What’s Raw Material Management? Process, Metrics, Best Practices

Oct 22, 2025

Raw material management involves forecasting, sourcing, storing, and tracking production inputs to keep materials flowing efficiently and minimize waste or delays.

Behind every finished product lies an intricate web of materials — cotton yarns, zippers, buttons, dyes, packaging, and more. Managing these inputs efficiently is what determines whether a fashion brand runs smoothly or struggles with delays, stockouts, and wasted capital.

Raw material management sits at the foundation of a brand’s supply chain. It ensures that every roll of fabric, every spool of thread, and every trim is ordered, stored, and issued efficiently — aligning production schedules, quality targets, and sustainability goals.

This guide breaks down everything you need to know: what raw material management means, why it’s critical, how it works, and how intelligent platforms help brands manage it seamlessly.

What is Raw Material Management?

Raw material management is the process of forecasting, procuring, storing, and tracking the basic inputs required for production. It ensures that materials move efficiently through the supply chain — from procurement to production to finished goods — without disruptions or waste.

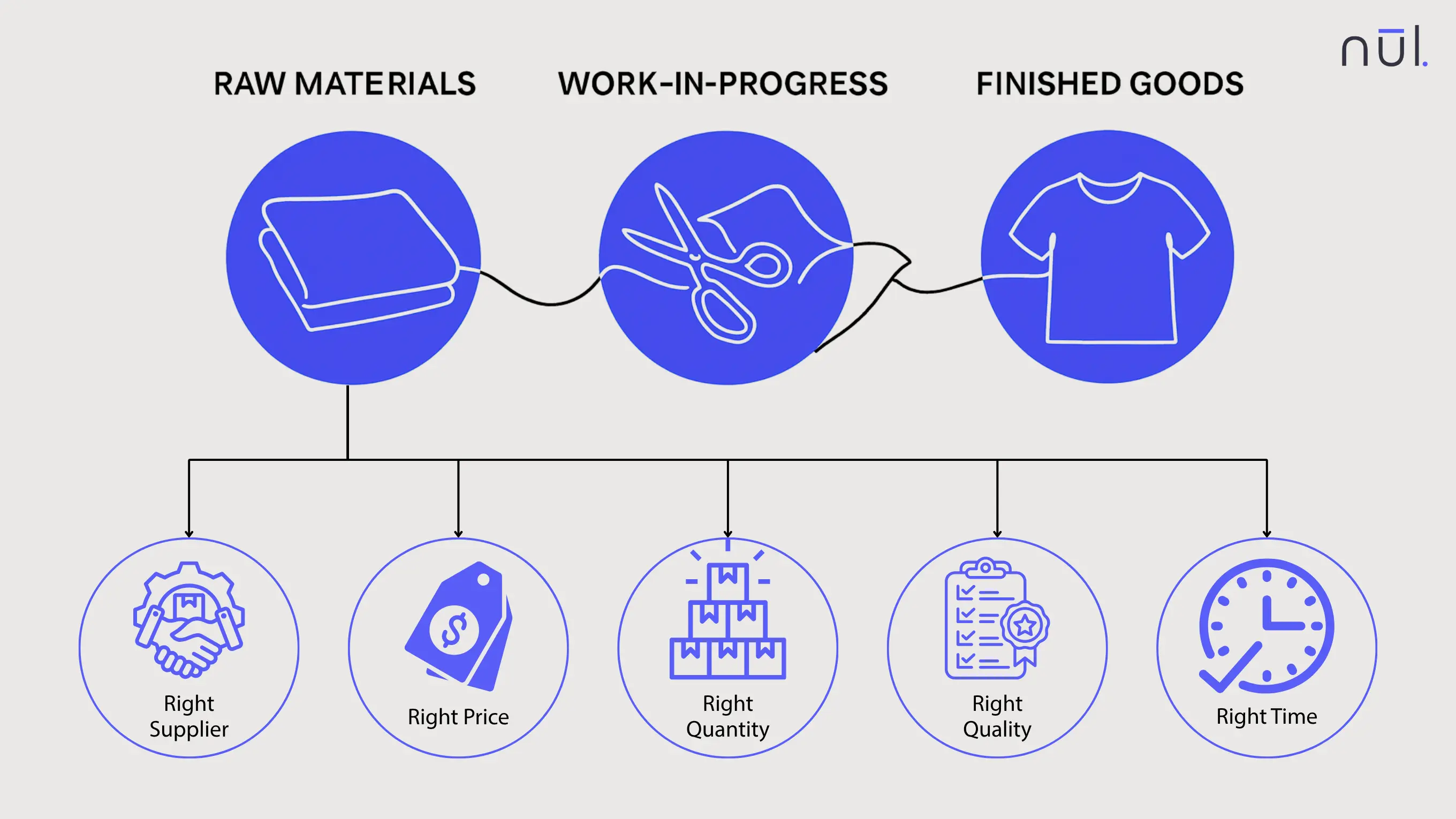

It typically spans three inventory stages:

Raw materials: Base components like fabrics, threads, trims, and packaging.

Work-in-progress (WIP): Items partially assembled, e.g., cut panels or dyed fabrics.

Finished goods: Completed products ready for distribution or sale.

The “5 Rs” of Material Management:

The goal of any material manager is to achieve the 5 Rs:

Right supplier – Reliable, compliant, and consistent in quality.

Right price – Competitive cost aligned with budget and market trends.

