A Practical Guide to Manage Inventory for Seasonal Products

Dec 25, 2025

Seasonal inventory management is the strategic process of forecasting, planning, buying, allocating, and managing stock to match predictable demand spikes.

Seasonality has always shaped the fashion industry, but in 2026, it matters more than ever. Weather volatility, shorter trend cycles, influencer-driven demand spikes, and tighter cash flow conditions mean that getting seasonal inventory wrong is more expensive than ever. A single forecasting mistake can lead to excess stock, heavy markdowns, or missed sales during peak demand.

Fashion brands frequently experience:

Overstocked end-of-season inventory that ties up cash;

Stockouts during peak weeks;

Poor sell-through due to mistimed buying;

Margin erosion from reactive discounting.

But, there are still brands that manage seasonal inventory well and outperform peers with higher sell-through, healthier cash flow, and more predictable operations. What are the tips? In this blog, we guide you through seasonal inventory management, how to manage them, and best strategies for your future success.

What Is Seasonal Inventory Management?

Seasonal inventory management is the strategic process of forecasting, planning, buying, allocating, and managing stock to match predictable demand spikes due to weather, holidays, or events.

In fashion, this includes products that:

Peak for a limited window;

Decline rapidly after the season ends;

Lose value quickly if demand timing is missed.

It focuses on having enough inventory to meet peak-season demand without overstocking, using data, AI/analytics, and flexible supply chains to track real-time changes, adjust procurement, and plan efficient clearance after the season.

The goal is to maximize profit during high-demand periods, prevent stockouts, and minimize losses from excess inventory once demand falls.

Some seasonal inventory examples in fashion:

Swimwear & resortwear → Spring / Summer, closely tied to weather and travel seasons.

Coats, knitwear, thermals → Fall / Winter, with short selling windows in colder regions.

Festive & holiday dresses → October–December, driven by year-end events and celebrations.

Occasionwear → Wedding seasons, festive calendars, which vary by region and culture.

Back-to-school apparel → Regional academic cycles, often with sharp demand spikes before term starts.

Unlike evergreen basics, seasonal inventory has high timing sensitivity, selling late often means selling at a loss.

4 Common Types of Seasonal Demand in Fashion

Event / Holiday Demand

This type of demand is the most predictable because the calendar provides clear signals. Specific occasions such as weddings, festivals, or year-end celebrations usually happen at the same time each year. In this demand type, sales rise sharply within a short window and fall quickly once the event ends. You need to make timing and stock depth exact.

Examples: Lunar New Year, Black Friday /Cyber Monday, wedding seasons, graduation periods.

Strategy: This demand requires backward scheduling. This means working back from the event date to calculate when inventory must arrive in stores. In most cases, stock needs to be available 4–6 weeks before the event to capture early demand and avoid last-minute shortages.

Weather-Driven Demand

Unlike holidays, weather demand is more volatile. It rises or falls based on temperature and climate conditions. Because weather patterns shift each year due to global climate changes, this demand is increasingly harder to predict and need adjustments in season.

Examples: A warm winter leads to an overstock of heavy parkas, unseasonable heatwaves in Spring drives early sandal sales.

Strategy: Implement demand sensing technology to adjust replenishment based on short-term weather forecasts rather than just historical averages.

Cultural / Geographic Demand

Seasonality varies by region and culture, so using a single global calendar cannot meet demand in every market. For example, winter in Australia happens at a different time than in Europe or North America, so how can you sell the same seasonal products across those regions? Thus, brands selling globally must plan inventory by market, not by a single global season.

Examples: Winter in the Northern Hemisphere is Summer in the Southern, Linen shirts can be wore everyday in hot climates, but are only popular during summer holidays in colder regions.

Strategy: Apply localized assortment planning. Avoid "pushed" inventory from headquarters, instead, "pull" inventory based on regional climate and cultural relevance (e.g., specific colors for regional festivals).

>> You can consider: 10 Best Assortment Planning Software for Fashion Brands

Promotional Demand

This demand is intentionally created by the marketing department, not by the external environment. Through planned sales, product launches, or influencer drops, brands can create short-term demand spikes. Although this demand type is predictable on the calendar, it still carry risk if marketing response is weaker or stronger than expected.

Examples: Limited-edition drops, influencer collaborations, or mid-season flash sales.

