Make to Stock vs Make to Order: Key Differences & What to Choose?

Dec 18, 2025

Make-to-stock (MTS) produces items based on sales forecasts before customers place an order, while make-to-order (MTO) only produces items after an order is placed.

When a fashion brand decides how to build its products, it faces one core choice: Should we build it before the customer buys it, or build it after they order it? Your choice determines how fast you deliver, how much inventory you hold, and how much risk you take on.

Choosing between MTS and MTO, or deciding on a mix of both, is not an easy decision. This blog will explain them both and help you decide which one is best for your brand. Finally, you'll understand when to use MTS and MTO and how a mixed setup can benefit from both.

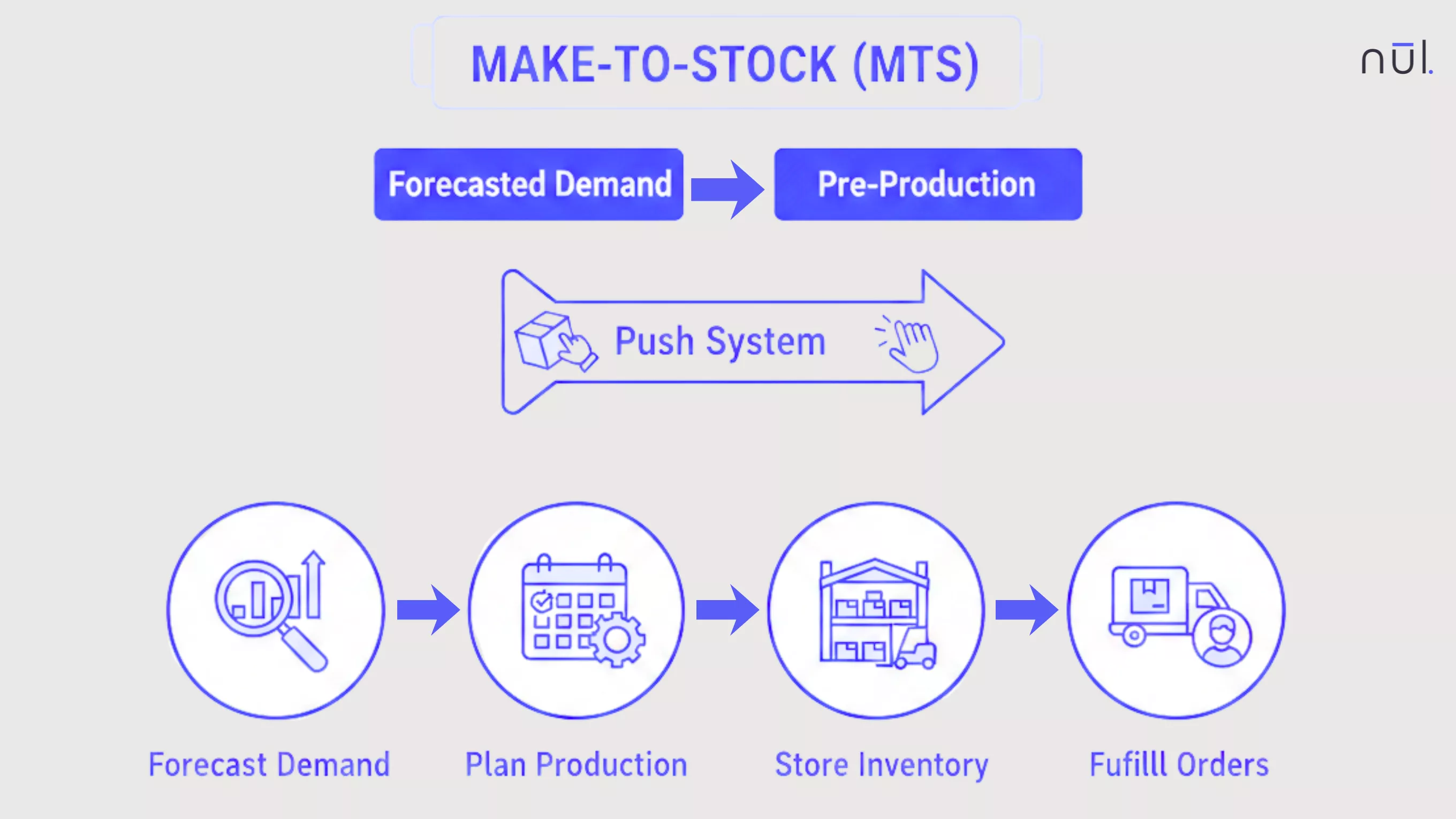

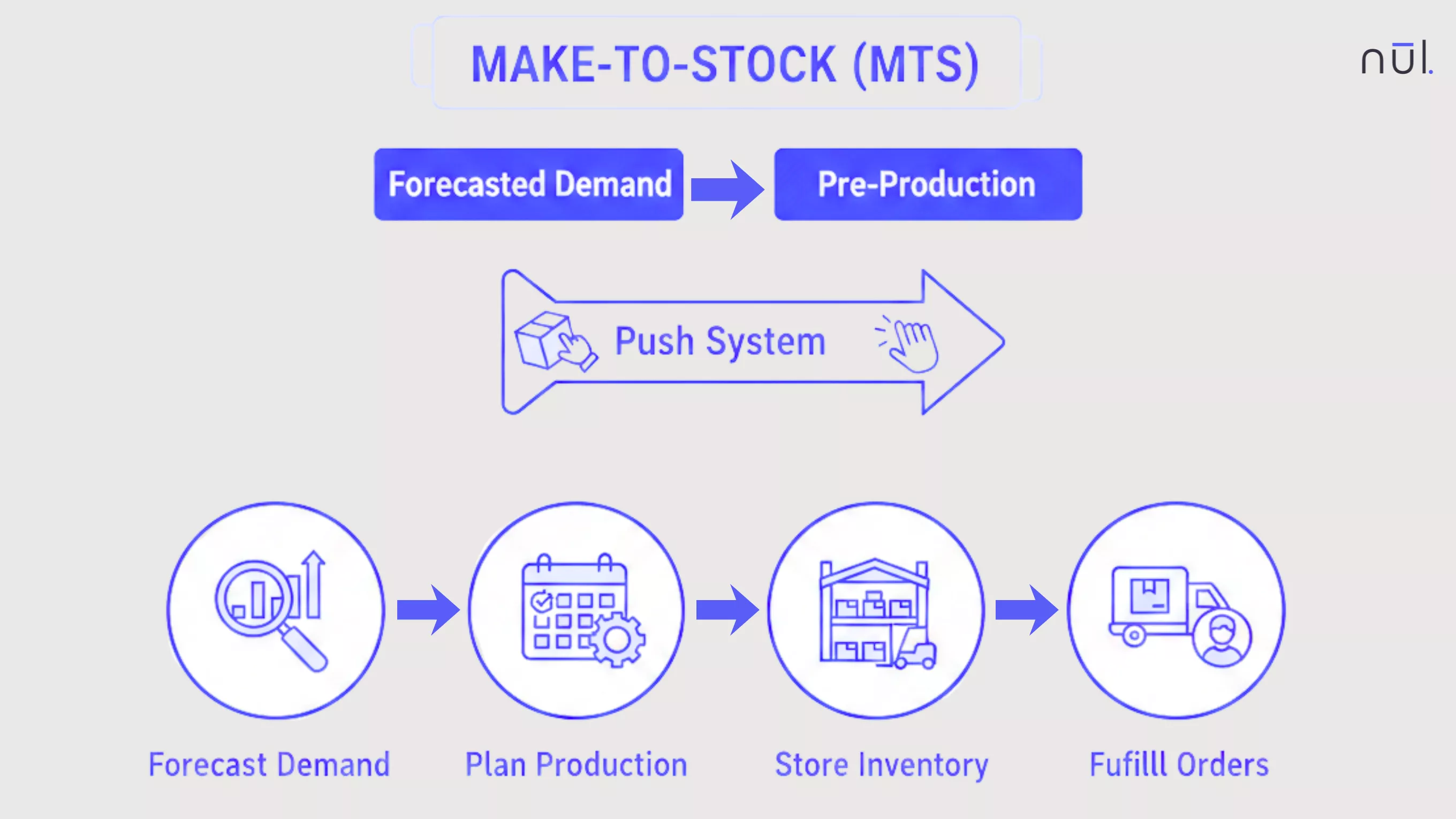

What is Make to Stock (MTS)?

Make-to-Stock (MTS) is a production approach where a business creates products based on forecasted customer demand before a specific order.

Make-to-Stock = Push System: Products are pushed to production from sales forecasts.

Here is a basic process of Make to Stock:

Forecast Demand: Brands use past sales data, trends, and forecasts to predict the number of products customers will buy in a certain period.

Plan Production: The production schedule and quantity are set well in advance based on the forecast.

Store Inventory: Once a product is finished, it is kept in warehouses or distribution centers until a customer places an order.