Right quantity – Enough to meet demand without overstocking.

Right quality – Meets production and customer standards.

Right time – Delivered when needed to prevent production delays.

Balancing these five ensures operational efficiency and cost control.

What is Raw Material Management?

Direct vs. Indirect Raw Materials

To manage inventory effectively, it’s crucial to distinguish between direct and indirect raw materials.

Direct materials: Physically form part of the finished product (e.g., cotton for a t-shirt, leather for a bag). These are the inputs that define the product’s structure, quality, and appearance.

Indirect materials: Support production but don’t become part of the final product (e.g., cleaning agents, maintenance tools, packaging materials). They’re essential for operations but are treated differently in accounting and cost control.

Tracking direct and indirect materials separately allows companies to measure true production costs, allocate budgets accurately, and identify inefficiencies within the supply chain. Direct materials directly affect profit margins, while indirect materials influence overhead and process efficiency.

Example: In a fashion brand, fabrics and zippers are direct materials, while thread lubricants or packing tapes are indirect. If fabrics are delayed, production halts. If packaging runs out, shipments stall. Both need visibility — but they’re managed differently.

Why is Raw Material Management Important?

Ensures Production Continuity: Keeps the production line running without costly interruptions.

Maintains Product Quality: Reliable materials ensure consistency across collections.

Controls Operational Costs: Prevents overbuying and reduces carrying costs.

Supports Sustainability: Reduces excess stock, waste, and carbon footprint.