Strategy: Close synchronization between Marketing and Supply Chain. The "Bullwhip Effect" is most dangerous here, where a small spike in promotional demand leads to massive over-ordering if not communicated clearly.

Common Types of Seasonal Demand in Fashion

Benefits of Effective Seasonal Inventory Management

Maximizes Revenue: Having the right products in the right place at the right time means brands can capture the highest possible volume of transactions during the narrow window of consumer intent.

Improves Profitability: Better planning leads to higher full-price sell-through and fewer last-minute markdowns. Every item sold at the start of the season at MSRP is worth significantly more than two items sold at a 50% discount during clearance.

Enhances Customer Satisfaction: Nothing damages customer retention like stockout during a peak shopping moment (e.g., no winter coats in stock during a December cold snap). Besides increased brand loyalty, there are no backorders and lost sales during peak periods as well.

Optimizes Working Capital: Reducing Days Sales of Inventory (DSI) means working capital isn't tied up in unsold end-of-season stock. This liquidity allows the business to reinvest in new collections or core product for the next season.

Reduces Losses: Optimized stock levels reduce holding costs including warehouse labor, insurance, and the physical space required for aged inventory. Also, there are fewer forced liquidation decisions at the end of the season.

>> Explore further tips: 16 Best Cost Reduction Strategies in Inventory Management

Practical Guide: How to Manage Inventory for Seasonal Products?

1. Identify Seasonal Products

Clearly separate your evergreen basics (sold year-round) from your seasonal items. Also, there are different types in seasonal products like:

Pure Seasonal: Items with zero demand outside the window (e.g., Christmas ornaments).

Seasonal Peak: Evergreen items that see a 5x-10x spike (e.g., white t-shirts during Back-to-School).

Trend Seasonal: Fashion items that are both seasonal and high-risk due to short-lived styles or trends that may not repeat next year.

Tip: Tag seasonal items in your ERP/IMS with specific "Season Tags" to prevent automated replenishment systems from ordering them during the off-season.

2. Analyze Past Seasonal Performance

Start by reviewing last season’s results to understand where money was lost, not just what sold. Then, you can adjust next season’s buys, timing, and pricing strategy based on what actually happened.

Stockout Analysis: Identify products that sold out too early. For example, If you sold out of a parka in November, how much revenue did you leave on the table in December?

Markdown Depth: Review how much discounting was needed to clear inventory. Did you achieve a 70% sell-through at full price, or was your profit eaten by forced 50% discounts?

Key KPIs to measure seasonal inventory performance:

Sell-through rate (%);

Markdown depth (how much did you have to discount to move it?);

Stockout timing (did you run out before the peak?);

Inventory Turnover;

Days to Sell Inventory (DSI);

Average Inventory Levels;

Stockout Rate;

Rate of Return;

Backorder Rate.

3. Build a Seasonal Demand Forecast

Forecast demand by:

Season phase (early, peak, late)

Channel (online, retail, wholesale): E-commerce usually peaks earlier (shipping lead times) than physical retail (last-minute shoppers).

Location or region: Winter demand for boots hits Minneapolis three weeks before it hits Seattle.

This gives you a more realistic view than using one total forecast.

4. Align Forecast With Supplier Lead Times

Negotiate fabric or raw component holding with your suppliers. Instead of finishing the full product upfront, have suppliers hold base materials and delay final production until demand becomes clearer.

You know, long supplier lead times increase risk in seasonal inventory. When production takes too long, decisions must be made before real demand is visible, leaving little room to adjust.

If this is agreed, you can:

Commit early to raw materials;

Delay style, color, or size decisions;

Shorten final production and shipping.

5. Plan Inventory Levels by Season Phases

Avoid front-loading that ships 100% of your stock to stores on Day 1. Instead, deploy 40-50% of your inventory for launch to fill the floor/site. Hold the remaining 50% at a central Distribution Center (DC) to replenish the specific locations or sizes that are selling fastest.

6. Allocate Inventory Across Channels and Locations

Use a centralized push-pull system to allocate stock to high-velocity locations while holding back a safety pool in a central warehouse. Allocation can be based on store grading:

Tier 1 Stores: Receive the full depth and breadth of the collection.

Tier 3 Stores: Receive only best-seller items to minimize the risk of fragmented, unsold stock.

