How Can AI Contribute to Sustainable Fashion? Tech & Challenges

Feb 13, 2026

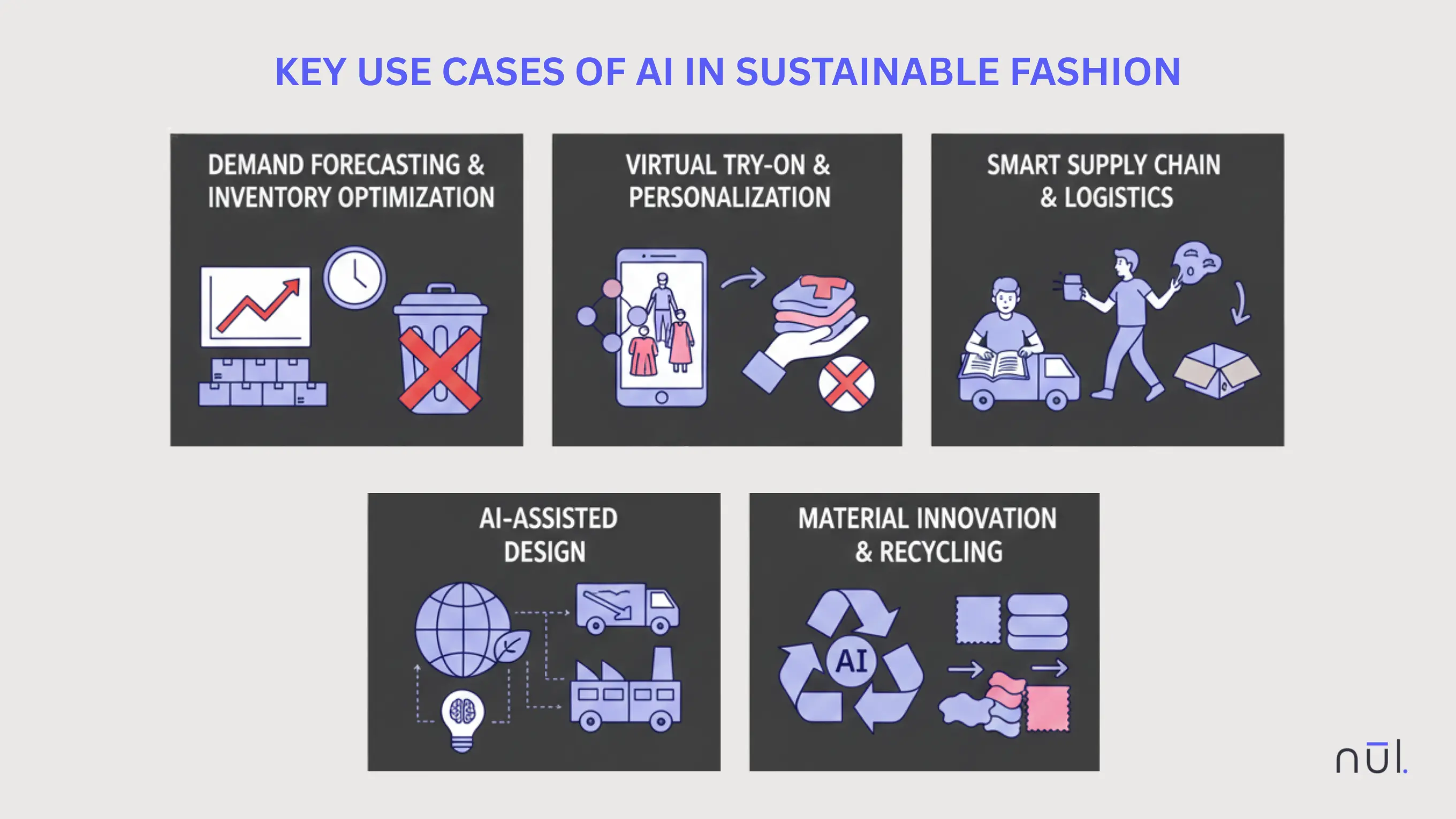

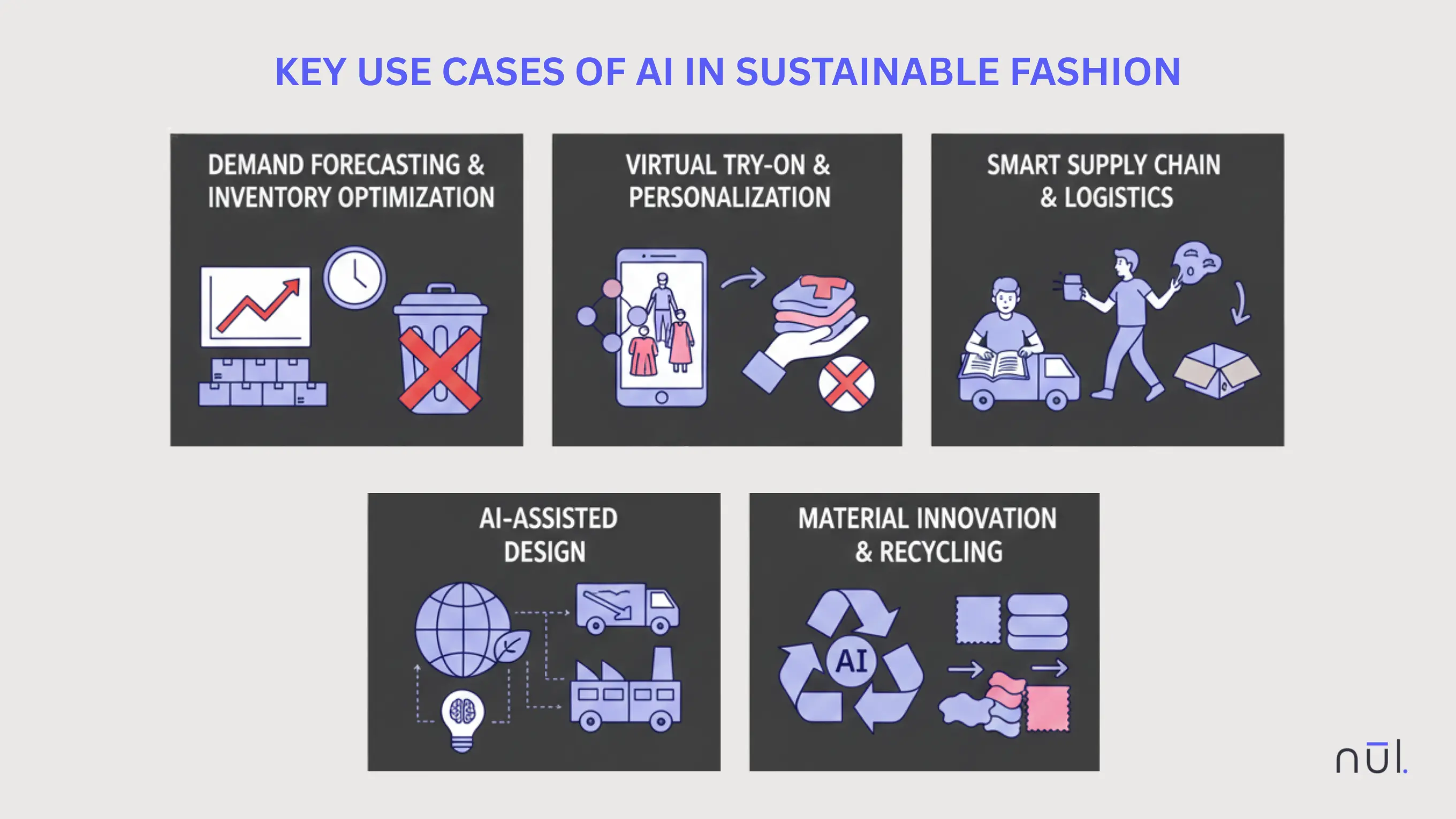

Demand forecasting, inventory optimization, virtual try-on, smart supply chain, material recycling, AI-assisted design, etc are use cases of AI in sustainable fashion.

The fashion industry is under growing pressure to reduce waste, lower emissions, and prove that its products are made responsibly. Traditional management methods with slow processes and incomplete data can't meet the sustainability demand in fashion anymore.