Fulfill Orders: When an order is received, the product is immediately shipped without waiting for manufacturing.

Make-to-Stock (MTS) creates products based on forecasted customer demand before a specific order.

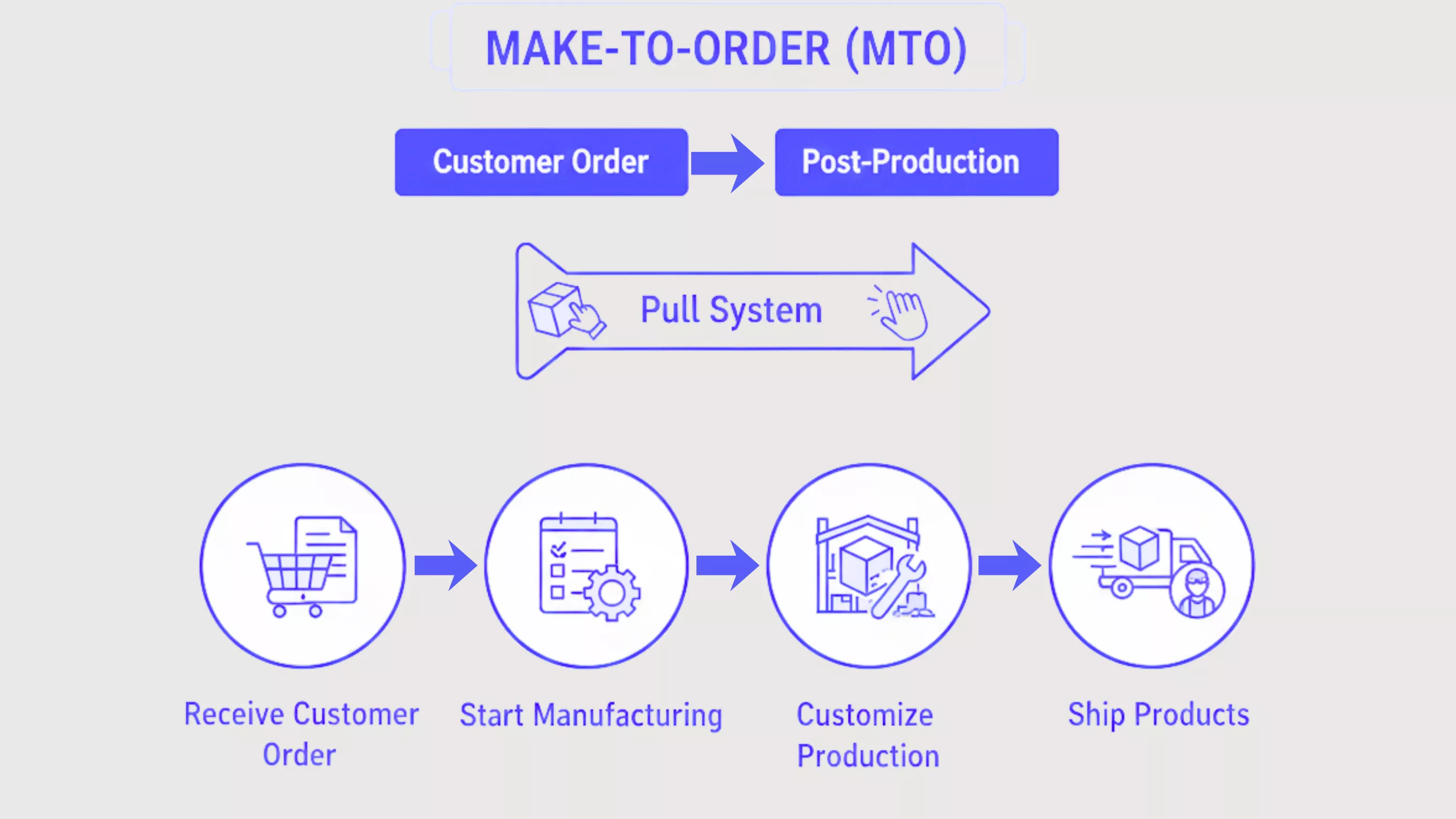

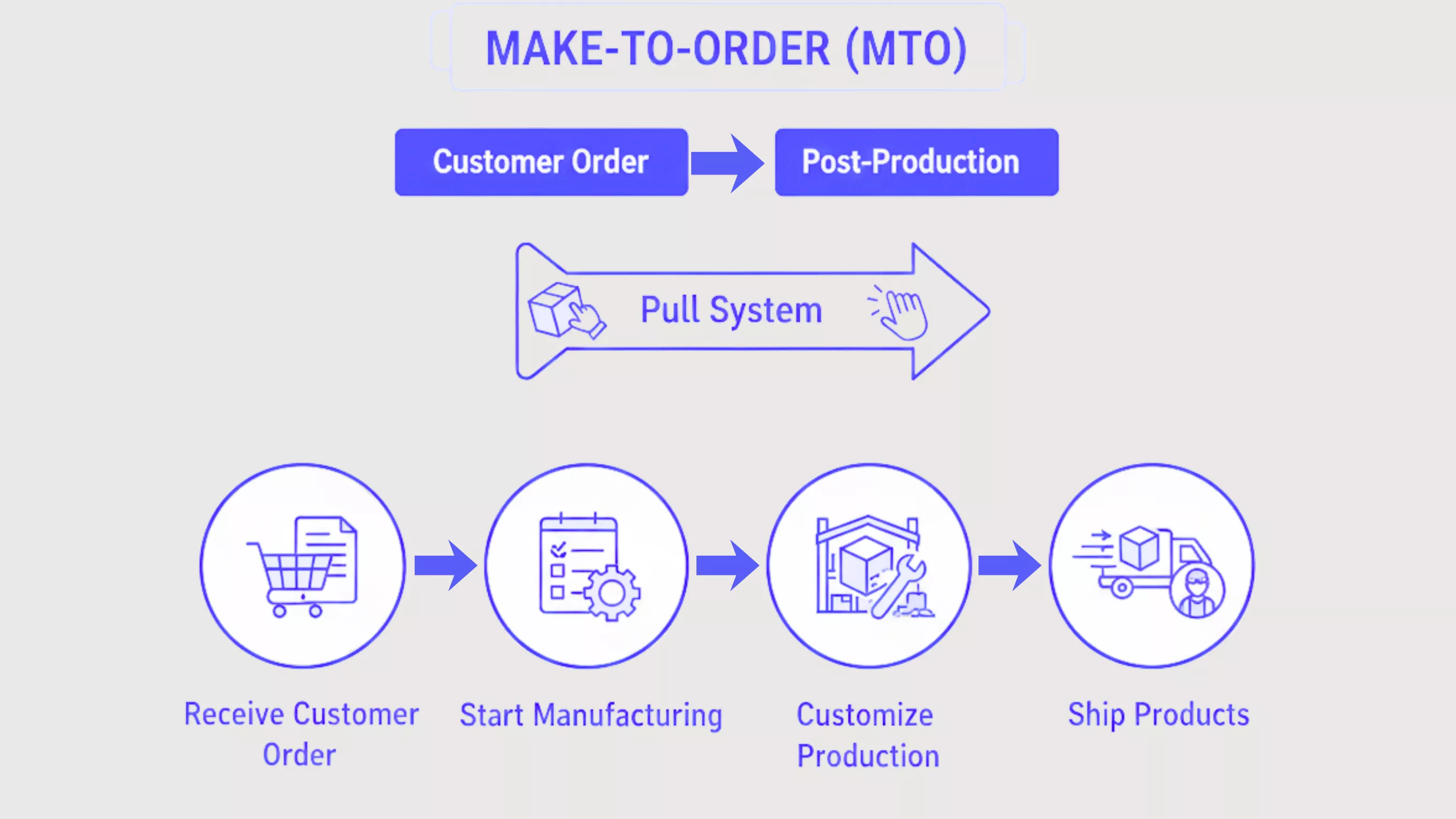

What is Make to Order (MTO)?

Make-to-Order (MTS) is a production approach where a business only creates products after a customer places an order.

Make-to-Order = Pull System: Products are pulled to production from a customer’s purchase.

Here is a basic process of Make to Order:

Receive Customer Order: The sales order is processed and confirmed.

Start Manufacturing: A work order is created for planning, raw material sourcing, and all steps follow the customer’s exact needs (bill of materials and process).

Customize Production: The product is built or adjusted to match the customer’s specifications, giving a high level of personalization.

Ship Products: Once the item is completed and checked, it is shipped straight to the customer, with no need to store it as finished inventory.

Make-to-Order (MTS) only creates products after a customer places an order.

What are Advantages and Disadvantages of MTS vs MTO?

Make-to-Stock (MTS)

MTS is the traditional standard for most retail and fast fashion brands.

Advantages:

Fast Fulfillment: Since items are pre-made and always ready, shipping happens immediately.

Economies of Scale: Producing thousands of identical shirts at once lowers the cost per garment. You can also negotiate better bulk prices with fabric suppliers.