>> Read more: What is Inventory Velocity? Formula, Example, & Best Practices

7. Monitor In-Season Performance

During the peak, track Sales Velocity and Weeks of Cover (WOC) weekly. Monthly reports are useless at this time. Some metrics you have to follow:

Sell-Through Rate (STR): (Units Sold / Units Received) × 100.

Weeks of Cover (WOC): Current On-Hand Stock ÷ Average Weekly Sales. If your WOC is higher than the remaining weeks in the season, you have an overstock problem.

Example: If you have 500 units and sell 100/week, you have 5 WOC. If the season ends in 3 weeks, you are overstocked.

8. Adjust Prices and Promotions

Use promotions or markdown strategies to reshape demand, not just react to failure. You can use short-term 10-15% discounts on slow-moving colors or sizes early in the season to re-balance the stock before it becomes dead stock.

Don’t hesitate too long out of fear of hurting your brand or margin. If sales velocity is already slow in week three, a small, controlled 10% flash sale can prevent a 50% clearance sale in week eight.

9. Manage Returns and Reverse Logistics

Prioritize the put-away of seasonal returns over evergreen items. In fact, seasonal products often see higher return rates because they are bought earlier than they are actually used and are tied to short selling windows. As a result, post-season and post-holiday returns can account for 15–30% of seasonal volume. The real risk is time.

Thus, try to inspect fastly and re-enter these products to inventory while demand still exists. As a result, you can maximize full-price recovery and reduce forced markdowns.

10. Execute Rapid Liquidation

Move unsold stock to outlet channels, end-of-season bundles, or third-party liquidators immediately to free up cash for the next season.

You know, once the season is over, the item is no longer an asset, it is a liability taking up space. Every day an item sits on the shelf, it costs you money in opportunity cost.

11. Run a Post-Season Review

Document what worked, what didn’t, and why, like:

What were the "Hero" products?

Where did the forecast fail?

Which suppliers met their lead time?

This is the most skipped step, yet it delivers the highest long-term value. Without a structured post-season review, the same forecasting errors, supplier issues, and allocation mistakes are repeated year after year.