As supply chains are more and more complex with rising consumer expectations, brands need smarter systems that can analyze large amounts of information quickly and accurately. AI is now the most optimal solution for this need.

In this blog, we’ll explore how AI is transforming sustainable fashion across the entire product lifecycle, and what that means for brands, consumers, and the future of the industry.

Key Use Cases of AI in Sustainable Fashion

Demand Forecasting & Inventory Optimization

AI/ML models can analyze sales history, seasonal demand, weather patterns, search trends, and even social media signals to predict what customers will actually buy. With better forecasts, brands can produce closer to real demand and avoid unnecessary manufacturing.

AI prediction models reduce environmental impact by solving the root cause of fashion waste: overproduction. Many brands still produce based on rough estimates, which often leads to excess stock that ends up discounted, destroyed, or unused.

Real Examples:

H&M: Uses AI-driven analytics to predict cultural trends and adjust collection sizes accordingly.

Zara: Monitors real-time inventory and demand data to enable a one-week turnaround from design to store.

>> Read more:

Virtual Try-On & Personalization

Augmented Reality (AR) and AI fittings simulate garment fit and drape onto 3D avatars to replace physical samples. They also scan body dimensions or use uploaded photos to recommend the best size and fit. This reduces incorrect size purchases and returned items that cannot be resold as new and eventually become landfill waste.

Real Examples:

Nike: Its mobile app uses 3D scanning to measure feet with 99% fit accuracy

DressX: A digital fashion platform that lets users try on luxury outfits virtually using an AI twin.

ASOS: Features a "See My Fit" AR tool that allows online shoppers to visualize garments on different body types, reducing returns by up to 22%.

Smart Supply Chain & Logistics

AI systems can analyze transportation routes, supplier performance, inventory levels, and production schedules to recommend more efficient logistics plans. Also, automating the collection of multi-tier supplier data can verify sustainability claims and detect risks like labor violations or environmental damage.

As fashion supply chains span multiple countries and suppliers, companies need such a smart tool to lower fuel use, avoid rush shipments, and reduce idle inventory sitting in warehouses.

Some brands use generative AI models to simulate different shipping scenarios and choose the option with the lowest environmental impact while still meeting delivery deadlines.

Real Examples:

Stella McCartney: Uses AI-powered mapping to track raw materials from farm to factory.

Farfetch: Leverages AI to assess the sustainability credentials of its suppliers and ensure responsible sourcing across its platform.

Material Innovation & Recycling

AI speeds up the transition to a circular economy by automating the identification and sorting of complex textile waste. Specifically, computer vision and NIR spectroscopy can differentiate fabric types, colors, and material compositions, making automated sorting possible. Thus, more and more garments are reused or recycled instead of discarded.

Real Examples:

H&M Foundation & HKRITA: Developing a Smart Garment Sorting System that achieves 96% accuracy in identifying fiber composition and structures in post-consumer waste.

Sortile: Harnesses machine learning and spectroscopy to identify over five different fiber compositions with 95% accuracy, eliminating the need for manual tag checking.

AI-Assisted Design

Generative AI tools can help designers test multiple pattern layouts, fabric combinations, and construction options digitally before producing physical samples. This reduces fabric waste, shortens development time, and lowers the environmental footprint of prototyping.

Some design platforms use generative models to suggest pattern placements that maximize fabric usage, helping teams choose layouts that minimize leftover material during cutting.

Real Examples:

Adidas: Integrates AI into design and virtual sampling, reducing physical prototypes by 65% and speeding up development by 50%.

Tommy Hilfiger: Uses AI to analyze vast trend data and suggest design elements, allowing designers to experiment with styles virtually before any fabric is cut.

Key Use Cases of AI in Sustainable Fashion

Core AI Technologies Powering Sustainable Fashion Systems

>> Read more: Top 10 Fashion Tech Trends Every Brand Should Know

Machine Learning & Data Analytics

Demand Forecasting: Processes historical sales, social media sentiment, and weather patterns to align production with actual market demand

Trend Prediction: Identifies emerging styles with high accuracy, allowing designers to focus on items consumers actually want.

