7 Best Batch Production Software Solutions for Fashion Brands

Dec 5, 2025

Nūl, ApparelMagic, Katana, BatchMaster, WFX Apparel ERP, Infor, ERPNext are the 7 best batch production software for fashion brands and manufacturers to consider.

These days, fashion brands who have to deal with various styles, colors, and sizes in their seasonal collections need to use batch production as their main workflow. To achieve a seamless and profitable process, brands need specialized software to plan batches, track materials in real-time, control production orders, and maintain visibility from cutting through finishing.

This blog will review top 7 reliable batch production software solutions to assist fashion teams find the best choice to operate their manufacturing processes.

Key Features of Batch Production Software for Fashion

Batch planning: Plan production in precise batches, grouping units by every variant.

Real-time material tracking: Show how much fabric, trims, and accessories are available or reserved for each batch.

Bill of Materials (BOM) management: Calculate costs, link raw materials to each style, and ensure factory teams use the correct components during production.

Production order management: Issue, schedule, and track production orders across multiple factories or suppliers.

Cutting and sewing workflow tracking: Follow each batch as it moves through cutting, sewing, finishing, and packing, giving teams visibility into work-in-progress.

Quality checks and approvals: Allow teams to review samples, track defects, and approve production before moving to the next stage.

Multi-location coordination: Sync batch updates to prevent duplicated production or missing stock across multiple factories or warehouses.

Integrated inventory updates: As batches progress, inventory is updated automatically like finished goods increase, raw materials decrease, and any variance is recorded.

Costing and margin visibility: See how material usage, labor, and batch sizes affect total cost and expected margin per style.

Supplier and factory collaboration: Brands can communicate requirements, track progress, and reduce errors with manufacturing partners via portals and shared workflows.

7 Best Batch Production Software Solutions

Software | Core Focus | Key Features | Best For |

|---|---|---|---|

Nūl | Agentic AI Planning & PPC |

| Fashion brands and manufacturers running many small–medium batches across multiple locations. |

ApparelMagic | Fashion-Native Cloud ERP/PLM |

| Small to larger fashion brands wanting one system for styles, inventory, production, and shipping. |

Katana MRP | Cloud Manufacturing Resource Planning |

| Small–mid apparel/footwear brands doing batch or MTO with omnichannel sales. |

BatchMaster | Process-Centric ERP |

| Apparel manufacturers needing full ERP plus strong batch, lot, and PPC control. |

WFX Apparel ERP | Unified Global Supply Chain Suite |

| Mid–large manufacturers with multi-factory / subcontracting setups |

Infor | Global Enterprise ERP |

| Medium–large global brands needing an integrated enterprise stack. |

ERPNext | Open-Source Full-Suite ERP |

| Small–mid apparel/textile manufacturers wanting flexible, low-license-cost ERP. |