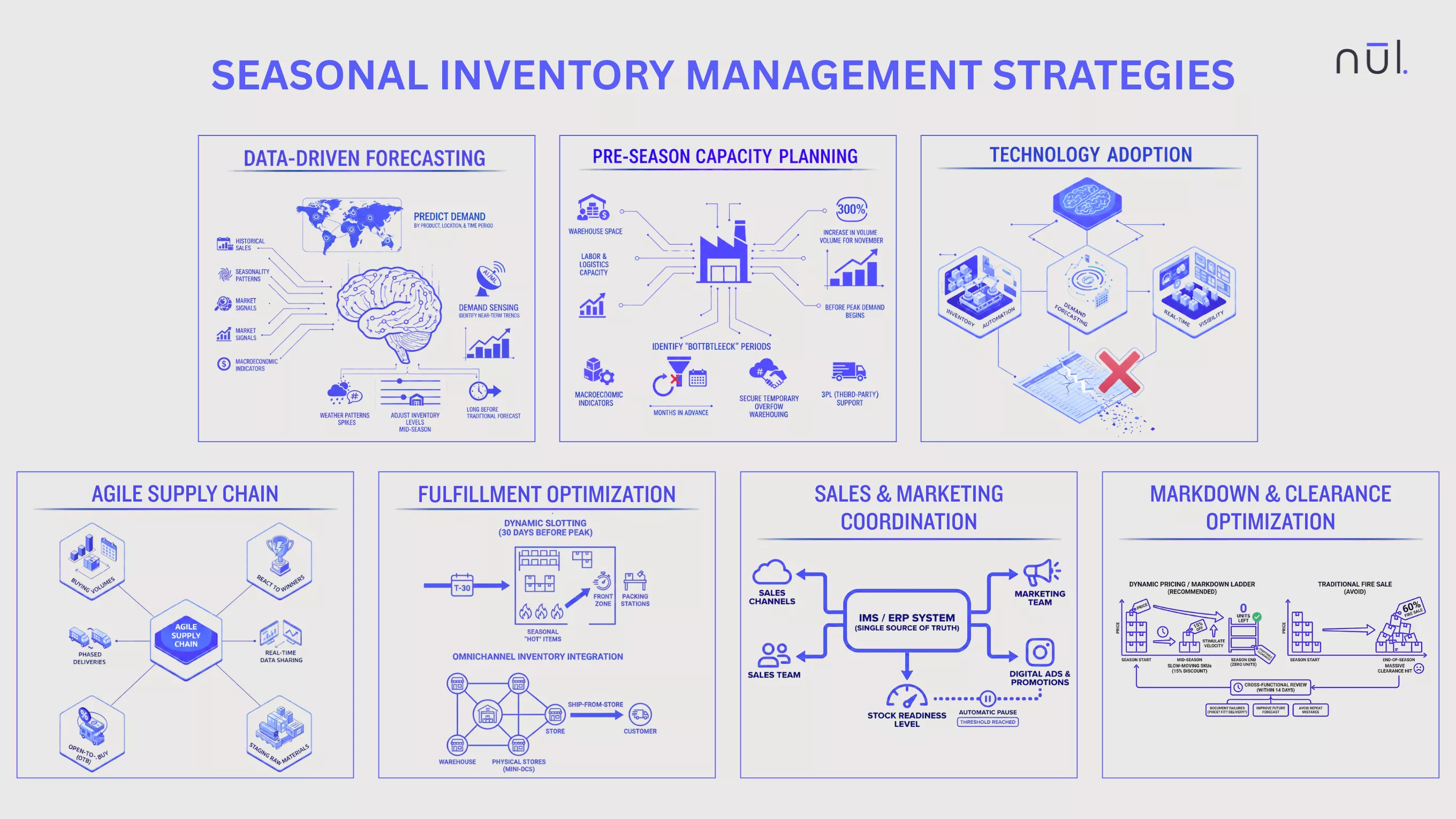

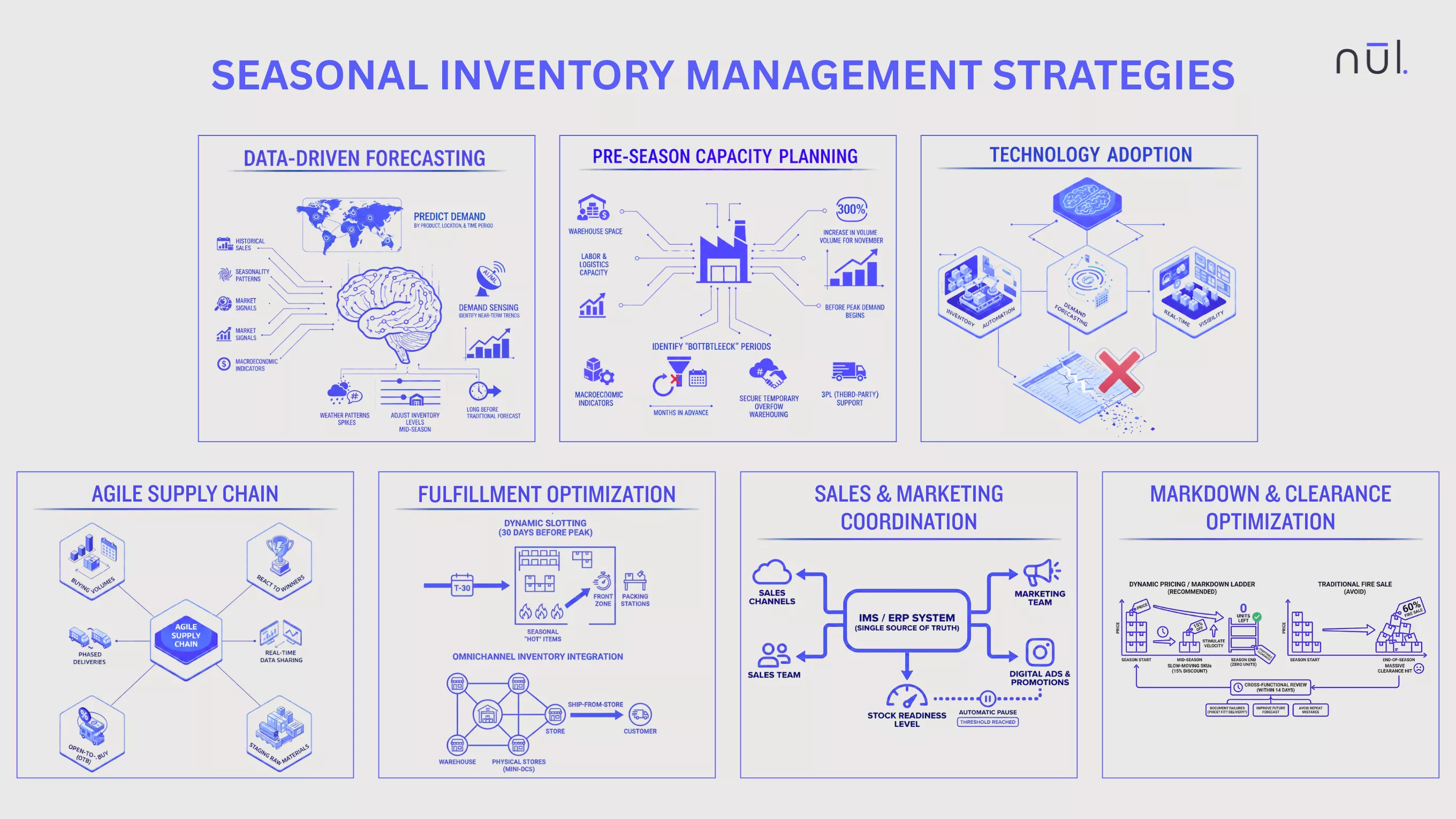

Seasonal Inventory Management Strategies for Fashion Brands

Data-Driven Forecasting

Use historical sales, seasonality patterns, market signals, and even macroeconomic indicators to predict demand by product, location, and time period. Also, use demand sensing backed by AI/ML technology to identify near-term trends. With real-time data like weather patterns or social media spikes, you can adjust inventory levels mid-season, long before a traditional forecast would react.

>> Read more:

14 Best Demand Forecasting Methods in Fashion Supply Chain

Pre-Season Capacity Planning

Prepare warehouse space, labor, and logistics capacity before peak demand begins. Let's identify "bottleneck" periods. If your forecast shows a 300% increase in volume for November, you may need to secure temporary overflow warehousing or 3PL (Third-Party Logistics) support months in advance.

Technology Adoption

Use inventory automation systems, demand forecasting tools, and real-time inventory visibility across all channels. You know, manual spreadsheets are the primary cause of seasonal overstock. Let's use modern systems driven by AI to suggest reorder points based on velocity and automate other tasks.

Agile Supply Chain

Always align your buying volumes with your forecast confidence and manufacturer lead times. Instead of one massive, high-risk pre-season order, negotiate phased deliveries. Commit to a base volume but keep a percentage of your budget "Open-to-Buy" (OTB) to react to winners.

You can also share your real-time sell-through data with your key manufacturers. When they see your stock increasing in real-time, they can begin staging raw materials (like fabric or components) for a rapid re-order.