Supply Chain Risk Assessment: Monitors vast datasets, including satellite imagery and worker pay records, to flag anomalies linked to labor violations or environmental damage.

Material Selection: Analyzes supplier data to identify eco-friendly alternatives like organic cotton and bio-fabrics that match specific design requirements.

Computer Vision

Automated Defect Detection: High-resolution cameras scan fabrics during production to identify minute flaws (holes, scratches, color bleeding) in real-time, preventing material waste downstream.

Textile Sorting for Recycling: Uses NIR spectroscopy and image recognition to identify fiber composition (e.g., separating cotton from polyester).

Quality Assurance: Maintains consistent 24/7 inspection standards without the human error or fatigue typical of manual checks.

Generative AI

Virtual Prototyping: Converts text or sketches into high-fidelity 3D digital garments.

Zero-Waste Pattern Generation: Optimizes pattern layouts on fabric rolls to maximize utilization and minimize scrap material during the cutting phase.

Design Augmentation: Analyzes trend reports and runway data to suggest functional, environmentally responsible design variations faster than traditional methods.

Digital Twins & Simulation

Garment Lifecycle Twinning: Creates dynamic virtual replicas of garments that store "digital product passport" data, tracking everything from raw material origin to repair history.

Production Line Simulation: Mirrors physical factory operations in real-time to anticipate equipment maintenance needs and optimize energy or water usage.

Fabric Behavior Testing: Simulates how different sustainable fabrics drape and move on various 3D body types, reducing size-related returns and waste.

Scenario Modeling: Tests the environmental impact of potential sourcing or production decisions virtually before they are implemented physically.