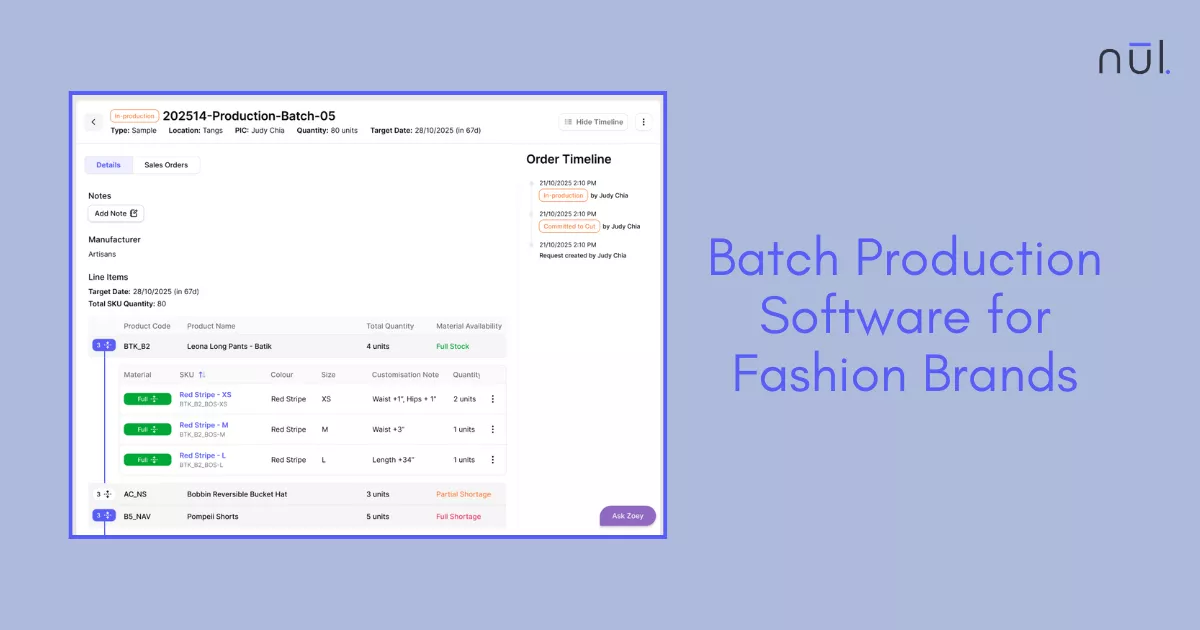

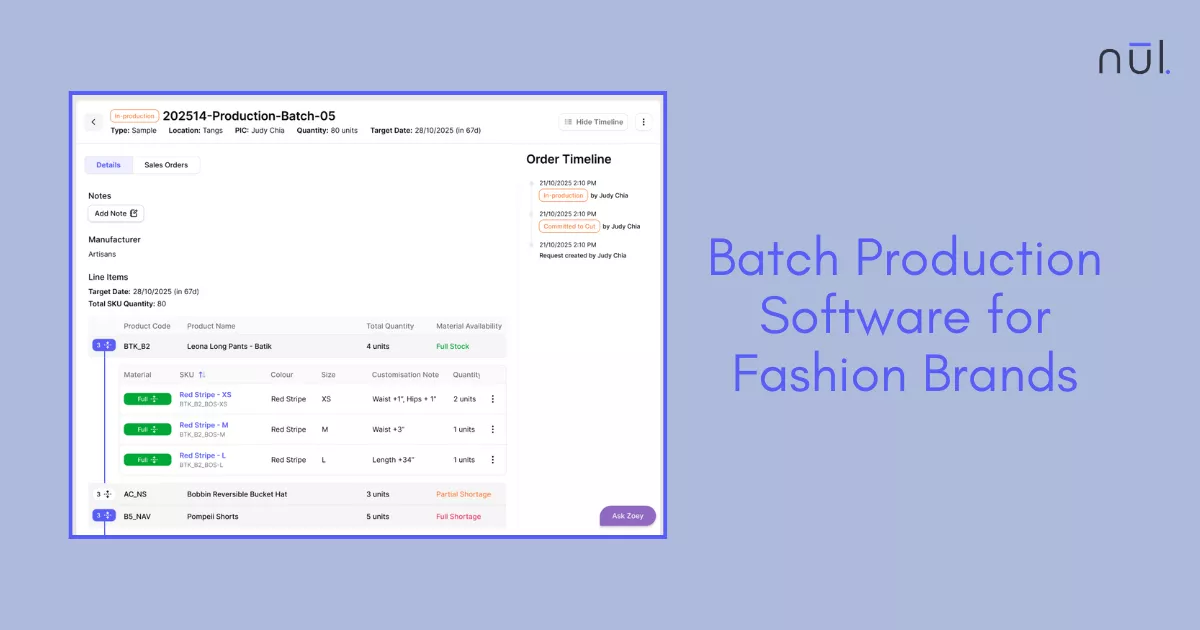

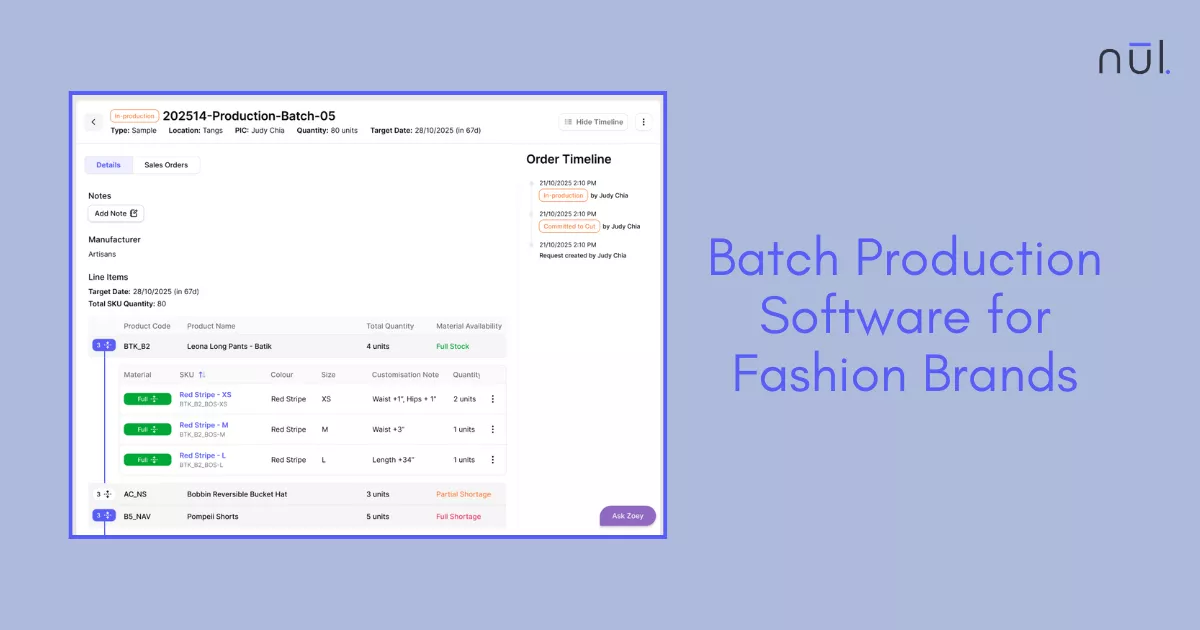

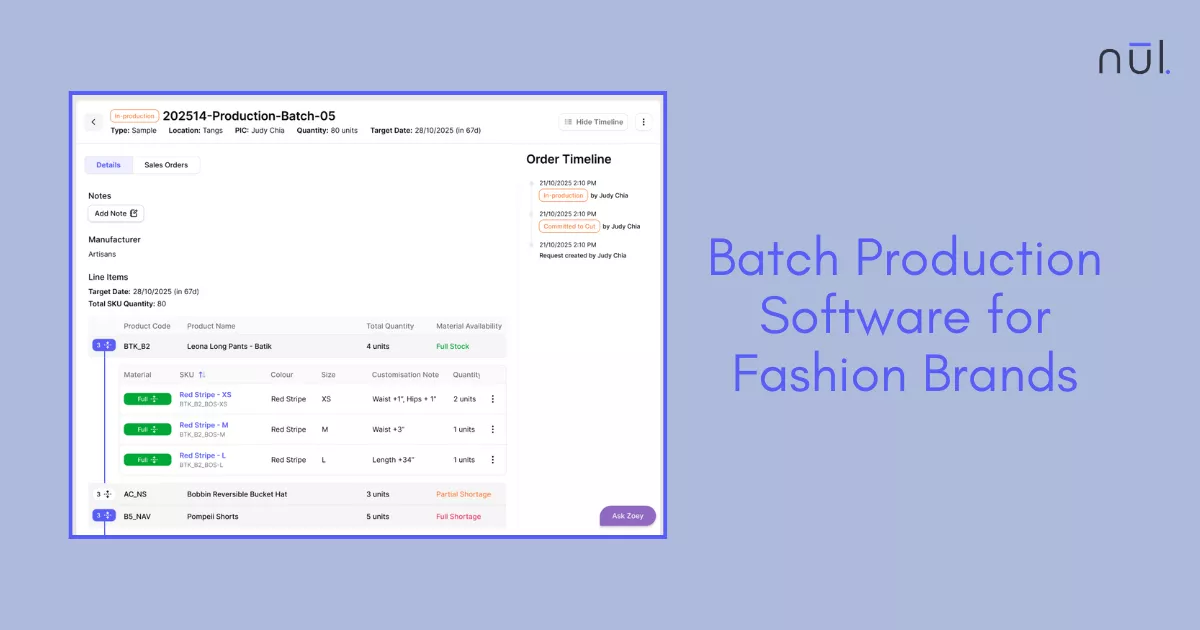

Nūl

Nūl is an Agentic AI platform for inventory optimization and demand planning, with the aim to achieve zero-waste fashion by preventing overproduction. Its Production Planning and Control (PPC) module links AI-driven forecasting with the factory floor for efficient and material-accurate batch manufacturing. In fact, every batch is planned with the right quantities, timing, and materials, so production can maintains healthy inventory levels.

Highlights for batch production:

Production Requests list: with filters by location, type, PIC, and status, so you can quickly isolate, for example, all samples at one factory or all batches committed to cut this week.

SKU-Level Control: Allow production planning for specific line items, managing the mix of Color, Size, and even Customization Notes within a single batch work order.

Real-Time Material Readiness (MRP): Instantly check material inventory against the BOM (Bill of Materials) for the batch. It has clear labels like Full Stock, Partial Shortage, or Full Shortage, detailing the exact material and the precise shortfall.

Traceability and Status: Use an auditable Order Timeline that records every status change (e.g., Committed to Cut, In-production) and tracks the overall Batch Status for quick oversight.

Output tagging for fulfilment: Tags like Full, Partial, and Reserved for finished SKUs, helping teams decide how batch output should be allocated to orders.

Limitation: Nūl is not a complete manufacturing platform or full MES that handles the moment-to-moment management and optimization of the physical production process itself.

Best for: Fashion brands and manufacturers running many small to medium batches (MTO, samples, custom orders) across multiple locations that need SKU-level visibility into status and materials, especially when production is outsourced.

Nūl is an Agentic AI platform with batch production feature. (Source: Nūl)