Fulfillment Optimization

Implement dynamic slotting in your warehouse to find the needed items as quick as possible. Specifically, thirty days before a peak, move seasonal "hot" items to the front of the warehouse (closest to packing stations) to reduce pick-times.

Besdies, implement omnichannel inventory integration to make fulfillment process much faster. Use your physical stores as mini-distribution centers (Ship-from-Store) to move seasonal stock faster and reduce localized overstock.

>> Let's consider: 7 Best Omni Channel Inventory Management Software Solutions

Sales & Marketing Coordination

Make sure your Sales and Marketing teams coordinate smoothly in launches and promotions with stock readiness. Let's use an Inventory Management System (IMS) or ERP that provides a single source of truth across all sales channels.

Always ensure digital ads automatically pause if an item’s stock level drops below a certain threshold to avoid wasting ad spend on out-of-stock items.

Markdown & Clearance Optimization

The goal of seasonal inventory is to have zero units left at the end of the window. So, take first with dynamic pricing models like markdown ladder. For example, instead of a massive "Fire Sale" at the end of the season, take 15% "Mid-Season" discount on slow-moving SKUs to stimulate velocity. It is more profitable than taking a 60% "Clearance" hit once the season has already ended.

Another tips is that holding a cross-functional review within 14 days of a season’s end. Document exactly why certain items failed (Was it the price? The fit? The late delivery?) to ensure the same mistake doesn't repeat in the next year’s forecast.