Predictable Workflows: Factory schedules are set months in advance, allowing for smoother labor management and machine utilization.

Disadvantages:

Waste: Overproduction is one of the fashion industry’s biggest environmental issues. Unsold clothes often end up in landfills.

High Overhead: You must pay for large warehouse spaces and insurance to protect your finished garments.

Tied-up Capital: Your cash is stuck in the form of clothes sitting on a shelf, meaning you have less money available for marketing or new designs.

Make-to-Order (MTO)

MTO is a slow fashion approach preferred by luxury brands who follow sustainable fashion trends.

Advantages:

Zero Inventory Waste: You only use the fabric and labor required for a sold item.

Better Cash Flow: Since customers usually pay when they place an order, the company gets paid in cash before the costs of production are even spent.

High Customer Satisfaction: Buyers value the made just for me experience with less the likelihood of returns due to poor fit.

Disadvantages:

Higher Unit Costs: Without mass production, your cost for labor and individual shipping is much higher. This often requires a higher retail price point.

Loss of Scale: You pay more for every yard of fabric and every hour of labor because you aren't producing in bulk.

Operational Stress: Your team must be ready to work at 100% capacity the moment a viral trend hits, which is exhausting and difficult to manage.

Make to Stock vs Make to Order: Key Differences in Details

Here is a quick comparison before diving into details:

Feature | Make to Stock (MTS) | Make to Order (MTO) |

|---|---|---|

Production Trigger | Predicted demand (push system). | Customer order (pull system). |

Production Timing | Before a customer places an order. | After a customer places an order. |

Lead Time | Shorter, as items are ready for fast delivery. | Longer, as there are no available items for shipment before the order is placed. |

Inventory | Higher inventory holding costs as finished goods are stored in stock. | Lower inventory costs, as finished goods are shipped straight to customers instead of being kept in stock. |

Customization | Limited; products are standardized. | High; products can be customized to specific customer needs. |

Demand Pattern | Stable, predictable, and high-volume demand. | Fluctuating, unpredictable, and low-volume demand. |

Risk | Overproduction, excess inventory, and obsolescence if demand forecasts are inaccurate. | Not being able to meet demand quickly enough, longer wait times for customers. |

Pros |

|

|

Examples |

|

|

Production Timing

Make to Stock (MTS): Production happens before any customer places an order. The brand looks at past sales, current trends, and forecast models, then decides how many units to produce for the upcoming season. This is a proactive approach where products are already finished and sitting in the warehouse to wait for shipping.

Make to Order (MTO): Production begins only after a confirmed order. This is a reactive approach where brands wait to know actual demand instead of predictions. Once the order arrives, the team starts planning, cutting, sewing, finishing, and getting the item ready to ship straight to buyers.

Lead Time

Make to Stock (MTS): Needs shorter lead time and has faster delivery because the lead time for the customer is just the time for picking, packing, and shipping. Since the garments are already finished and sitting in the warehouse, brands can offer immediate or "next-day" delivery options.

Make to Order (MTO): Requires a much longer lead time because the customer must wait for the entire production cycle to finish. The total wait time includes sourcing materials, garment production, and final delivery.

Inventory Costs

Make to Stock (MTS): The stock storage and insurance costs because brands hold a high volume of finished goods inventory. There is a financial risk that if the stock doesn't sell as expected, the brand is left with expensive, aging inventory that must be discounted.

Make to Order (MTO): The holding costs are much lower because there aren't many finished products in stock. Everything is sent out as soon as it's done with MTO. However, brands still need to manage an exact inventory of raw materials to ensure they can start production when an order arrives.

Customization

Make to Stock (MTS): Customization is extremely limited because garments are mass-produced in standardized sizes, colors, and styles. The brand decides the final design months in advance, and the consumer chooses from the pre-made options available in the warehouse.

Make to Order (MTO): This model has a high degree of customization, as the garment is built to meet the specific needs of an individual buyer. Customers can select specific fabrics, request custom measurements, or choose unique finishing details that make the item unique.

Demand Pattern

Make to Stock (MTS): This strategy is best suited for stable, predictable, and high-volume demand. In fashion, for example, basic or essential items like plain white t-shirts or standard black leggings have consistent sales numbers year-round and are easy to forecast.

Make to Order (MTO): This method is ideal for highly fluctuating, unpredictable, low-volume demand. Brands with luxury fashion, couture, or niche seasonal trends prefer this method as they cannot be certain about how many people will want a specific high-end design.