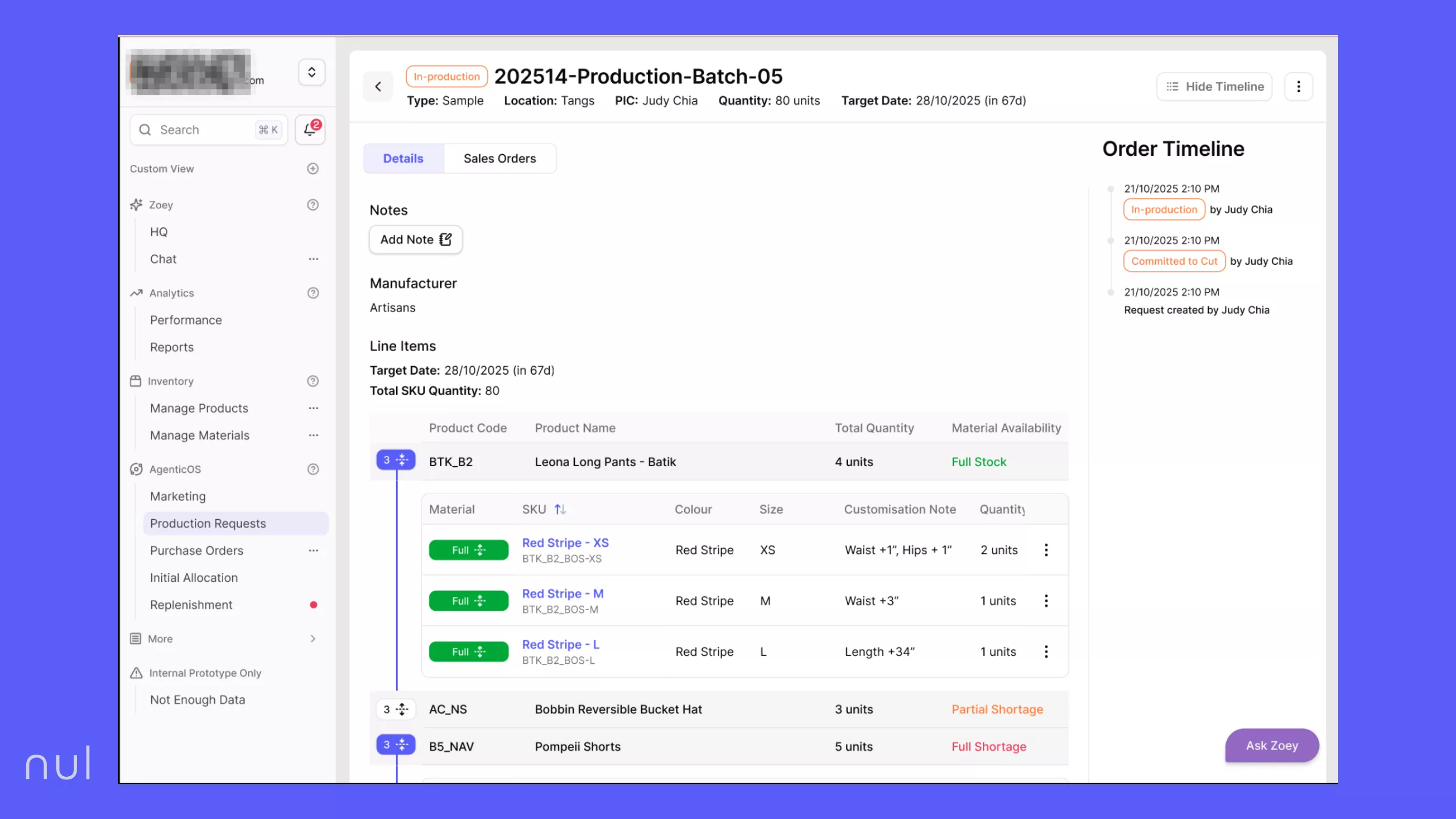

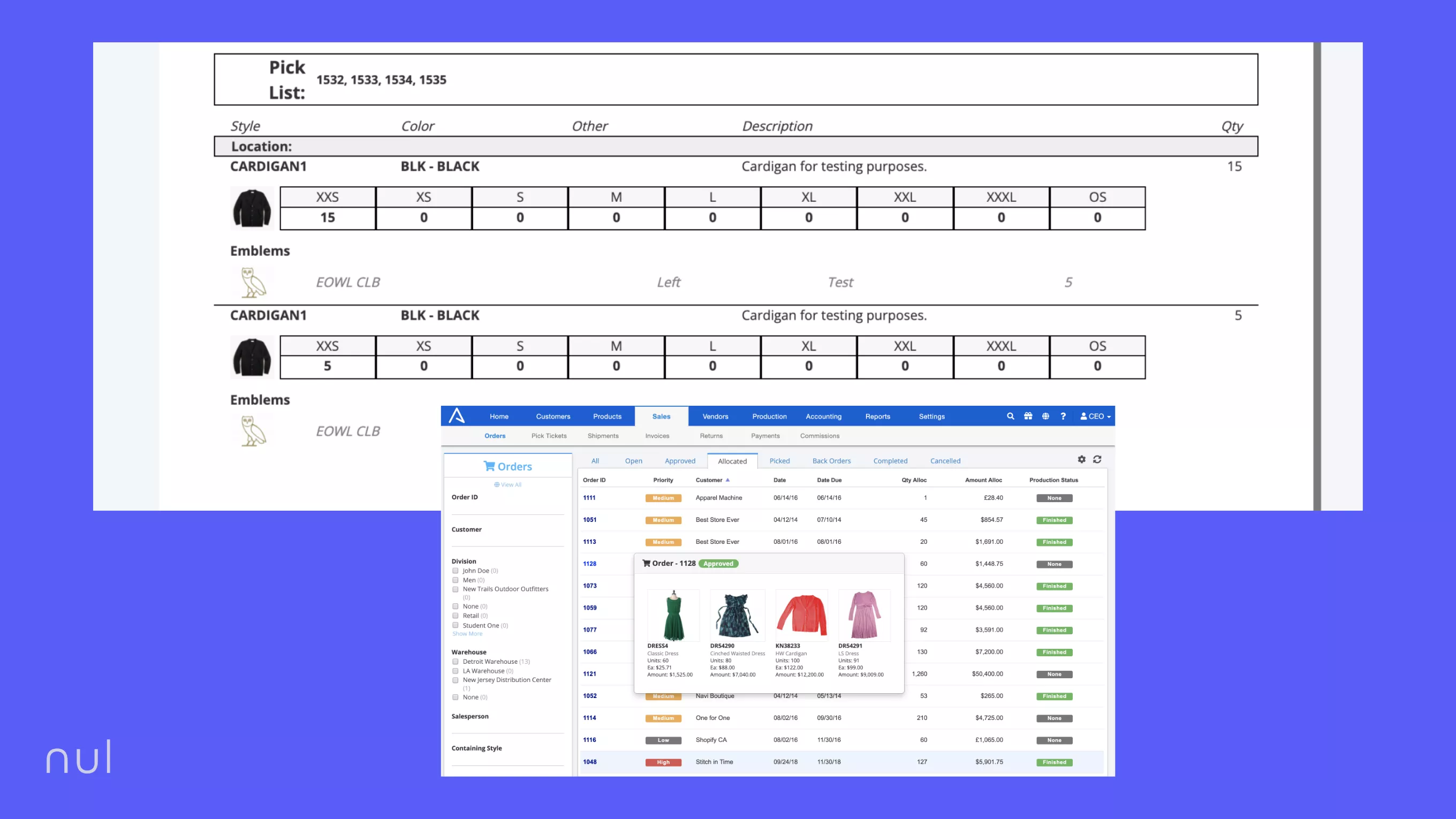

ApparelMagic

ApparelMagic is a cloud-based ERP (Enterprise Resource Planning) platform built for the apparel, accessories, and fashion industries. As an all-in-one solution, it integrates Product Lifecycle Management (PLM), Manufacturing, Inventory Management, Wholesale, and Accounting into a single system.

Highlights for batch production:

Integrated PLM to Production: Link Tech Packs, Bills of Materials (BOMs), and detailed product specifications directly to manufacturing orders. The factory teams can receive accurate instructions and use the correct raw materials for every batch.

WIP and Multi-Stage Tracking: Manage Work-In-Progress (WIP) by tracking production through defined multi-stage manufacturing processes. Planning teams have real-time visibility into the status and location of a batch throughout cutting, sewing, and finishing.

Advanced Fulfillment: Support efficient logistics with Batch Picking (picking multiple sales orders simultaneously) and flexible Allocation Methods, speeding up the order fulfillment process once a production batch is completed and received into inventory.

Robust Size/Color Matrix: Provide support for managing complex product variants, ensuring inventory accuracy and simplifying the planning of units per size run in any batch.

Limitation: May not offer the same level of deep, code-level customization or complex vertical integration for huge global corporations

Best for: Mid-sized and growing fashion brands (both wholesale and DTC) that require an affordable, integrated ERP solution to handle operations from design conception to final delivery.

ApparelMagic is a cloud-based ERP platform. (Source: ApparelMagic)