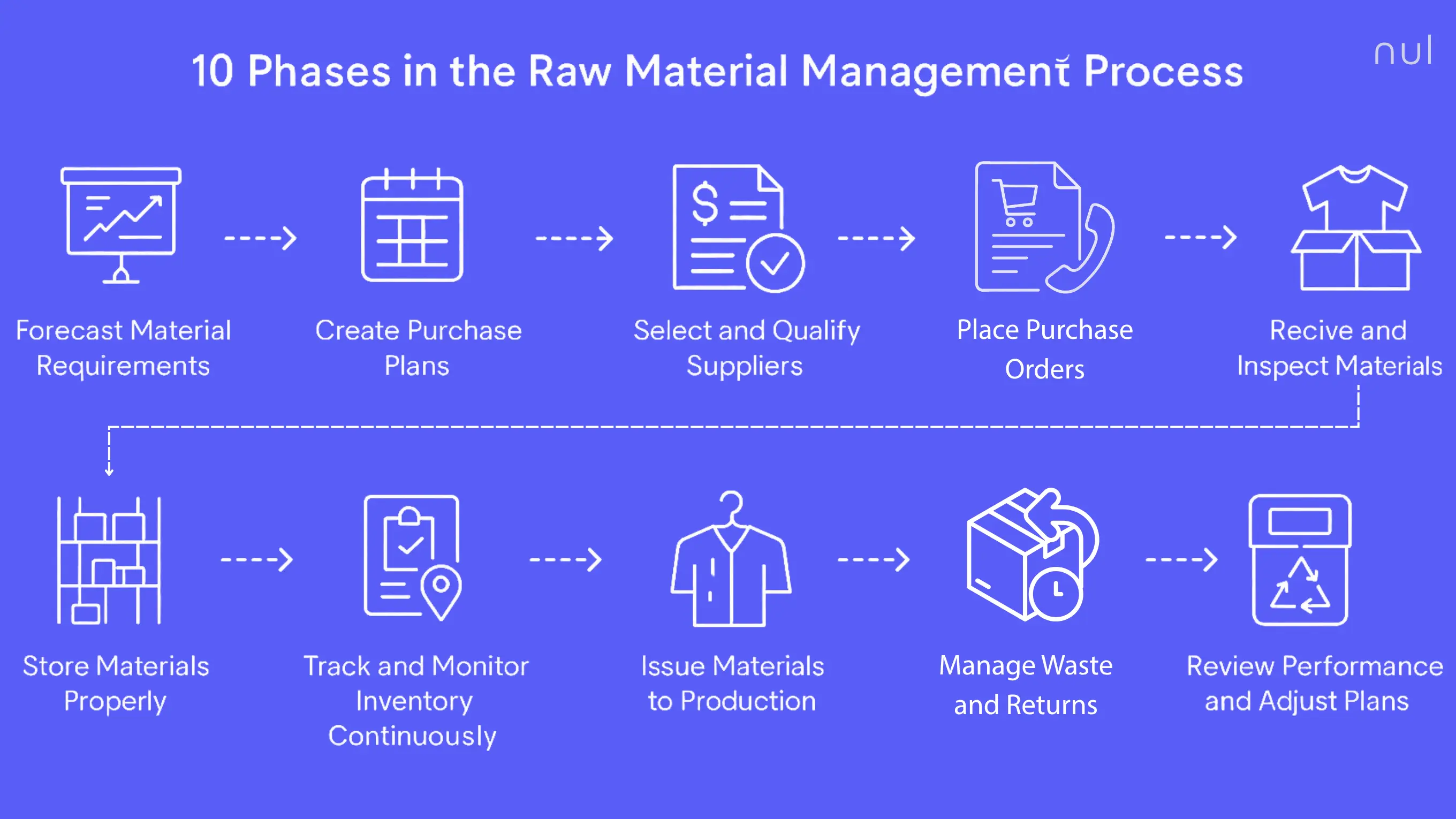

10 Phases in the Raw Material Management Process

Forecast Material Requirements

Estimate future demand using past consumption data, BOMs (Bill of Materials), and yield loss.

Factor in seasonality, new designs, and regional demand to prevent understocking or waste.

Create Purchase Plans

Translate forecasts into procurement schedules — monthly or quarterly.

Include supplier lead times, budget caps, and safety stock buffers for disruptions.

Select and Qualify Suppliers

Evaluate vendors based on:

Pricing consistency

Delivery reliability

Quality control track record

Maintain a supplier scorecard to monitor performance and mitigate risk.

Place Purchase Orders

Generate precise purchase orders (POs) with:

Material codes

Descriptions

Quantities

Delivery dates

Payment terms

Integrate with ERP systems for automatic tracking and approval workflows.

Receive and Inspect Materials

On delivery, verify quality and quantity against PO specs.

Use sampling or 100% inspection depending on material criticality.

Record deviations immediately, quarantine defective stock, and update digital records.

Store Materials Properly

Implement organized warehouse layouts with clear zoning by material type, batch, or usage frequency.

Follow material-specific storage conditions (humidity, temperature, stacking).

Apply FIFO (First In, First Out), LIFO, or FEFO (First Expiry, First Out) rules to manage shelf life.

Track and Monitor Inventory Continuously

Use digital tracking (barcodes, RFID, or IoT sensors) to record stock movements.

Track available, committed, and on-order quantities across locations.

Identify slow-moving, obsolete, or at-risk materials early to reduce waste.

Issue Materials to Production

Distribute materials to production lines based on work orders or batch schedules.

Automate consumption recording via backflush accounting to reduce manual errors.

Ensure traceability across batches and product types for better quality assurance and reporting.

Manage Waste and Returns

Separate reusable, scrap, and rejected materials immediately after production.

Track waste percentages by batch or department to identify efficiency gaps.

Return reusable materials to inventory or suppliers, and recycle where possible to support sustainability targets.

. Review Performance and Adjust Plans

Regularly analyze supplier reliability, cost trends, and inventory accuracy.

Review KPIs such as material turnover, order fulfillment rate, and waste ratio.