Seasonal Inventory Management Strategies

FAQs

What are factors influencing seasonal demand?

Seasonal demand in fashion is shaped by multiple overlapping factors:

Weather and Climate: Temperature shifts, unexpected heatwaves, delayed winters, or extended summers can significantly alter buying behaviour.

Holidays and Cultural Events: Festivals, weddings, school calendars, and regional holidays directly impact category-specific demand.

Social Trends and Influencers: Virality on social platforms can compress a season into weeks instead of months.

Economic Conditions: Inflation, consumer confidence, and discretionary spending influence how much customers buy, even in peak seasons.

Marketing and Promotions: Campaign timing can either amplify demand or shift it earlier or later in the season.

Shelf Life and Perishability: Fashion inventory “expires” stylistically, not physically, but loses value just as quickly.

What qualifies as seasonal inventory?

Any product with demand concentrated in a specific time window and limited relevance outside that period is considered seasonal inventory.

How do you calculate seasonal demand?

Seasonal demand is calculated by analyzing:

Historical sales patterns

Seasonality indexes (year-over-year, month-over-month trends)

External factors such as weather, holidays, and major events

The goal is to separate true seasonal demand from one-time spikes.

How does seasonality affect safety stock?

Seasonal demand usually comes with higher variability, which often requires higher safety stock. However, this need can be reduced when forecasting accuracy improves, either through better data or shorter lead times.

How do AI and machine learning predict seasonal demand?

AI and machine learning models identify:

Non-linear demand patterns

Sudden trend shifts

External signals like weather, events, and online activity

These signals are often missed by traditional forecasting methods.

How often should seasonal plans be updated?

Here is an ideal frequency for updating seasonal plans:

Weekly during the active season;

Monthly in the pre-season planning phase;

Post-season for long-term learning and improvement.

How Nūl Helps You Manage Seasonal Inventory?

Nūl helps fashion brands manage seasonal inventory by combining SKU-level intelligence, forecasting, and decision automation.

Instead of static seasonal plans, Nūl:

Forecasts demand by season phase, SKU, and channel;

Monitors in-season performance in real time;

Flags risk early like overstock, stockouts, or slow movers;

Supports proactive pricing, allocation, and replenishment decisions.

This allows teams to move from reactive seasonal firefighting to structured, repeatable seasonal planning.

Conclusion

Seasonal inventory management is no longer about guessing demand and reacting late.

In today’s fashion landscape, winning brands:

Plan seasonality with data;

Monitor performance continuously;

Act early, not at clearance time;

Treat each season as a learning cycle.

With the right strategy, tools, and discipline, seasonal inventory can shift from being a financial risk to a competitive advantage.

Article by

Nūl Content Team

An Experienced Research & Knowledge Team

The Nūl Content Team combines expertise in technology, fashion, and supply chain management to deliver clear, practical insights. Guided by Nūl’s mission to end overproduction, we create content that helps brands forecast demand more accurately, optimize inventory, and build sustainable operations. Every piece we publish is grounded in real-world experience, ensuring it’s both credible and actionable.

LinkedIn Profile

More From Blog

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

More From Blog

A Practical Guide to Manage Inventory for Seasonal Products

Dec 25, 2025

Seasonal inventory management is the strategic process of forecasting, planning, buying, allocating, and managing stock to match predictable demand spikes.

Seasonality has always shaped the fashion industry, but in 2026, it matters more than ever. Weather volatility, shorter trend cycles, influencer-driven demand spikes, and tighter cash flow conditions mean that getting seasonal inventory wrong is more expensive than ever. A single forecasting mistake can lead to excess stock, heavy markdowns, or missed sales during peak demand.

Fashion brands frequently experience:

Overstocked end-of-season inventory that ties up cash;

Stockouts during peak weeks;

Poor sell-through due to mistimed buying;

Margin erosion from reactive discounting.

But, there are still brands that manage seasonal inventory well and outperform peers with higher sell-through, healthier cash flow, and more predictable operations. What are the tips? In this blog, we guide you through seasonal inventory management, how to manage them, and best strategies for your future success.

What Is Seasonal Inventory Management?

Seasonal inventory management is the strategic process of forecasting, planning, buying, allocating, and managing stock to match predictable demand spikes due to weather, holidays, or events.