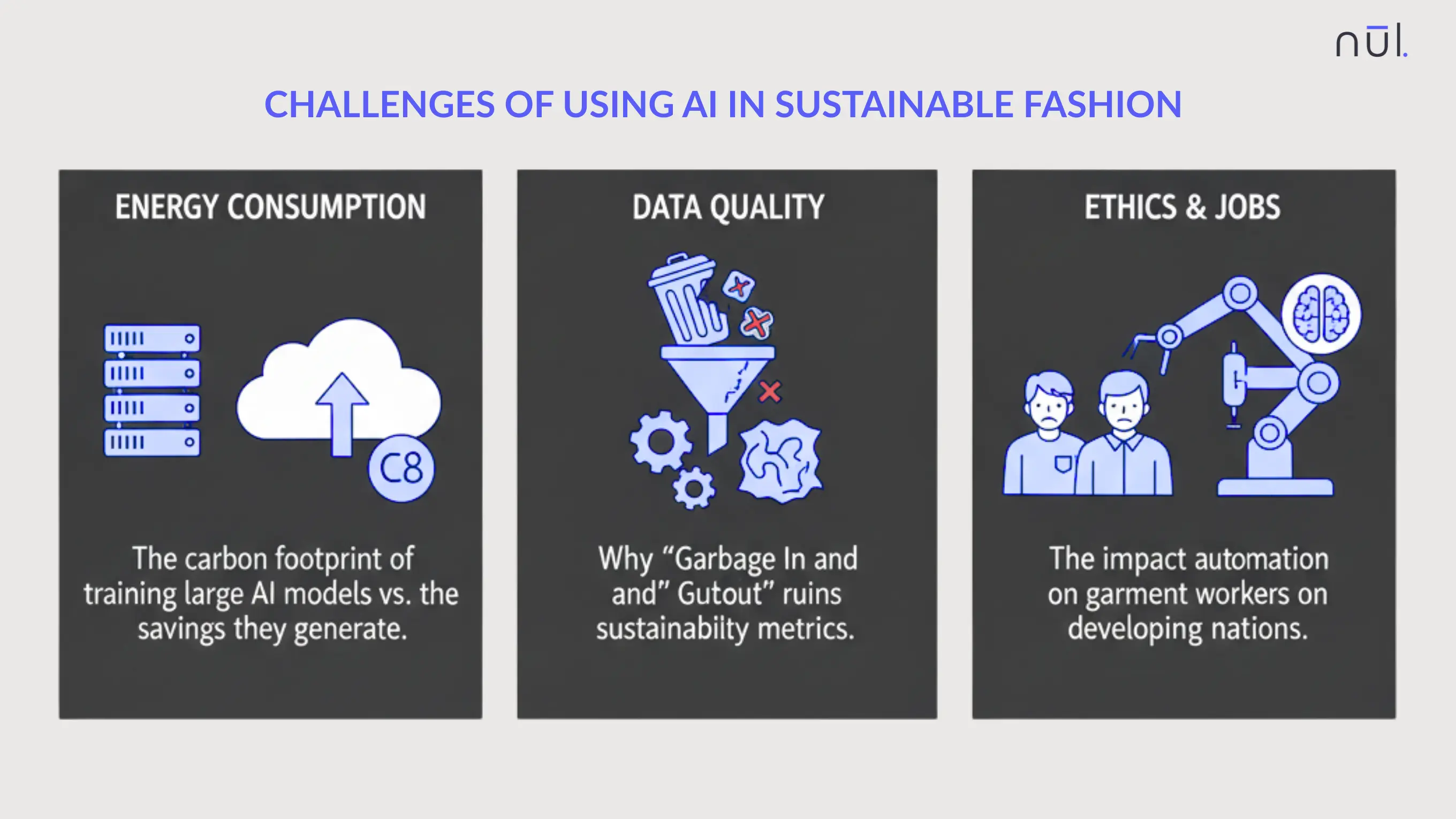

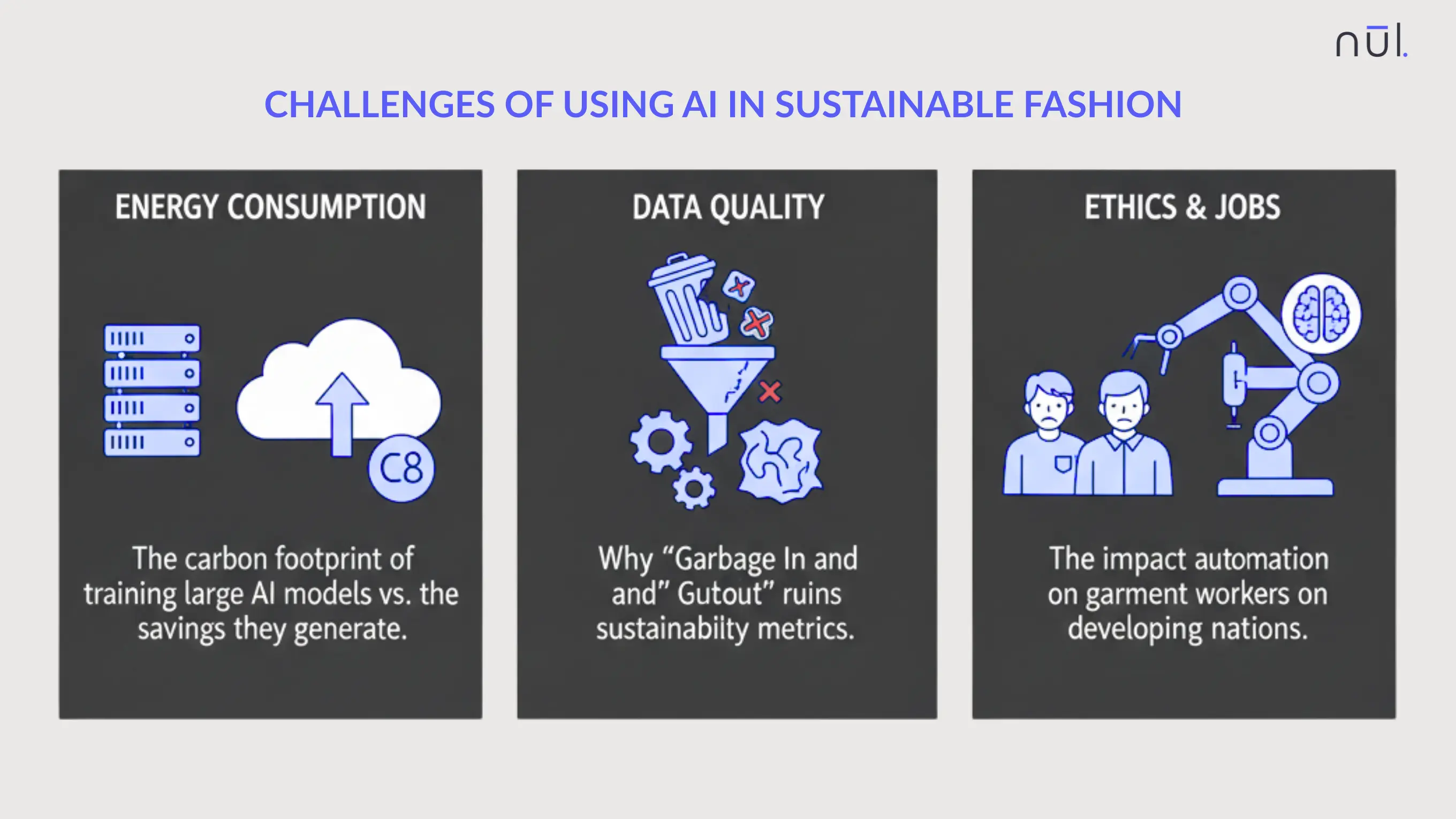

Challenges of Using AI in Sustainable Fashion

Although AI can support more responsible fashion systems, it also introduces real technical and social challenges. Below are three core issues brands and technology teams must consider before relying heavily on AI-driven solutions.

Energy Consumption

Training large AI models takes large computing power. Those systems run on servers that use electricity and cooling, which can increase carbon emissions if the energy source isn’t clean. So the pollution it creates can sometimes reduce the environmental benefits it was meant to provide.

This doesn’t mean AI is harmful, it just means companies need to think carefully about efficiency, model size, and infrastructure. Choosing energy-efficient hardware or greener data centers can make a big difference.

Data Quality

AI systems rely entirely on data to function. If the data used to train models is incomplete, outdated, or inaccurate, the system’s outputs will also be unreliable. In sustainability contexts, poor data can distort impact measurements, misrepresent supplier practices, or produce misleading environmental metrics.

This problem is often summarized as “garbage in, garbage out,” meaning the system cannot produce trustworthy insights if its inputs are flawed. In short, sustainability claims generated by AI are only as credible as the data sources behind them, so data governance and validation are essential.

Ethics & Jobs

Automation can reshape labor demand across the fashion supply chain. In regions where garment production provides employment for large populations, increased automation could reduce certain types of manual work.