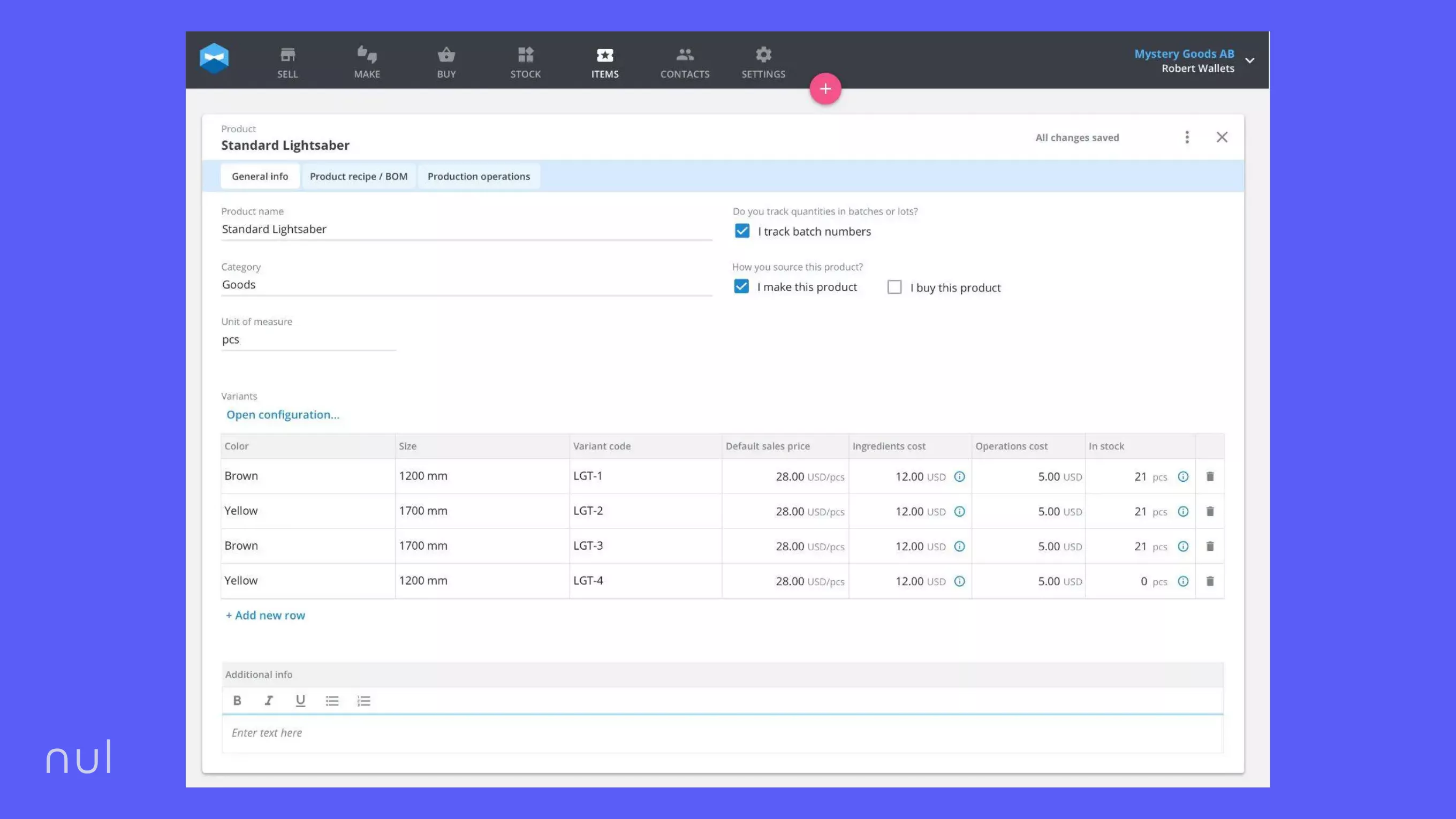

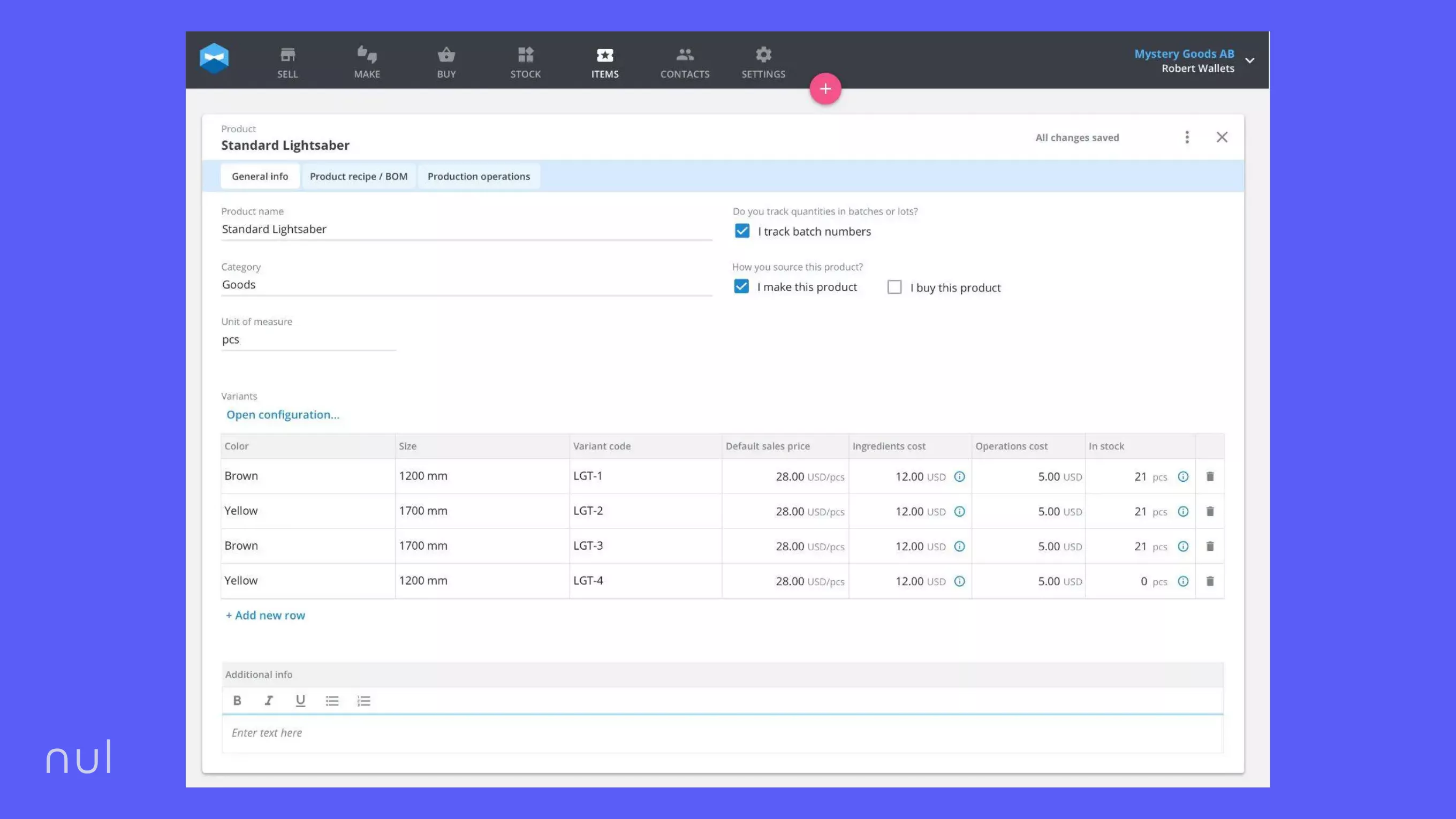

Katana

Katana MRP (Manufacturing Resource Planning) is a modern, cloud-based software solution that provides end-to-end visibility and control for manufacturing businesses. It serves apparel and footwear brands who run batch production or made-to-order (MTO) operations. Katana also integrates inventory, production scheduling, and sales management in real-time.

Highlights for batch production:

Batch Tracking: Track batches from the supplier, raw materials (fabric, trims, components) to the finished garment delivered to the customer, including expiry dates and recall history.

Real-Time Inventory and Master Planning: See raw materials and finished goods across locations, use warehouse features to monitor levels, and set reorder points and safety stock so critical fabrics or sizes don’t run out mid-season.

Shop Floor Control Integration: Features like a Shop Floor App to manage operations, assign tasks, track completion times, and update the batch status directly from the production floor.

Accurate Costing: Track material use via BOMs and monitor operation times to calculate batch costs accurately. Thus, brands can set precise prices and protect profit margins.

Omnichannel Fulfillment: Manage both B2B (wholesale) and D2C (direct-to-consumer) fulfillment so orders flow smoothly once a production batch is finished and ready to ship.

Limitation: Does not contain a native accounting module. Instead, it relies heavily on integrations with third-party accounting software (like QuickBooks or Xero) for financial reporting.

Best for: Small to mid-sized apparel, footwear, and textile brands that run frequent batch or make-to-order production.

Katana MRP is a modern, cloud-based software solution. (Source: Katana)