Use insights to refine forecasting, adjust reorder points, and strengthen sourcing strategies for future production cycles.

Raw Material Management Process

Common Challenges in Raw Material Management

Forecasting errors leading to stockouts or overstock

Long supplier lead times that delay production

Storage constraints or poor layout utilization

Data silos between purchasing, production, and finance

Lack of visibility into on-order vs. available stock

Best Practices to Improve Raw Material Management

Adopt AI-Based Demand Forecasting: Use AI or predictive analytics to forecast material requirements based on real-time sales, production data, and seasonal trends. This reduces reliance on guesswork, improves planning accuracy, and minimizes stock imbalances — a critical advantage for fast-moving industries like fashion.

Standardize Supplier Evaluation: Develop unified supplier scorecards that rate vendors on cost, lead time, quality, and compliance. Digital contracts and automated evaluations improve transparency and help maintain a reliable supplier base.

Set Reorder Points and Safety Stock Levels: Automate triggers for replenishment. These parameters ensure timely replenishment, protect against unexpected demand spikes, and maintain a stable production rhythm.

Use FIFO or FEFO for Seasonal Goods: This practice prevents material expiration, supports efficient rotation, and reduces waste — especially for color-sensitive fabrics, dyes, or packaging.

Track KPIs: Focus on material turnover rate, carrying cost, and stock accuracy. Tracking these KPIs allows continuous improvement and gives managers visibility into bottlenecks or inefficiencies.

Foster Cross-Functional Communication: Connect procurement, warehouse, and production teams. Integrated communication platforms and shared dashboards eliminate data silos and ensure everyone operates from the same, updated information.

Digitize Material Tracking: Implement ERP/MRP tools to centralize visibility. Digital tracking ensures real-time visibility into stock movement, on-order quantities, and usage trends .

Monitor Inventory Health with Dashboards: Visualize stock risk, reorder alerts, and waste ratios by using cloud-based dashboards. Some systems also provide “inventory health” indicators that help teams prioritize actions, cut waste, and maintain a steady production flow.

>> Explore digital solutions in raw material and inventory management:

Top 10 AI Fashion Inventory Management Software Solutions

Top 7 AI-Powered Demand Forecasting Tools for Fashion

Raw Material Management on the Nūl Platform

At Nūl, raw material management isn’t just a spreadsheet — it’s a real-time intelligence layer for fashion production.

Core Features:

Automated demand forecasting for material needs

Integrated supplier tracking and performance scoring

Inventory health dashboards across locations

Smart reorder alerts and consumption tracking

Metrics Tracked:

Material turnover rate

Stock accuracy (%)

Supplier lead time

Material waste percentage

Reorder and fill rates

Tracking Methods:

API syncs with Shopify, ERP, or production software

AI-driven demand modeling

Real-time PO and stock reconciliation

Value to Users:

Operational efficiency: No more stockouts or over-ordering.

Sustainability: Reduced deadstock and waste.

Visibility: Unified data from procurement to production.

Scalability: Works for small brands or multi-factory enterprises.

>> Explore more raw material management solutions:

Top 8 Best Raw Material Inventory Management Software

Top 7 Best Inventory Management Software with Bill of Materials

Conclusion

Raw material management is more than logistics — it’s the heart of production planning and sustainability. When materials flow smoothly, so does everything else: forecasting, production, and profitability.

By combining accurate forecasting, disciplined procurement, and AI-powered visibility, brands can unlock operational resilience — transforming their supply chains from reactive to predictive.

Article by

Nūl Content Team

An Experienced Research & Knowledge Team

The Nūl Content Team combines expertise in technology, fashion, and supply chain management to deliver clear, practical insights. Guided by Nūl’s mission to end overproduction, we create content that helps brands forecast demand more accurately, optimize inventory, and build sustainable operations. Every piece we publish is grounded in real-world experience, ensuring it’s both credible and actionable.

LinkedIn Profile

More From Blog

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

More From Blog

What’s Raw Material Management? Process, Metrics, Best Practices

Oct 22, 2025

Raw material management involves forecasting, sourcing, storing, and tracking production inputs to keep materials flowing efficiently and minimize waste or delays.

Behind every finished product lies an intricate web of materials — cotton yarns, zippers, buttons, dyes, packaging, and more. Managing these inputs efficiently is what determines whether a fashion brand runs smoothly or struggles with delays, stockouts, and wasted capital.