This creates social sustainability concerns alongside environmental ones. The issue is not simply job loss, but how technology shifts skill requirements, wages, and working conditions. Responsible implementation requires planning for workforce transition, retraining opportunities, and fair labor practices.

Challenges of Using AI in Sustainable Fashion

Conclusion

The integration of Artificial Intelligence into the fashion industry represents a critical turning point in the pursuit of a truly circular and sustainable economy.

However, AI is not a shortcut to sustainability on its own. Its real value depends on responsible implementation. It is a practical tool, but not by replacing human decisions, but by helping brands understand their data, predict outcomes, and act earlier.

Just by approaching AI with a balanced mindset, brands can build solutions that are not only innovative, but also genuinely sustainable for the long term.

Article by

Nūl Content Team

An Experienced Research & Knowledge Team

The Nūl Content Team combines expertise in technology, fashion, and supply chain management to deliver clear, practical insights. Guided by Nūl’s mission to end overproduction, we create content that helps brands forecast demand more accurately, optimize inventory, and build sustainable operations. Every piece we publish is grounded in real-world experience, ensuring it’s both credible and actionable.

LinkedIn Profile

More From Blog

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

More From Blog

How Can AI Contribute to Sustainable Fashion? Tech & Challenges

Feb 13, 2026

Demand forecasting, inventory optimization, virtual try-on, smart supply chain, material recycling, AI-assisted design, etc are use cases of AI in sustainable fashion.

The fashion industry is under growing pressure to reduce waste, lower emissions, and prove that its products are made responsibly. Traditional management methods with slow processes and incomplete data can't meet the sustainability demand in fashion anymore.