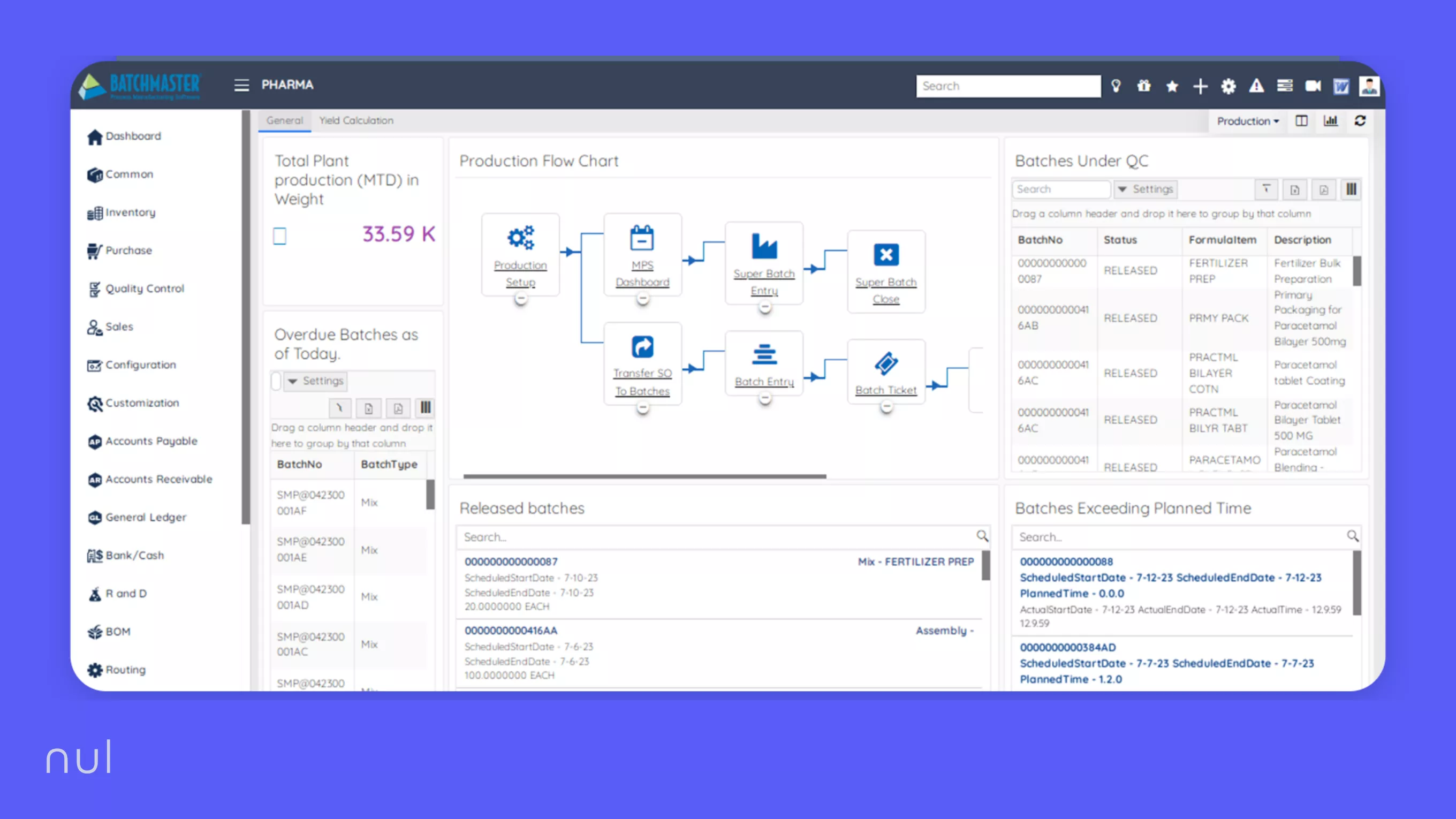

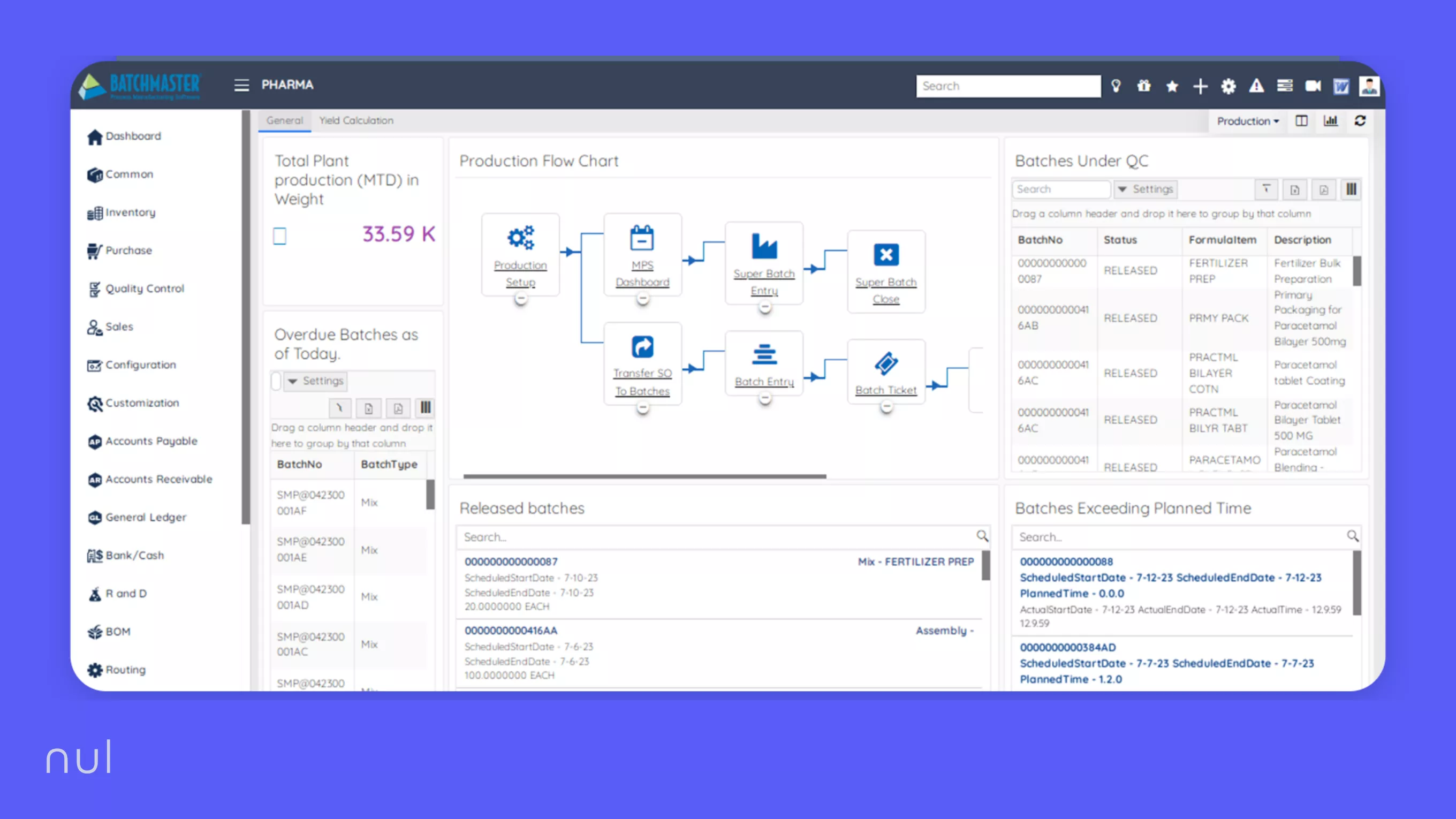

BatchMaster

BatchMaster is an ERP platform that previousely specializes in Process Manufacturing (industries based on formulas, recipes, and lots, like chemicals or food). But it now offers a dedicated, full-suite ERP solution tailored for the Fashion and Apparel Industry. It combines process-style batch control together with fashion-specific tools like colour–size matrices, advanced BOMs, and production planning & control (PPC).

Highlights for batch production:

Master Production Scheduling (MPS) & MRP: Forecast material needs, optimize production runs, and buy materials in time for the start of each batch.

Lot Traceability: Bi-direction features like Lot Traceability/Lot Recall to track from a fabric roll or dye batch to finished garments, and from a defective product back to the original lot and supplier.

Flexible Manufacturing Models: Handles both in-house and contract manufacturing, including job work management. Batches are planned and tracked even when production is outsourced to multiple partners.

Quality Assurance (QA) Integration: Check quality at various stages, ensuring batches meet specifications before moving to the next process or being shipped to customers.

Configurable Batch Production Engine: Size and schedule batch jobs, manage equipment and resource capacity, reserve inventory for specific batches, and auto-generate lot numbers with backflushing of inventory and labour.

Limitation: BatchMaster has a steep learning curve, complex to implement and maintain.

Best for: Apparel and fashion manufacturers that need an end-to-end ERP with strong process-style batch control plus fashion extras. Also, some parts of the system and document handling can feel old-fashioned.

BatchMaster is an ERP platform that previousely specializes in Process Manufacturing. (Source: BatchMaster)

