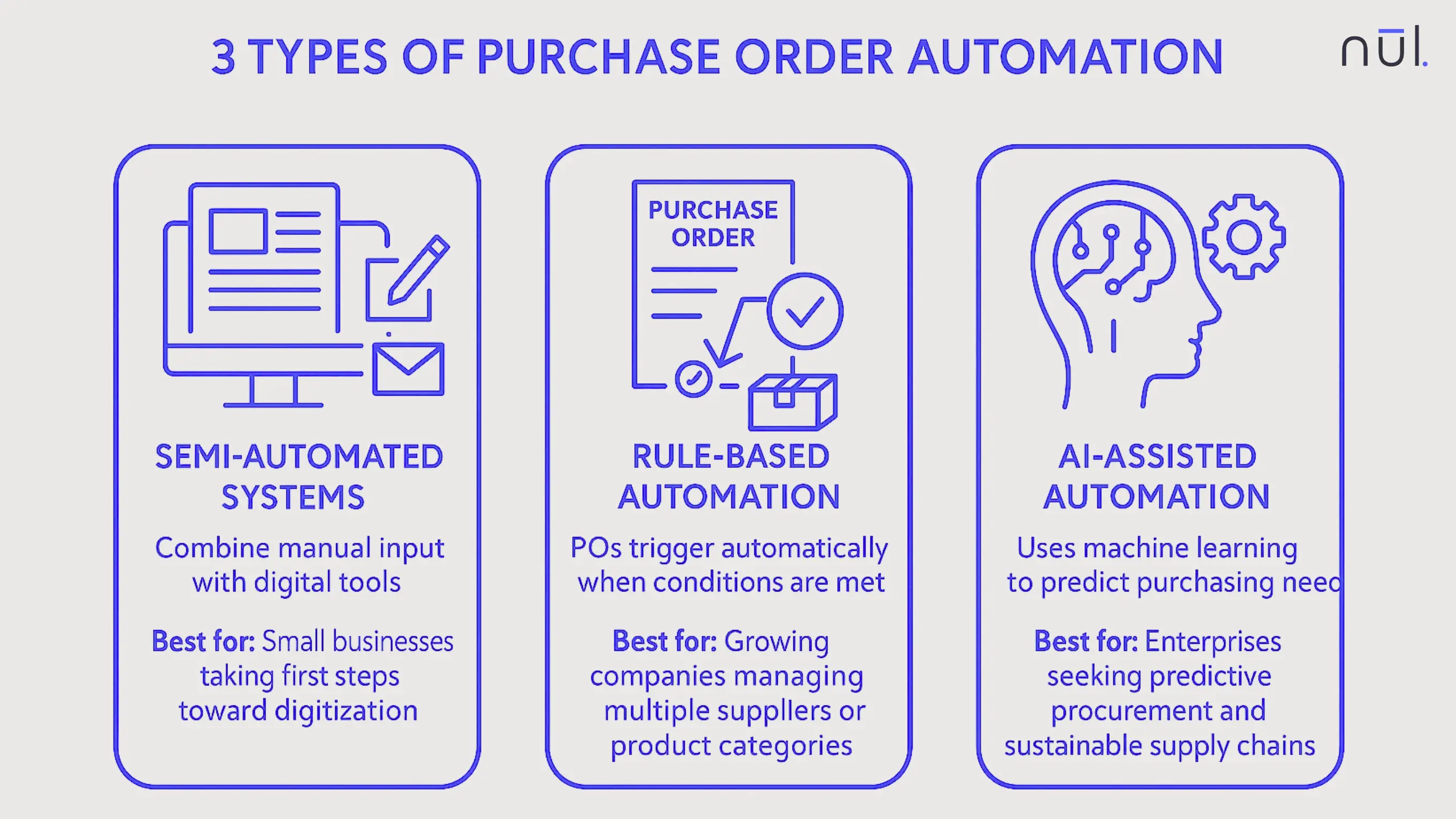

3 Types of Purchase Order Automation

Semi-Automated Systems: Combine manual input with digital tools. Teams still create POs, but templates, data autofill, and email routing reduce repetitive typing and approval delays.

Best for: Small businesses taking first steps toward digitization.

Rule-Based Automation: POs trigger automatically when conditions are met — e.g., stock falls below reorder level or purchase value exceeds limits.

Best for: Growing companies managing multiple suppliers or product categories.

AI-Assisted Automation: Uses machine learning to predict purchasing needs, detect anomalies, and optimize timing. AI can even flag unusual price changes or supplier delays.

Best for: Enterprises seeking predictive procurement and sustainable supply chains.

3 Types of Purchase Order Automation

Benefits of Purchase Order Automation

Eliminate Manual Data Entry – Reduce human error and free teams from repetitive admin.

Speed Up Purchase Cycle Times – Automated routing removes email backlogs and cuts approval bottlenecks.

Improve Accuracy and Compliance – Rules ensure consistent formatting, policy alignment, and audit trails.

Enhance Spend Visibility – Track real-time purchasing data and supplier performance.

Reduce Operational Costs – Lower labor costs and prevent overordering.

Strengthen Supplier Relationships – Faster confirmations and fewer errors build trust.

Enable Better Decisions – Access to clean, structured procurement data improves forecasting.

Simplify Audits and Traceability – Digital records mean transparent, searchable histories.

How to Implement Purchase Order Process Automation?