Raw material management sits at the foundation of a brand’s supply chain. It ensures that every roll of fabric, every spool of thread, and every trim is ordered, stored, and issued efficiently — aligning production schedules, quality targets, and sustainability goals.

This guide breaks down everything you need to know: what raw material management means, why it’s critical, how it works, and how intelligent platforms help brands manage it seamlessly.

What is Raw Material Management?

Raw material management is the process of forecasting, procuring, storing, and tracking the basic inputs required for production. It ensures that materials move efficiently through the supply chain — from procurement to production to finished goods — without disruptions or waste.

It typically spans three inventory stages:

Raw materials: Base components like fabrics, threads, trims, and packaging.

Work-in-progress (WIP): Items partially assembled, e.g., cut panels or dyed fabrics.

Finished goods: Completed products ready for distribution or sale.

The “5 Rs” of Material Management:

The goal of any material manager is to achieve the 5 Rs:

Right supplier – Reliable, compliant, and consistent in quality.

Right price – Competitive cost aligned with budget and market trends.

Right quantity – Enough to meet demand without overstocking.

Right quality – Meets production and customer standards.

Right time – Delivered when needed to prevent production delays.

Balancing these five ensures operational efficiency and cost control.

What is Raw Material Management?

Direct vs. Indirect Raw Materials

To manage inventory effectively, it’s crucial to distinguish between direct and indirect raw materials.

Direct materials: Physically form part of the finished product (e.g., cotton for a t-shirt, leather for a bag). These are the inputs that define the product’s structure, quality, and appearance.

Indirect materials: Support production but don’t become part of the final product (e.g., cleaning agents, maintenance tools, packaging materials). They’re essential for operations but are treated differently in accounting and cost control.

Tracking direct and indirect materials separately allows companies to measure true production costs, allocate budgets accurately, and identify inefficiencies within the supply chain. Direct materials directly affect profit margins, while indirect materials influence overhead and process efficiency.

Example: In a fashion brand, fabrics and zippers are direct materials, while thread lubricants or packing tapes are indirect. If fabrics are delayed, production halts. If packaging runs out, shipments stall. Both need visibility — but they’re managed differently.

Why is Raw Material Management Important?

Ensures Production Continuity: Keeps the production line running without costly interruptions.

Maintains Product Quality: Reliable materials ensure consistency across collections.

Controls Operational Costs: Prevents overbuying and reduces carrying costs.

Supports Sustainability: Reduces excess stock, waste, and carbon footprint.

10 Phases in the Raw Material Management Process

Forecast Material Requirements

Estimate future demand using past consumption data, BOMs (Bill of Materials), and yield loss.

Factor in seasonality, new designs, and regional demand to prevent understocking or waste.

Create Purchase Plans

Translate forecasts into procurement schedules — monthly or quarterly.

Include supplier lead times, budget caps, and safety stock buffers for disruptions.

Select and Qualify Suppliers

Evaluate vendors based on:

Pricing consistency

Delivery reliability

Quality control track record

Maintain a supplier scorecard to monitor performance and mitigate risk.

Place Purchase Orders

Generate precise purchase orders (POs) with:

Material codes

Descriptions

Quantities

Delivery dates

Payment terms

Integrate with ERP systems for automatic tracking and approval workflows.

Receive and Inspect Materials

On delivery, verify quality and quantity against PO specs.

Use sampling or 100% inspection depending on material criticality.

Record deviations immediately, quarantine defective stock, and update digital records.

Store Materials Properly

Implement organized warehouse layouts with clear zoning by material type, batch, or usage frequency.

Follow material-specific storage conditions (humidity, temperature, stacking).

Apply FIFO (First In, First Out), LIFO, or FEFO (First Expiry, First Out) rules to manage shelf life.

Track and Monitor Inventory Continuously

Use digital tracking (barcodes, RFID, or IoT sensors) to record stock movements.

Track available, committed, and on-order quantities across locations.

Identify slow-moving, obsolete, or at-risk materials early to reduce waste.

Issue Materials to Production

Distribute materials to production lines based on work orders or batch schedules.

Automate consumption recording via backflush accounting to reduce manual errors.

Ensure traceability across batches and product types for better quality assurance and reporting.