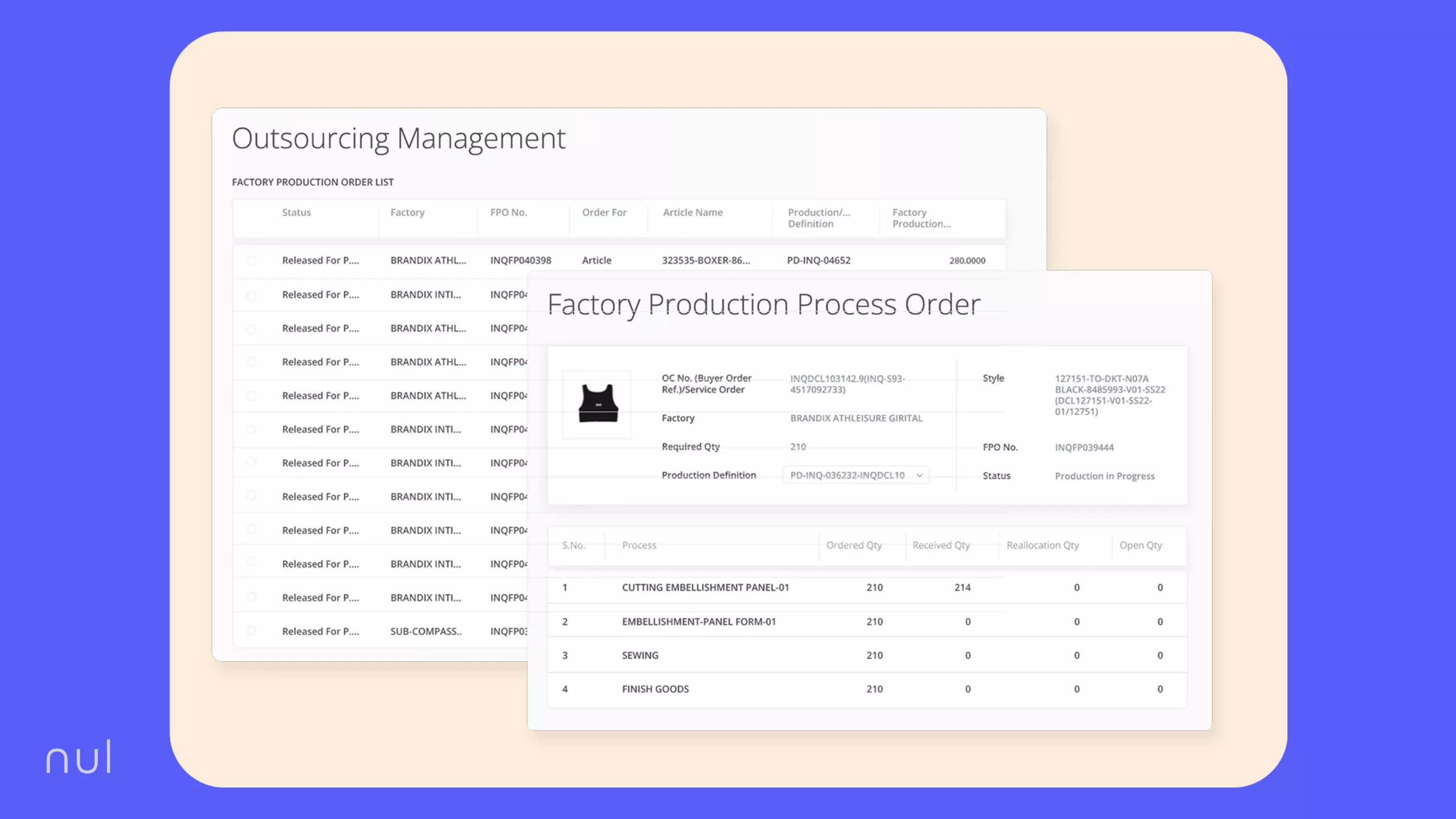

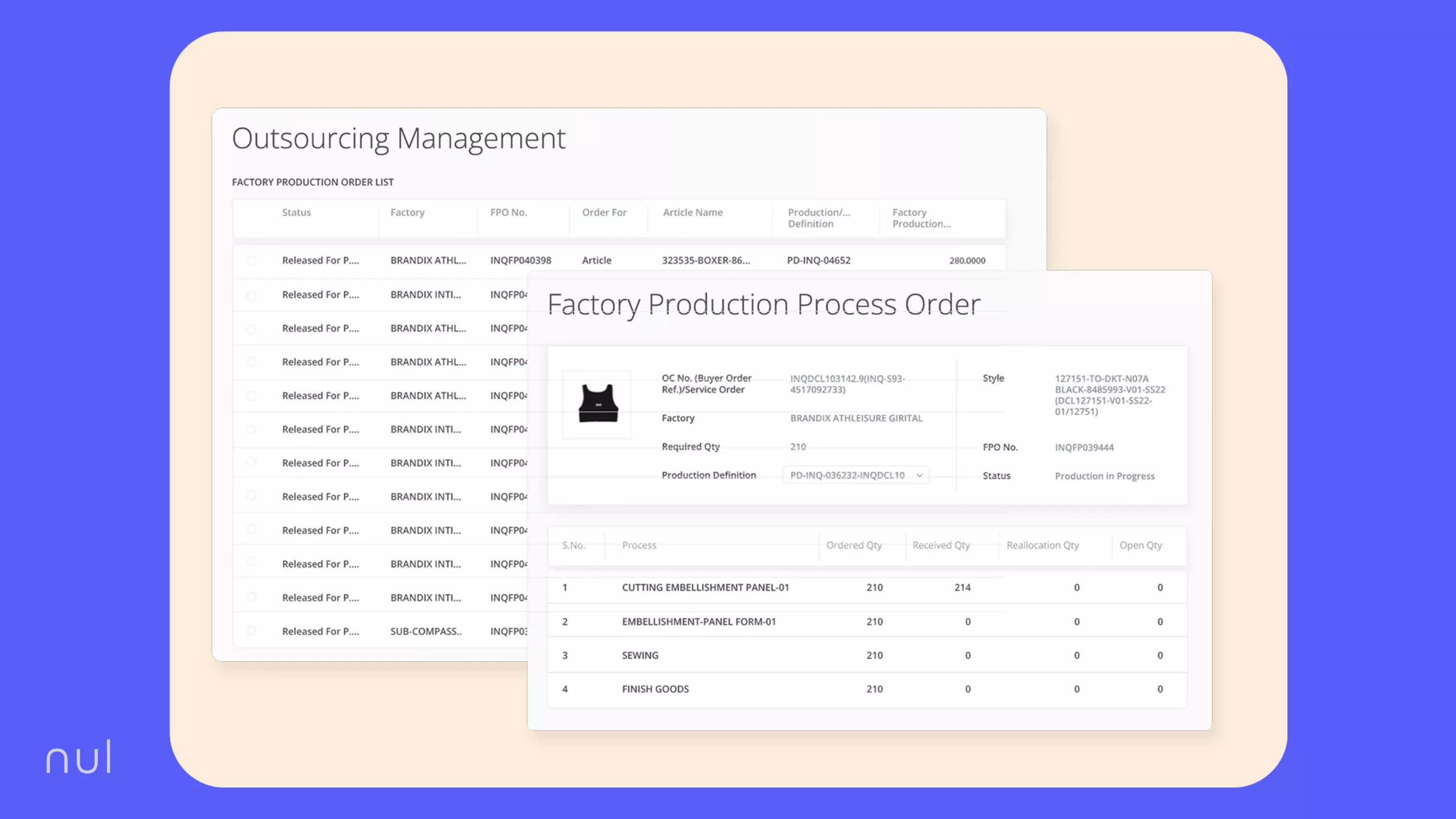

WFX Apparel ERP

WFX Apparel ERP is an end-to-end, cloud-based software suite 100% built for the fashion industry. It includes PLM (Product Lifecycle Management), ERP (Enterprise Resource Planning), MES (Manufacturing Execution System), and PPC (Production Planning and Control). Its main mission is to connect all aspects of the apparel business from initial concept and sourcing to factory production and financials.

Highlights for batch production:

End-to-End System: Remove data silos between departments like design and manufacturing, ensuring that batch production decisions are based on the latest financial and design data.

Production Planning & Control (PPC): Manage the factory floor, including PPC Software and MES (Smart Factory) tools to optimize factory performance, improve quality, and streamline production flow with real-time data collection.

Traceability and Quality Control (QC): Map the entire supply chain, support comprehensive quality checks at multiple levels, capturing, tracking, and managing defects or rejections in real time for specific batches.

Costing and Material Planning: Calculate costs and budgets, use intelligent Material Planning systems to track material consumption.

Collaboration Tools: Supplier Portal to streamline communication, tracking, and document approvals with manufacturing partners.

Limitation: Deep customization of core logic may be difficult or expensive, often requiring businesses to adapt their existing unique workflows to fit the software's structure.

Best for: Mid-to-large apparel and textile manufacturers that want a fashion-specific, cloud ERP with integrated PPC.

WFX Apparel ERP is an end-to-end, cloud-based software. (Source: WFX Apparel ERP)

Infor

Infor is a global, multi-industry ERP vendor that offers Infor CloudSuite Fashion, a dedicated solution for the apparel, footwear, accessories, and textile industries. With this tool, brands can manage the entire fashion value chain from concept to consumer. It integrates core enterprise functions with advanced PLM (Product Lifecycle Management), demand forecasting, and specialized supply chain network tools.

Highlights for batch production:

Integrated PLM and ERP: Connect design and development (PLM) directly with production and ERP. Technical specs, BOMs, materials, and compliance rules flow through to the factory, so batches move faster.

Multi-Attribute Management: Provide flexible attributes, detailed style specs, and controls for things like leather/hide characteristics or dye lots, keeping quality and color consistency across batches.

Optimized Supply Chain Inventory: Fashion-focused demand forecasting and WMS tools help plan bulk seasonal buys, balance stock across international facilities, and reduce excess inventory.

Global Collaboration and Traceability: Internal teams, suppliers, and partners work on the same data in real time to have clear visibility into outsourced batch production.

Limitation: Implementation can be complex and may require significant training and change management, which can be heavy for smaller brands with limited IT resources.

Best for: Large, global fashion enterprises, Tier 1 manufacturers, and luxury brands with complex supply chains, multi-national sourcing operations.

Infor is a global, multi-industry ERP vendor. (Source: Infor)