Assess Current Workflows – Map out how POs are currently created and approved; identify where delays or errors occur.

Define Automation Goals – Clarify what “success” looks like: faster cycle time? fewer errors? better supplier compliance?

Standardize Data and Processes – Align SKUs, supplier codes, and approval hierarchies before introducing automation.

Select the Right Platform – Choose a tool that integrates with your ERP, inventory, or accounting systems.

Configure Rules and Approval Workflows – Set thresholds, exception paths, and roles.

Integrate with Existing Systems – Ensure seamless data sync with finance, inventory, and analytics.

Pilot with a Limited Scope – Test automation with a small product line or supplier set.

Train Teams and Communicate Changes – Encourage adoption by showing tangible benefits.

Monitor Performance and Optimize – Measure approval time, spend accuracy, and order error rates.

Scale and Maintain Governance – As automation expands, regularly audit compliance and update rules.

Purchase Order Automation Implementation

Risks in Purchase Order Automation

Automation brings efficiency — but only when implemented thoughtfully.

Depend on Inaccurate Data: Garbage in, garbage out — automation magnifies data issues. Poor data quality can lead to wrong orders or duplicate POs.

Overlook Exception Scenarios: Not all purchases follow rules; keep flexibility for special cases.

Misconfigure Approval Rules: Poor setup can delay or auto-approve wrongly.

Expose Security Risks: Weak permissions can leak sensitive supplier or spend data.

Face Integration Failures: Systems that don’t sync correctly cause duplicate or missing POs.

Rely Too Heavily on Automation: Human oversight remains essential for judgment calls.

Best Practices for Purchase Order Automation

Align Goals with Business Needs: Automation should solve real procurement challenges, not just speed up tasks. Define what matters most — faster approvals, cleaner data, or better supplier visibility. Clear goals help shape the right workflows and make results measurable.

Keep Humans in the Loop: Even the best systems need oversight. Keep manual checks for high-value or unusual orders where context matters. A short human review can prevent costly mistakes while keeping efficiency high.

Maintain Clean and Accurate Data: Automation is only as smart as the data behind it. Review supplier info, SKUs, and pricing regularly to avoid duplicate or outdated records. Good data keeps your rules reliable and your insights accurate.

Build Flexible Workflows: Procurement evolves fast — your automation should too. Set up workflows that can be adjusted easily as new suppliers, budgets, or product lines appear. Flexibility prevents bottlenecks when business priorities shift.

Collaborate with Suppliers: Bring suppliers into the process through shared dashboards or integrated systems. Real-time visibility on order status and delivery updates helps reduce miscommunication and builds stronger relationships.

Review Exceptions Often: Every exception tells you something. Look for repeated errors or rejections and trace their causes — it could be missing data or outdated rules. Continuous tuning keeps automation smarter and leaner over time.

Track and Use Performance Data: Measure what automation improves. Monitor cycle times, approval delays, and supplier response rates. Use this data to fine-tune rules and report measurable value to finance and operations teams.

Strengthen Compliance Controls: Keep transparency and control front and center. Use role-based approvals, audit trails, and automatic alerts for overspending or policy violations. That keeps your process efficient and accountable.

Involve All Departments: Automation works best when procurement, finance, and operations move in sync. Shared data and input from each team ensure workflows match real needs and avoid confusion later.

Update Rules Regularly: Business rules age quickly. Review thresholds, approval paths, and supplier details at least quarterly to keep automation relevant. Small updates prevent big inefficiencies.

Use AI-Driven PO Automation Software: Move beyond static triggers with AI-powered systems. Machine learning can predict when to buy, spot anomalies, and optimize timing — helping teams stay proactive and keep inventory balanced.

Future Trends of Purchase Order Automation

AI / ML Advances: Predictive ordering, anomaly detection, and intelligent approval suggestions.

Autonomous Procurement Systems: End-to-end systems that execute routine orders independently.

Blockchain & Smart Contracts: Immutable, automated supplier agreements and payment triggers.

Real-Time Supplier Collaboration: Shared visibility, chat-based updates, and dynamic pricing.

IoT Integration: Sensors in warehouses triggering automatic replenishment based on actual usage.

Why Choose Nūl for Purchase Order Automation?

At Nūl, we design intelligent systems that go beyond digitizing purchase orders — we help brands make smarter, waste-free buying decisions.

Our AI-powered inventory and procurement modules integrate seamlessly with your existing systems, automating not just when to buy, but what and how much. From predicting demand to flagging stockouts, Nūl enables a more sustainable, profitable supply chain.

Conclusion

Manual purchase orders belong to another era. In a fast-moving retail landscape, automation isn’t a luxury — it’s the baseline for agility, transparency, and sustainability.

By investing in purchase order process automation, brands can minimize waste, strengthen supplier ties, and redirect human creativity toward higher-value work. Whether you’re a small business or an enterprise, the time to automate is now — and Nūl is here to make it effortless.

Article by

Nūl Content Team

An Experienced Research & Knowledge Team

An Experienced Research & Knowledge Team

The Nūl Content Team combines expertise in technology, fashion, and supply chain management to deliver clear, practical insights. Guided by Nūl’s mission to end overproduction, we create content that helps brands forecast demand more accurately, optimize inventory, and build sustainable operations. Every piece we publish is grounded in real-world experience, ensuring it’s both credible and actionable.

LinkedIn Profile