Risk

Make to Stock (MTS): The biggest threat is the risk of overproduction and obsolescence. If a trend fades or a forecast is wrong, the brand is stuck with a warehouse full of unsold clothes. These inventory lose value every day, then finally leading to deep discounts or dead stock.

Make to Order (MTO): The primary risk is a loss of sales because of long wait times. As production is reactive, what happens if a sudden spike in popularity? The brand cannot produce quickly and in time, and frustrated customers won’t want to wait weeks for a garment to be sewn and shipped.

How to Choose the Right Strategy for Your Fashion Brand?

Make-to-Stock or Make-to-Order? It depends on the price point, market position, and type of products your brand sells.

Choose Make-to-Stock (MTS) if:

You sell basics: Your collection includes high-volume essentials like T-shirts or socks with steady demand.

Speed is your priority: Your customers expect immediate shipping and are not looking for customization.

You have reliable data: You have years of sales history that allow you to create accurate demand forecasts.

Cost-efficiency is key: You need the low per-unit costs that come with mass production and economies of scale.

Choose Make-to-Order (MTO) if:

You are a luxury or custom brand: Your products are high-value, and your customers value uniqueness and a perfect fit.

You want to be sustainable: You want to follow lean manufacturing principles by eliminating overproduction and textile waste.

You have low storage space: You want to avoid the high overhead costs and risks of holding large amounts of finished inventory.

You want to try new styles: You have unique and new fashion ideas, and you want to know how customers will react to your designs, in a negative or positive way.

FAQs

1. Can we combine MTS and MTO?

Yes, many fashion brands use a hybrid approach to balance risk and efficiency. In this model, a brand uses Make-to-Stock (MTS) for basic items with steady, predictable demand like plain t-shirts. Otherwise, they use Make-to-Order (MTO) for seasonal, high-fashion, or experimental pieces. This is suitable for brands with wide range of product types.

2. What is Assemble-to-Order (ATO)?

Assemble-to-Order is a middle-ground strategy where a brand keeps common parts or semi-finished pieces ready in stock (like MTS), but completes the final assembly or customization only after a customer order arrives (like MTO).

For example: Keeping a stock of plain white t-shirts ready and only printing a specific graphic on them once a buyer makes a purchase.

ATO offers much faster delivery times than pure MTO while still reducing the amount of finished goods inventory a brand needs to store.

Key Takeaways

Make to Stock and Make to Order are not just technical terms and they shape how your whole business runs. MTS gives speed and smooth operations, but needs solid forecasts and accepts inventory risk. MTO gives flexibility and reduces unsold stock, but demands longer lead times and stronger planning. In reality, most brands, especially in fashion, need a mix of both.

The right answer is rarely “all MTS” or “all MTO”. It’s about matching each product, channel, and customer promise to the model that fits best. Then, you need to back that choice with data, clear processes, and the right systems.

Hope this blog will help you have a suitable choice for your brand.

Article by

Nūl Content Team

An Experienced Research & Knowledge Team

The Nūl Content Team combines expertise in technology, fashion, and supply chain management to deliver clear, practical insights. Guided by Nūl’s mission to end overproduction, we create content that helps brands forecast demand more accurately, optimize inventory, and build sustainable operations. Every piece we publish is grounded in real-world experience, ensuring it’s both credible and actionable.

LinkedIn Profile

More From Blog

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

More From Blog

Make to Stock vs Make to Order: Key Differences & What to Choose?

Dec 18, 2025

Make-to-stock (MTS) produces items based on sales forecasts before customers place an order, while make-to-order (MTO) only produces items after an order is placed.

When a fashion brand decides how to build its products, it faces one core choice: Should we build it before the customer buys it, or build it after they order it? Your choice determines how fast you deliver, how much inventory you hold, and how much risk you take on.

Choosing between MTS and MTO, or deciding on a mix of both, is not an easy decision. This blog will explain them both and help you decide which one is best for your brand. Finally, you'll understand when to use MTS and MTO and how a mixed setup can benefit from both.

What is Make to Stock (MTS)?

Make-to-Stock (MTS) is a production approach where a business creates products based on forecasted customer demand before a specific order.

Make-to-Stock = Push System: Products are pushed to production from sales forecasts.

Here is a basic process of Make to Stock:

Forecast Demand: Brands use past sales data, trends, and forecasts to predict the number of products customers will buy in a certain period.

Plan Production: The production schedule and quantity are set well in advance based on the forecast.

Store Inventory: Once a product is finished, it is kept in warehouses or distribution centers until a customer places an order.