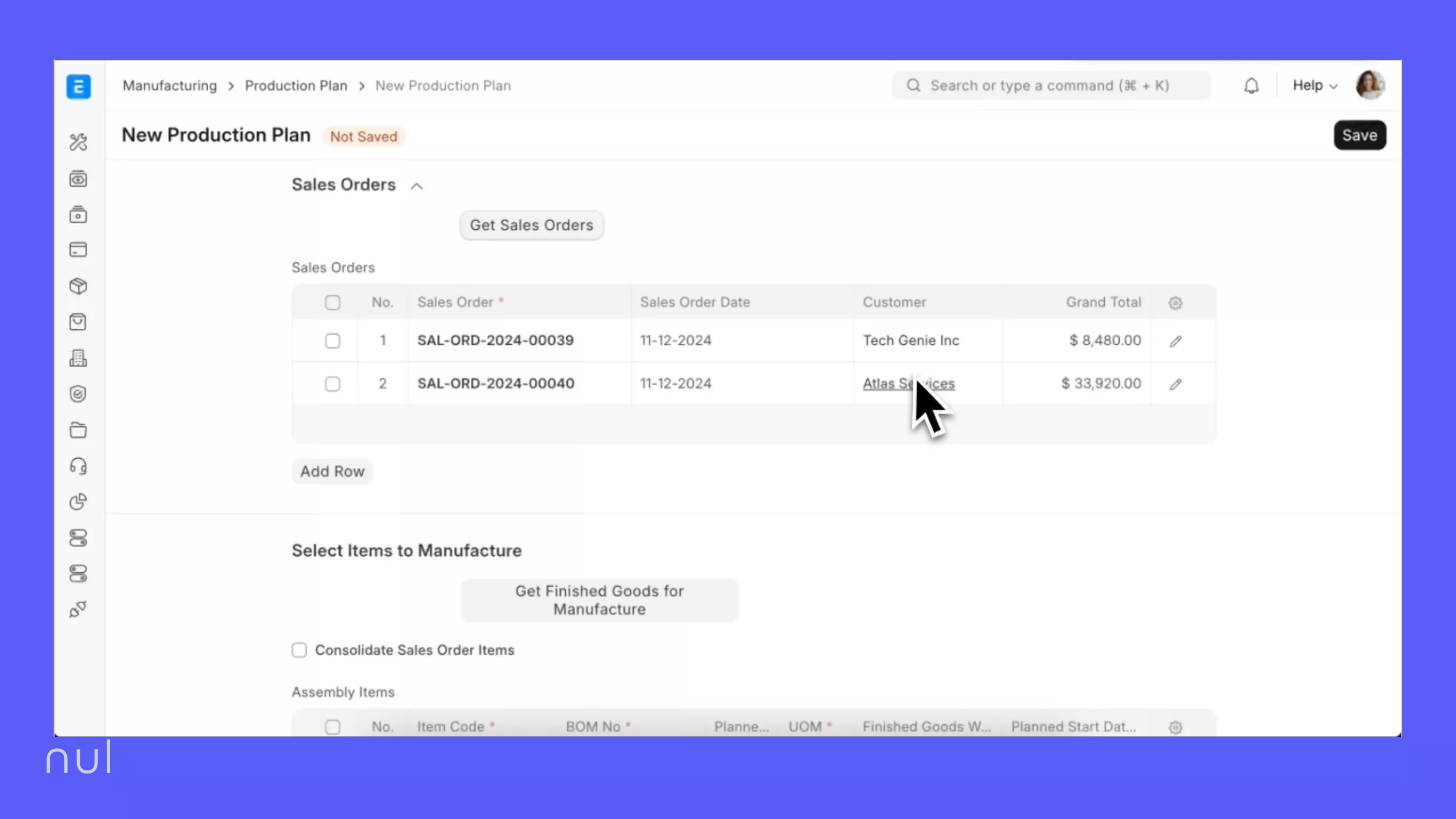

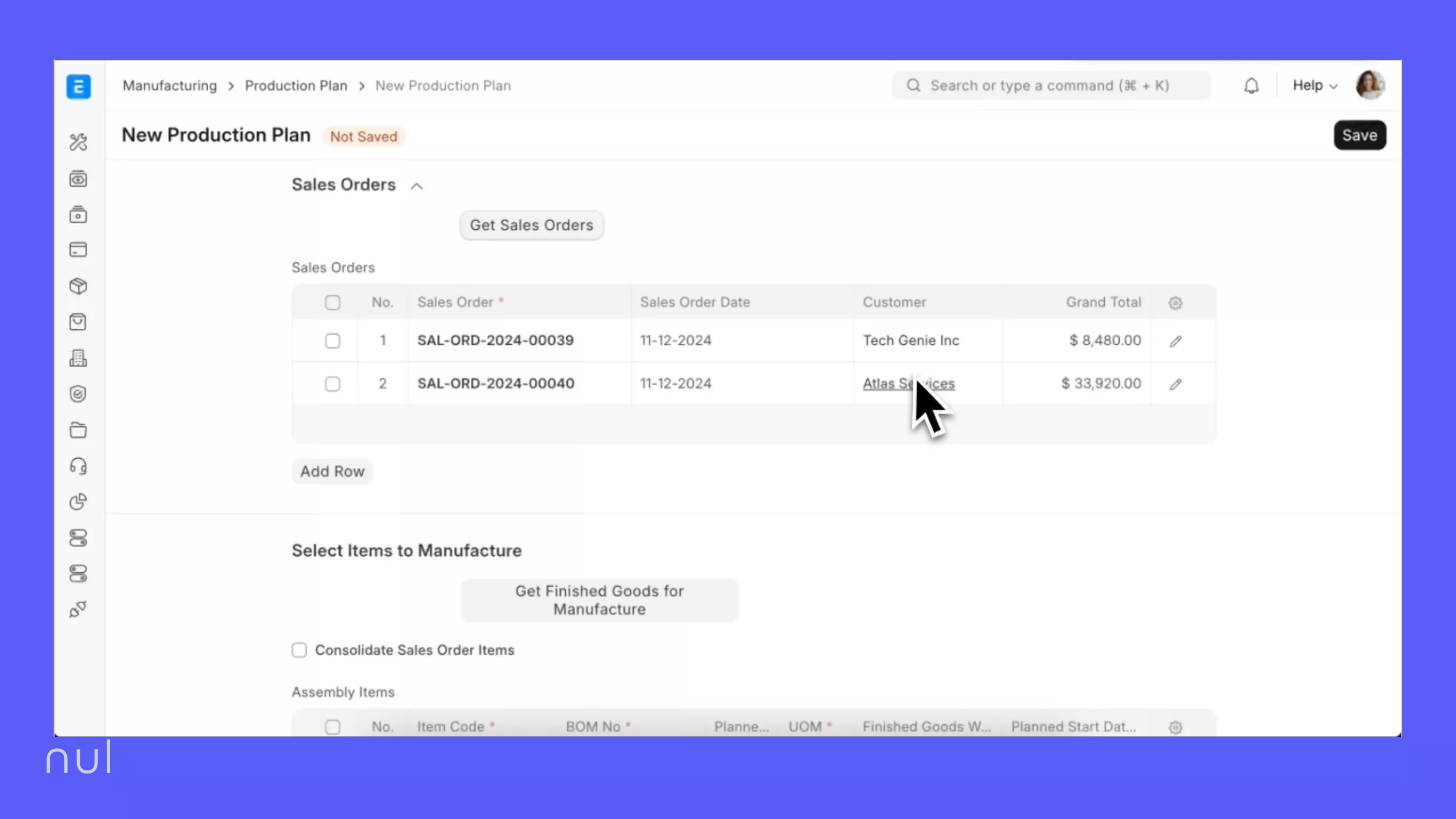

ERPNext

ERPNext is a open-source Enterprise Resource Planning (ERP) platform with a dedicated apparel manufacturing setup. It includes a suite of modules like Manufacturing, Inventory, CRM, Sales, and Accounting. Its open-source nature means it is highly customizable and backed by a large community, which a flexible and affordable alternative to proprietary systems.

Highlights for batch production:

Batched Inventory Control: Track product lots, manage manufacturing dates, and scan item barcodes for quick stock search and data-driven decisions.

Complex Variant Management: Use Item Variants and Item Templates to manage thousands of permutations in colors, sizes, and finishes, so defining and managing batch production orders is more accurate.

Shop Floor Management: Tools like Job Cards and Workstations to capture shop-floor activities and monitor progress

Subcontracting Management: Use the Subcontracting feature to supply raw materials to third-party distributors or factories and easily track the outsourced process of a batch.

Multiple Units of Measurement (UOM): Handle conversions between different units of measurement (e.g., meters of fabric vs. pieces of trim) to ensure accurate BOMs and batch material usage.

Limitation: Require in-house or partner developers for setup, implementation, maintenance, and complex troubleshooting.

Best for: Budget-conscious fashion brands and manufacturers seeking a powerful, integrated ERP solution without proprietary license fees

ERPNext is a open-source Enterprise Resource Planning (ERP) platform. (Source: ERPNext)

Conclusion

No single system is “best” for everyone. The safest way forward is to map your real workflows like demand planning, PPC, outsourcing, inventory, and fulfillment and pick the solution that strengthens those critical points first. Start with one platform that fits your current scale, and make sure it can grow with your production volume, number of locations, and level of supply chain complexity.

Article by

Nūl Content Team

An Experienced Research & Knowledge Team

The Nūl Content Team combines expertise in technology, fashion, and supply chain management to deliver clear, practical insights. Guided by Nūl’s mission to end overproduction, we create content that helps brands forecast demand more accurately, optimize inventory, and build sustainable operations. Every piece we publish is grounded in real-world experience, ensuring it’s both credible and actionable.

LinkedIn Profile

More From Blog

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

More From Blog

7 Best Batch Production Software Solutions for Fashion Brands

Dec 5, 2025

Nūl, ApparelMagic, Katana, BatchMaster, WFX Apparel ERP, Infor, ERPNext are the 7 best batch production software for fashion brands and manufacturers to consider.

These days, fashion brands who have to deal with various styles, colors, and sizes in their seasonal collections need to use batch production as their main workflow. To achieve a seamless and profitable process, brands need specialized software to plan batches, track materials in real-time, control production orders, and maintain visibility from cutting through finishing.

This blog will review top 7 reliable batch production software solutions to assist fashion teams find the best choice to operate their manufacturing processes.

Key Features of Batch Production Software for Fashion

Batch planning: Plan production in precise batches, grouping units by every variant.

Real-time material tracking: Show how much fabric, trims, and accessories are available or reserved for each batch.

Bill of Materials (BOM) management: Calculate costs, link raw materials to each style, and ensure factory teams use the correct components during production.

Production order management: Issue, schedule, and track production orders across multiple factories or suppliers.

Cutting and sewing workflow tracking: Follow each batch as it moves through cutting, sewing, finishing, and packing, giving teams visibility into work-in-progress.

Quality checks and approvals: Allow teams to review samples, track defects, and approve production before moving to the next stage.

Multi-location coordination: Sync batch updates to prevent duplicated production or missing stock across multiple factories or warehouses.

Integrated inventory updates: As batches progress, inventory is updated automatically like finished goods increase, raw materials decrease, and any variance is recorded.

Costing and margin visibility: See how material usage, labor, and batch sizes affect total cost and expected margin per style.

Supplier and factory collaboration: Brands can communicate requirements, track progress, and reduce errors with manufacturing partners via portals and shared workflows.

7 Best Batch Production Software Solutions

Software | Core Focus | Key Features | Best For |

|---|---|---|---|

Nūl | Agentic AI Planning & PPC |

| Fashion brands and manufacturers running many small–medium batches across multiple locations. |

ApparelMagic | Fashion-Native Cloud ERP/PLM |

| Small to larger fashion brands wanting one system for styles, inventory, production, and shipping. |

Katana MRP | Cloud Manufacturing Resource Planning |

| Small–mid apparel/footwear brands doing batch or MTO with omnichannel sales. |

BatchMaster | Process-Centric ERP |

| Apparel manufacturers needing full ERP plus strong batch, lot, and PPC control. |

WFX Apparel ERP | Unified Global Supply Chain Suite |

| Mid–large manufacturers with multi-factory / subcontracting setups |

Infor | Global Enterprise ERP |

| Medium–large global brands needing an integrated enterprise stack. |

ERPNext | Open-Source Full-Suite ERP |

| Small–mid apparel/textile manufacturers wanting flexible, low-license-cost ERP. |

Nūl

Nūl is an Agentic AI platform for inventory optimization and demand planning, with the aim to achieve zero-waste fashion by preventing overproduction. Its Production Planning and Control (PPC) module links AI-driven forecasting with the factory floor for efficient and material-accurate batch manufacturing. In fact, every batch is planned with the right quantities, timing, and materials, so production can maintains healthy inventory levels.

Highlights for batch production:

Production Requests list: with filters by location, type, PIC, and status, so you can quickly isolate, for example, all samples at one factory or all batches committed to cut this week.

SKU-Level Control: Allow production planning for specific line items, managing the mix of Color, Size, and even Customization Notes within a single batch work order.

Real-Time Material Readiness (MRP): Instantly check material inventory against the BOM (Bill of Materials) for the batch. It has clear labels like Full Stock, Partial Shortage, or Full Shortage, detailing the exact material and the precise shortfall.

Traceability and Status: Use an auditable Order Timeline that records every status change (e.g., Committed to Cut, In-production) and tracks the overall Batch Status for quick oversight.

Output tagging for fulfilment: Tags like Full, Partial, and Reserved for finished SKUs, helping teams decide how batch output should be allocated to orders.

Limitation: Nūl is not a complete manufacturing platform or full MES that handles the moment-to-moment management and optimization of the physical production process itself.