Manage Waste and Returns

Separate reusable, scrap, and rejected materials immediately after production.

Track waste percentages by batch or department to identify efficiency gaps.

Return reusable materials to inventory or suppliers, and recycle where possible to support sustainability targets.

. Review Performance and Adjust Plans

Regularly analyze supplier reliability, cost trends, and inventory accuracy.

Review KPIs such as material turnover, order fulfillment rate, and waste ratio.

Use insights to refine forecasting, adjust reorder points, and strengthen sourcing strategies for future production cycles.

Raw Material Management Process

Common Challenges in Raw Material Management

Forecasting errors leading to stockouts or overstock

Long supplier lead times that delay production

Storage constraints or poor layout utilization

Data silos between purchasing, production, and finance

Lack of visibility into on-order vs. available stock

Best Practices to Improve Raw Material Management

Adopt AI-Based Demand Forecasting: Use AI or predictive analytics to forecast material requirements based on real-time sales, production data, and seasonal trends. This reduces reliance on guesswork, improves planning accuracy, and minimizes stock imbalances — a critical advantage for fast-moving industries like fashion.

Standardize Supplier Evaluation: Develop unified supplier scorecards that rate vendors on cost, lead time, quality, and compliance. Digital contracts and automated evaluations improve transparency and help maintain a reliable supplier base.

Set Reorder Points and Safety Stock Levels: Automate triggers for replenishment. These parameters ensure timely replenishment, protect against unexpected demand spikes, and maintain a stable production rhythm.

Use FIFO or FEFO for Seasonal Goods: This practice prevents material expiration, supports efficient rotation, and reduces waste — especially for color-sensitive fabrics, dyes, or packaging.

Track KPIs: Focus on material turnover rate, carrying cost, and stock accuracy. Tracking these KPIs allows continuous improvement and gives managers visibility into bottlenecks or inefficiencies.

Foster Cross-Functional Communication: Connect procurement, warehouse, and production teams. Integrated communication platforms and shared dashboards eliminate data silos and ensure everyone operates from the same, updated information.

Digitize Material Tracking: Implement ERP/MRP tools to centralize visibility. Digital tracking ensures real-time visibility into stock movement, on-order quantities, and usage trends .

Monitor Inventory Health with Dashboards: Visualize stock risk, reorder alerts, and waste ratios by using cloud-based dashboards. Some systems also provide “inventory health” indicators that help teams prioritize actions, cut waste, and maintain a steady production flow.

>> Explore digital solutions in raw material and inventory management:

Top 10 AI Fashion Inventory Management Software Solutions

Top 7 AI-Powered Demand Forecasting Tools for Fashion

Raw Material Management on the Nūl Platform

At Nūl, raw material management isn’t just a spreadsheet — it’s a real-time intelligence layer for fashion production.

Core Features:

Automated demand forecasting for material needs

Integrated supplier tracking and performance scoring

Inventory health dashboards across locations

Smart reorder alerts and consumption tracking

Metrics Tracked:

Material turnover rate

Stock accuracy (%)

Supplier lead time

Material waste percentage

Reorder and fill rates

Tracking Methods:

API syncs with Shopify, ERP, or production software

AI-driven demand modeling

Real-time PO and stock reconciliation

Value to Users:

Operational efficiency: No more stockouts or over-ordering.

Sustainability: Reduced deadstock and waste.

Visibility: Unified data from procurement to production.

Scalability: Works for small brands or multi-factory enterprises.

>> Explore more raw material management solutions:

Top 8 Best Raw Material Inventory Management Software

Top 7 Best Inventory Management Software with Bill of Materials

Conclusion

Raw material management is more than logistics — it’s the heart of production planning and sustainability. When materials flow smoothly, so does everything else: forecasting, production, and profitability.

By combining accurate forecasting, disciplined procurement, and AI-powered visibility, brands can unlock operational resilience — transforming their supply chains from reactive to predictive.

Article by

Nūl Content Team

An Experienced Research & Knowledge Team

An Experienced Research & Knowledge Team

The Nūl Content Team combines expertise in technology, fashion, and supply chain management to deliver clear, practical insights. Guided by Nūl’s mission to end overproduction, we create content that helps brands forecast demand more accurately, optimize inventory, and build sustainable operations. Every piece we publish is grounded in real-world experience, ensuring it’s both credible and actionable.

LinkedIn Profile