Fulfill Orders: When an order is received, the product is immediately shipped without waiting for manufacturing.

Make-to-Stock (MTS) creates products based on forecasted customer demand before a specific order.

What is Make to Order (MTO)?

Make-to-Order (MTS) is a production approach where a business only creates products after a customer places an order.

Make-to-Order = Pull System: Products are pulled to production from a customer’s purchase.

Here is a basic process of Make to Order:

Receive Customer Order: The sales order is processed and confirmed.

Start Manufacturing: A work order is created for planning, raw material sourcing, and all steps follow the customer’s exact needs (bill of materials and process).

Customize Production: The product is built or adjusted to match the customer’s specifications, giving a high level of personalization.

Ship Products: Once the item is completed and checked, it is shipped straight to the customer, with no need to store it as finished inventory.

Make-to-Order (MTS) only creates products after a customer places an order.

What are Advantages and Disadvantages of MTS vs MTO?

Make-to-Stock (MTS)

MTS is the traditional standard for most retail and fast fashion brands.

Advantages:

Fast Fulfillment: Since items are pre-made and always ready, shipping happens immediately.

Economies of Scale: Producing thousands of identical shirts at once lowers the cost per garment. You can also negotiate better bulk prices with fabric suppliers.

Predictable Workflows: Factory schedules are set months in advance, allowing for smoother labor management and machine utilization.

Disadvantages:

Waste: Overproduction is one of the fashion industry’s biggest environmental issues. Unsold clothes often end up in landfills.

High Overhead: You must pay for large warehouse spaces and insurance to protect your finished garments.

Tied-up Capital: Your cash is stuck in the form of clothes sitting on a shelf, meaning you have less money available for marketing or new designs.

Make-to-Order (MTO)

MTO is a slow fashion approach preferred by luxury brands who follow sustainable fashion trends.

Advantages:

Zero Inventory Waste: You only use the fabric and labor required for a sold item.

Better Cash Flow: Since customers usually pay when they place an order, the company gets paid in cash before the costs of production are even spent.

High Customer Satisfaction: Buyers value the made just for me experience with less the likelihood of returns due to poor fit.

Disadvantages:

Higher Unit Costs: Without mass production, your cost for labor and individual shipping is much higher. This often requires a higher retail price point.

Loss of Scale: You pay more for every yard of fabric and every hour of labor because you aren't producing in bulk.

Operational Stress: Your team must be ready to work at 100% capacity the moment a viral trend hits, which is exhausting and difficult to manage.

Make to Stock vs Make to Order: Key Differences in Details

Here is a quick comparison before diving into details:

Feature | Make to Stock (MTS) | Make to Order (MTO) |

|---|---|---|

Production Trigger | Predicted demand (push system). | Customer order (pull system). |

Production Timing | Before a customer places an order. | After a customer places an order. |

Lead Time | Shorter, as items are ready for fast delivery. | Longer, as there are no available items for shipment before the order is placed. |

Inventory | Higher inventory holding costs as finished goods are stored in stock. | Lower inventory costs, as finished goods are shipped straight to customers instead of being kept in stock. |

Customization | Limited; products are standardized. | High; products can be customized to specific customer needs. |

Demand Pattern | Stable, predictable, and high-volume demand. | Fluctuating, unpredictable, and low-volume demand. |

Risk | Overproduction, excess inventory, and obsolescence if demand forecasts are inaccurate. | Not being able to meet demand quickly enough, longer wait times for customers. |

Pros |

|

|

Examples |

|

|

Production Timing

Make to Stock (MTS): Production happens before any customer places an order. The brand looks at past sales, current trends, and forecast models, then decides how many units to produce for the upcoming season. This is a proactive approach where products are already finished and sitting in the warehouse to wait for shipping.

Make to Order (MTO): Production begins only after a confirmed order. This is a reactive approach where brands wait to know actual demand instead of predictions. Once the order arrives, the team starts planning, cutting, sewing, finishing, and getting the item ready to ship straight to buyers.

Lead Time

Make to Stock (MTS): Needs shorter lead time and has faster delivery because the lead time for the customer is just the time for picking, packing, and shipping. Since the garments are already finished and sitting in the warehouse, brands can offer immediate or "next-day" delivery options.

Make to Order (MTO): Requires a much longer lead time because the customer must wait for the entire production cycle to finish. The total wait time includes sourcing materials, garment production, and final delivery.

Inventory Costs

Make to Stock (MTS): The stock storage and insurance costs because brands hold a high volume of finished goods inventory. There is a financial risk that if the stock doesn't sell as expected, the brand is left with expensive, aging inventory that must be discounted.