Best for: Fashion brands and manufacturers running many small to medium batches (MTO, samples, custom orders) across multiple locations that need SKU-level visibility into status and materials, especially when production is outsourced.

Nūl is an Agentic AI platform with batch production feature. (Source: Nūl)

ApparelMagic

ApparelMagic is a cloud-based ERP (Enterprise Resource Planning) platform built for the apparel, accessories, and fashion industries. As an all-in-one solution, it integrates Product Lifecycle Management (PLM), Manufacturing, Inventory Management, Wholesale, and Accounting into a single system.

Highlights for batch production:

Integrated PLM to Production: Link Tech Packs, Bills of Materials (BOMs), and detailed product specifications directly to manufacturing orders. The factory teams can receive accurate instructions and use the correct raw materials for every batch.

WIP and Multi-Stage Tracking: Manage Work-In-Progress (WIP) by tracking production through defined multi-stage manufacturing processes. Planning teams have real-time visibility into the status and location of a batch throughout cutting, sewing, and finishing.

Advanced Fulfillment: Support efficient logistics with Batch Picking (picking multiple sales orders simultaneously) and flexible Allocation Methods, speeding up the order fulfillment process once a production batch is completed and received into inventory.

Robust Size/Color Matrix: Provide support for managing complex product variants, ensuring inventory accuracy and simplifying the planning of units per size run in any batch.

Limitation: May not offer the same level of deep, code-level customization or complex vertical integration for huge global corporations

Best for: Mid-sized and growing fashion brands (both wholesale and DTC) that require an affordable, integrated ERP solution to handle operations from design conception to final delivery.

ApparelMagic is a cloud-based ERP platform. (Source: ApparelMagic)

Katana

Katana MRP (Manufacturing Resource Planning) is a modern, cloud-based software solution that provides end-to-end visibility and control for manufacturing businesses. It serves apparel and footwear brands who run batch production or made-to-order (MTO) operations. Katana also integrates inventory, production scheduling, and sales management in real-time.

Highlights for batch production:

Batch Tracking: Track batches from the supplier, raw materials (fabric, trims, components) to the finished garment delivered to the customer, including expiry dates and recall history.

Real-Time Inventory and Master Planning: See raw materials and finished goods across locations, use warehouse features to monitor levels, and set reorder points and safety stock so critical fabrics or sizes don’t run out mid-season.

Shop Floor Control Integration: Features like a Shop Floor App to manage operations, assign tasks, track completion times, and update the batch status directly from the production floor.

Accurate Costing: Track material use via BOMs and monitor operation times to calculate batch costs accurately. Thus, brands can set precise prices and protect profit margins.

Omnichannel Fulfillment: Manage both B2B (wholesale) and D2C (direct-to-consumer) fulfillment so orders flow smoothly once a production batch is finished and ready to ship.

Limitation: Does not contain a native accounting module. Instead, it relies heavily on integrations with third-party accounting software (like QuickBooks or Xero) for financial reporting.

Best for: Small to mid-sized apparel, footwear, and textile brands that run frequent batch or make-to-order production.

Katana MRP is a modern, cloud-based software solution. (Source: Katana)

BatchMaster

BatchMaster is an ERP platform that previousely specializes in Process Manufacturing (industries based on formulas, recipes, and lots, like chemicals or food). But it now offers a dedicated, full-suite ERP solution tailored for the Fashion and Apparel Industry. It combines process-style batch control together with fashion-specific tools like colour–size matrices, advanced BOMs, and production planning & control (PPC).

Highlights for batch production:

Master Production Scheduling (MPS) & MRP: Forecast material needs, optimize production runs, and buy materials in time for the start of each batch.

Lot Traceability: Bi-direction features like Lot Traceability/Lot Recall to track from a fabric roll or dye batch to finished garments, and from a defective product back to the original lot and supplier.

Flexible Manufacturing Models: Handles both in-house and contract manufacturing, including job work management. Batches are planned and tracked even when production is outsourced to multiple partners.

Quality Assurance (QA) Integration: Check quality at various stages, ensuring batches meet specifications before moving to the next process or being shipped to customers.

Configurable Batch Production Engine: Size and schedule batch jobs, manage equipment and resource capacity, reserve inventory for specific batches, and auto-generate lot numbers with backflushing of inventory and labour.

Limitation: BatchMaster has a steep learning curve, complex to implement and maintain.

Best for: Apparel and fashion manufacturers that need an end-to-end ERP with strong process-style batch control plus fashion extras. Also, some parts of the system and document handling can feel old-fashioned.

BatchMaster is an ERP platform that previousely specializes in Process Manufacturing. (Source: BatchMaster)

WFX Apparel ERP

WFX Apparel ERP is an end-to-end, cloud-based software suite 100% built for the fashion industry. It includes PLM (Product Lifecycle Management), ERP (Enterprise Resource Planning), MES (Manufacturing Execution System), and PPC (Production Planning and Control). Its main mission is to connect all aspects of the apparel business from initial concept and sourcing to factory production and financials.

Highlights for batch production:

End-to-End System: Remove data silos between departments like design and manufacturing, ensuring that batch production decisions are based on the latest financial and design data.

Production Planning & Control (PPC): Manage the factory floor, including PPC Software and MES (Smart Factory) tools to optimize factory performance, improve quality, and streamline production flow with real-time data collection.

Traceability and Quality Control (QC): Map the entire supply chain, support comprehensive quality checks at multiple levels, capturing, tracking, and managing defects or rejections in real time for specific batches.

Costing and Material Planning: Calculate costs and budgets, use intelligent Material Planning systems to track material consumption.

Collaboration Tools: Supplier Portal to streamline communication, tracking, and document approvals with manufacturing partners.

Limitation: Deep customization of core logic may be difficult or expensive, often requiring businesses to adapt their existing unique workflows to fit the software's structure.

Best for: Mid-to-large apparel and textile manufacturers that want a fashion-specific, cloud ERP with integrated PPC.

WFX Apparel ERP is an end-to-end, cloud-based software. (Source: WFX Apparel ERP)

Infor

Infor is a global, multi-industry ERP vendor that offers Infor CloudSuite Fashion, a dedicated solution for the apparel, footwear, accessories, and textile industries. With this tool, brands can manage the entire fashion value chain from concept to consumer. It integrates core enterprise functions with advanced PLM (Product Lifecycle Management), demand forecasting, and specialized supply chain network tools.

Highlights for batch production:

Integrated PLM and ERP: Connect design and development (PLM) directly with production and ERP. Technical specs, BOMs, materials, and compliance rules flow through to the factory, so batches move faster.

Multi-Attribute Management: Provide flexible attributes, detailed style specs, and controls for things like leather/hide characteristics or dye lots, keeping quality and color consistency across batches.

Optimized Supply Chain Inventory: Fashion-focused demand forecasting and WMS tools help plan bulk seasonal buys, balance stock across international facilities, and reduce excess inventory.

Global Collaboration and Traceability: Internal teams, suppliers, and partners work on the same data in real time to have clear visibility into outsourced batch production.

Limitation: Implementation can be complex and may require significant training and change management, which can be heavy for smaller brands with limited IT resources.

Best for: Large, global fashion enterprises, Tier 1 manufacturers, and luxury brands with complex supply chains, multi-national sourcing operations.

Infor is a global, multi-industry ERP vendor. (Source: Infor)

ERPNext

ERPNext is a open-source Enterprise Resource Planning (ERP) platform with a dedicated apparel manufacturing setup. It includes a suite of modules like Manufacturing, Inventory, CRM, Sales, and Accounting. Its open-source nature means it is highly customizable and backed by a large community, which a flexible and affordable alternative to proprietary systems.

Highlights for batch production:

Batched Inventory Control: Track product lots, manage manufacturing dates, and scan item barcodes for quick stock search and data-driven decisions.

Complex Variant Management: Use Item Variants and Item Templates to manage thousands of permutations in colors, sizes, and finishes, so defining and managing batch production orders is more accurate.

Shop Floor Management: Tools like Job Cards and Workstations to capture shop-floor activities and monitor progress

Subcontracting Management: Use the Subcontracting feature to supply raw materials to third-party distributors or factories and easily track the outsourced process of a batch.

Multiple Units of Measurement (UOM): Handle conversions between different units of measurement (e.g., meters of fabric vs. pieces of trim) to ensure accurate BOMs and batch material usage.

Limitation: Require in-house or partner developers for setup, implementation, maintenance, and complex troubleshooting.

Best for: Budget-conscious fashion brands and manufacturers seeking a powerful, integrated ERP solution without proprietary license fees

ERPNext is a open-source Enterprise Resource Planning (ERP) platform. (Source: ERPNext)

Conclusion

No single system is “best” for everyone. The safest way forward is to map your real workflows like demand planning, PPC, outsourcing, inventory, and fulfillment and pick the solution that strengthens those critical points first. Start with one platform that fits your current scale, and make sure it can grow with your production volume, number of locations, and level of supply chain complexity.

Article by

Nūl Content Team

An Experienced Research & Knowledge Team

An Experienced Research & Knowledge Team

The Nūl Content Team combines expertise in technology, fashion, and supply chain management to deliver clear, practical insights. Guided by Nūl’s mission to end overproduction, we create content that helps brands forecast demand more accurately, optimize inventory, and build sustainable operations. Every piece we publish is grounded in real-world experience, ensuring it’s both credible and actionable.

LinkedIn Profile