As supply chains are more and more complex with rising consumer expectations, brands need smarter systems that can analyze large amounts of information quickly and accurately. AI is now the most optimal solution for this need.

In this blog, we’ll explore how AI is transforming sustainable fashion across the entire product lifecycle, and what that means for brands, consumers, and the future of the industry.

Key Use Cases of AI in Sustainable Fashion

Demand Forecasting & Inventory Optimization

AI/ML models can analyze sales history, seasonal demand, weather patterns, search trends, and even social media signals to predict what customers will actually buy. With better forecasts, brands can produce closer to real demand and avoid unnecessary manufacturing.

AI prediction models reduce environmental impact by solving the root cause of fashion waste: overproduction. Many brands still produce based on rough estimates, which often leads to excess stock that ends up discounted, destroyed, or unused.

Real Examples:

H&M: Uses AI-driven analytics to predict cultural trends and adjust collection sizes accordingly.

Zara: Monitors real-time inventory and demand data to enable a one-week turnaround from design to store.

>> Read more:

Virtual Try-On & Personalization

Augmented Reality (AR) and AI fittings simulate garment fit and drape onto 3D avatars to replace physical samples. They also scan body dimensions or use uploaded photos to recommend the best size and fit. This reduces incorrect size purchases and returned items that cannot be resold as new and eventually become landfill waste.

Real Examples:

Nike: Its mobile app uses 3D scanning to measure feet with 99% fit accuracy

DressX: A digital fashion platform that lets users try on luxury outfits virtually using an AI twin.

ASOS: Features a "See My Fit" AR tool that allows online shoppers to visualize garments on different body types, reducing returns by up to 22%.

Smart Supply Chain & Logistics

AI systems can analyze transportation routes, supplier performance, inventory levels, and production schedules to recommend more efficient logistics plans. Also, automating the collection of multi-tier supplier data can verify sustainability claims and detect risks like labor violations or environmental damage.

As fashion supply chains span multiple countries and suppliers, companies need such a smart tool to lower fuel use, avoid rush shipments, and reduce idle inventory sitting in warehouses.

Some brands use generative AI models to simulate different shipping scenarios and choose the option with the lowest environmental impact while still meeting delivery deadlines.

Real Examples:

Stella McCartney: Uses AI-powered mapping to track raw materials from farm to factory.

Farfetch: Leverages AI to assess the sustainability credentials of its suppliers and ensure responsible sourcing across its platform.

Material Innovation & Recycling

AI speeds up the transition to a circular economy by automating the identification and sorting of complex textile waste. Specifically, computer vision and NIR spectroscopy can differentiate fabric types, colors, and material compositions, making automated sorting possible. Thus, more and more garments are reused or recycled instead of discarded.

Real Examples:

H&M Foundation & HKRITA: Developing a Smart Garment Sorting System that achieves 96% accuracy in identifying fiber composition and structures in post-consumer waste.

Sortile: Harnesses machine learning and spectroscopy to identify over five different fiber compositions with 95% accuracy, eliminating the need for manual tag checking.

AI-Assisted Design

Generative AI tools can help designers test multiple pattern layouts, fabric combinations, and construction options digitally before producing physical samples. This reduces fabric waste, shortens development time, and lowers the environmental footprint of prototyping.

Some design platforms use generative models to suggest pattern placements that maximize fabric usage, helping teams choose layouts that minimize leftover material during cutting.

Real Examples:

Adidas: Integrates AI into design and virtual sampling, reducing physical prototypes by 65% and speeding up development by 50%.

Tommy Hilfiger: Uses AI to analyze vast trend data and suggest design elements, allowing designers to experiment with styles virtually before any fabric is cut.

Key Use Cases of AI in Sustainable Fashion

Core AI Technologies Powering Sustainable Fashion Systems

>> Read more: Top 10 Fashion Tech Trends Every Brand Should Know

Machine Learning & Data Analytics

Demand Forecasting: Processes historical sales, social media sentiment, and weather patterns to align production with actual market demand

Trend Prediction: Identifies emerging styles with high accuracy, allowing designers to focus on items consumers actually want.