Make to Order (MTO): The holding costs are much lower because there aren't many finished products in stock. Everything is sent out as soon as it's done with MTO. However, brands still need to manage an exact inventory of raw materials to ensure they can start production when an order arrives.

Customization

Make to Stock (MTS): Customization is extremely limited because garments are mass-produced in standardized sizes, colors, and styles. The brand decides the final design months in advance, and the consumer chooses from the pre-made options available in the warehouse.

Make to Order (MTO): This model has a high degree of customization, as the garment is built to meet the specific needs of an individual buyer. Customers can select specific fabrics, request custom measurements, or choose unique finishing details that make the item unique.

Demand Pattern

Make to Stock (MTS): This strategy is best suited for stable, predictable, and high-volume demand. In fashion, for example, basic or essential items like plain white t-shirts or standard black leggings have consistent sales numbers year-round and are easy to forecast.

Make to Order (MTO): This method is ideal for highly fluctuating, unpredictable, low-volume demand. Brands with luxury fashion, couture, or niche seasonal trends prefer this method as they cannot be certain about how many people will want a specific high-end design.

Risk

Make to Stock (MTS): The biggest threat is the risk of overproduction and obsolescence. If a trend fades or a forecast is wrong, the brand is stuck with a warehouse full of unsold clothes. These inventory lose value every day, then finally leading to deep discounts or dead stock.

Make to Order (MTO): The primary risk is a loss of sales because of long wait times. As production is reactive, what happens if a sudden spike in popularity? The brand cannot produce quickly and in time, and frustrated customers won’t want to wait weeks for a garment to be sewn and shipped.

How to Choose the Right Strategy for Your Fashion Brand?

Make-to-Stock or Make-to-Order? It depends on the price point, market position, and type of products your brand sells.

Choose Make-to-Stock (MTS) if:

You sell basics: Your collection includes high-volume essentials like T-shirts or socks with steady demand.

Speed is your priority: Your customers expect immediate shipping and are not looking for customization.

You have reliable data: You have years of sales history that allow you to create accurate demand forecasts.

Cost-efficiency is key: You need the low per-unit costs that come with mass production and economies of scale.

Choose Make-to-Order (MTO) if:

You are a luxury or custom brand: Your products are high-value, and your customers value uniqueness and a perfect fit.

You want to be sustainable: You want to follow lean manufacturing principles by eliminating overproduction and textile waste.

You have low storage space: You want to avoid the high overhead costs and risks of holding large amounts of finished inventory.

You want to try new styles: You have unique and new fashion ideas, and you want to know how customers will react to your designs, in a negative or positive way.

FAQs

1. Can we combine MTS and MTO?

Yes, many fashion brands use a hybrid approach to balance risk and efficiency. In this model, a brand uses Make-to-Stock (MTS) for basic items with steady, predictable demand like plain t-shirts. Otherwise, they use Make-to-Order (MTO) for seasonal, high-fashion, or experimental pieces. This is suitable for brands with wide range of product types.

2. What is Assemble-to-Order (ATO)?

Assemble-to-Order is a middle-ground strategy where a brand keeps common parts or semi-finished pieces ready in stock (like MTS), but completes the final assembly or customization only after a customer order arrives (like MTO).

For example: Keeping a stock of plain white t-shirts ready and only printing a specific graphic on them once a buyer makes a purchase.

ATO offers much faster delivery times than pure MTO while still reducing the amount of finished goods inventory a brand needs to store.

Key Takeaways

Make to Stock and Make to Order are not just technical terms and they shape how your whole business runs. MTS gives speed and smooth operations, but needs solid forecasts and accepts inventory risk. MTO gives flexibility and reduces unsold stock, but demands longer lead times and stronger planning. In reality, most brands, especially in fashion, need a mix of both.

The right answer is rarely “all MTS” or “all MTO”. It’s about matching each product, channel, and customer promise to the model that fits best. Then, you need to back that choice with data, clear processes, and the right systems.

Hope this blog will help you have a suitable choice for your brand.

Article by

Nūl Content Team

An Experienced Research & Knowledge Team

An Experienced Research & Knowledge Team

The Nūl Content Team combines expertise in technology, fashion, and supply chain management to deliver clear, practical insights. Guided by Nūl’s mission to end overproduction, we create content that helps brands forecast demand more accurately, optimize inventory, and build sustainable operations. Every piece we publish is grounded in real-world experience, ensuring it’s both credible and actionable.

LinkedIn Profile