Supply Chain Risk Assessment: Monitors vast datasets, including satellite imagery and worker pay records, to flag anomalies linked to labor violations or environmental damage.

Material Selection: Analyzes supplier data to identify eco-friendly alternatives like organic cotton and bio-fabrics that match specific design requirements.

Computer Vision

Automated Defect Detection: High-resolution cameras scan fabrics during production to identify minute flaws (holes, scratches, color bleeding) in real-time, preventing material waste downstream.

Textile Sorting for Recycling: Uses NIR spectroscopy and image recognition to identify fiber composition (e.g., separating cotton from polyester).

Quality Assurance: Maintains consistent 24/7 inspection standards without the human error or fatigue typical of manual checks.

Generative AI

Virtual Prototyping: Converts text or sketches into high-fidelity 3D digital garments.

Zero-Waste Pattern Generation: Optimizes pattern layouts on fabric rolls to maximize utilization and minimize scrap material during the cutting phase.

Design Augmentation: Analyzes trend reports and runway data to suggest functional, environmentally responsible design variations faster than traditional methods.

Digital Twins & Simulation

Garment Lifecycle Twinning: Creates dynamic virtual replicas of garments that store "digital product passport" data, tracking everything from raw material origin to repair history.

Production Line Simulation: Mirrors physical factory operations in real-time to anticipate equipment maintenance needs and optimize energy or water usage.

Fabric Behavior Testing: Simulates how different sustainable fabrics drape and move on various 3D body types, reducing size-related returns and waste.

Scenario Modeling: Tests the environmental impact of potential sourcing or production decisions virtually before they are implemented physically.

Challenges of Using AI in Sustainable Fashion

Although AI can support more responsible fashion systems, it also introduces real technical and social challenges. Below are three core issues brands and technology teams must consider before relying heavily on AI-driven solutions.

Energy Consumption

Training large AI models takes large computing power. Those systems run on servers that use electricity and cooling, which can increase carbon emissions if the energy source isn’t clean. So the pollution it creates can sometimes reduce the environmental benefits it was meant to provide.

This doesn’t mean AI is harmful, it just means companies need to think carefully about efficiency, model size, and infrastructure. Choosing energy-efficient hardware or greener data centers can make a big difference.

Data Quality

AI systems rely entirely on data to function. If the data used to train models is incomplete, outdated, or inaccurate, the system’s outputs will also be unreliable. In sustainability contexts, poor data can distort impact measurements, misrepresent supplier practices, or produce misleading environmental metrics.

This problem is often summarized as “garbage in, garbage out,” meaning the system cannot produce trustworthy insights if its inputs are flawed. In short, sustainability claims generated by AI are only as credible as the data sources behind them, so data governance and validation are essential.

Ethics & Jobs

Automation can reshape labor demand across the fashion supply chain. In regions where garment production provides employment for large populations, increased automation could reduce certain types of manual work.

This creates social sustainability concerns alongside environmental ones. The issue is not simply job loss, but how technology shifts skill requirements, wages, and working conditions. Responsible implementation requires planning for workforce transition, retraining opportunities, and fair labor practices.

Challenges of Using AI in Sustainable Fashion

Conclusion

The integration of Artificial Intelligence into the fashion industry represents a critical turning point in the pursuit of a truly circular and sustainable economy.

However, AI is not a shortcut to sustainability on its own. Its real value depends on responsible implementation. It is a practical tool, but not by replacing human decisions, but by helping brands understand their data, predict outcomes, and act earlier.

Just by approaching AI with a balanced mindset, brands can build solutions that are not only innovative, but also genuinely sustainable for the long term.

Article by

Nūl Content Team

An Experienced Research & Knowledge Team

An Experienced Research & Knowledge Team

The Nūl Content Team combines expertise in technology, fashion, and supply chain management to deliver clear, practical insights. Guided by Nūl’s mission to end overproduction, we create content that helps brands forecast demand more accurately, optimize inventory, and build sustainable operations. Every piece we publish is grounded in real-world experience, ensuring it’s both credible and actionable.

LinkedIn Profile