In fashion, this includes products that:

Peak for a limited window;

Decline rapidly after the season ends;

Lose value quickly if demand timing is missed.

It focuses on having enough inventory to meet peak-season demand without overstocking, using data, AI/analytics, and flexible supply chains to track real-time changes, adjust procurement, and plan efficient clearance after the season.

The goal is to maximize profit during high-demand periods, prevent stockouts, and minimize losses from excess inventory once demand falls.

Some seasonal inventory examples in fashion:

Swimwear & resortwear → Spring / Summer, closely tied to weather and travel seasons.

Coats, knitwear, thermals → Fall / Winter, with short selling windows in colder regions.

Festive & holiday dresses → October–December, driven by year-end events and celebrations.

Occasionwear → Wedding seasons, festive calendars, which vary by region and culture.

Back-to-school apparel → Regional academic cycles, often with sharp demand spikes before term starts.

Unlike evergreen basics, seasonal inventory has high timing sensitivity, selling late often means selling at a loss.

4 Common Types of Seasonal Demand in Fashion

Event / Holiday Demand

This type of demand is the most predictable because the calendar provides clear signals. Specific occasions such as weddings, festivals, or year-end celebrations usually happen at the same time each year. In this demand type, sales rise sharply within a short window and fall quickly once the event ends. You need to make timing and stock depth exact.

Examples: Lunar New Year, Black Friday /Cyber Monday, wedding seasons, graduation periods.

Strategy: This demand requires backward scheduling. This means working back from the event date to calculate when inventory must arrive in stores. In most cases, stock needs to be available 4–6 weeks before the event to capture early demand and avoid last-minute shortages.

Weather-Driven Demand

Unlike holidays, weather demand is more volatile. It rises or falls based on temperature and climate conditions. Because weather patterns shift each year due to global climate changes, this demand is increasingly harder to predict and need adjustments in season.

Examples: A warm winter leads to an overstock of heavy parkas, unseasonable heatwaves in Spring drives early sandal sales.

Strategy: Implement demand sensing technology to adjust replenishment based on short-term weather forecasts rather than just historical averages.

Cultural / Geographic Demand

Seasonality varies by region and culture, so using a single global calendar cannot meet demand in every market. For example, winter in Australia happens at a different time than in Europe or North America, so how can you sell the same seasonal products across those regions? Thus, brands selling globally must plan inventory by market, not by a single global season.

Examples: Winter in the Northern Hemisphere is Summer in the Southern, Linen shirts can be wore everyday in hot climates, but are only popular during summer holidays in colder regions.

Strategy: Apply localized assortment planning. Avoid "pushed" inventory from headquarters, instead, "pull" inventory based on regional climate and cultural relevance (e.g., specific colors for regional festivals).

>> You can consider: 10 Best Assortment Planning Software for Fashion Brands

Promotional Demand

This demand is intentionally created by the marketing department, not by the external environment. Through planned sales, product launches, or influencer drops, brands can create short-term demand spikes. Although this demand type is predictable on the calendar, it still carry risk if marketing response is weaker or stronger than expected.

Examples: Limited-edition drops, influencer collaborations, or mid-season flash sales.

Strategy: Close synchronization between Marketing and Supply Chain. The "Bullwhip Effect" is most dangerous here, where a small spike in promotional demand leads to massive over-ordering if not communicated clearly.

Common Types of Seasonal Demand in Fashion

Benefits of Effective Seasonal Inventory Management

Maximizes Revenue: Having the right products in the right place at the right time means brands can capture the highest possible volume of transactions during the narrow window of consumer intent.

Improves Profitability: Better planning leads to higher full-price sell-through and fewer last-minute markdowns. Every item sold at the start of the season at MSRP is worth significantly more than two items sold at a 50% discount during clearance.

Enhances Customer Satisfaction: Nothing damages customer retention like stockout during a peak shopping moment (e.g., no winter coats in stock during a December cold snap). Besides increased brand loyalty, there are no backorders and lost sales during peak periods as well.

Optimizes Working Capital: Reducing Days Sales of Inventory (DSI) means working capital isn't tied up in unsold end-of-season stock. This liquidity allows the business to reinvest in new collections or core product for the next season.

Reduces Losses: Optimized stock levels reduce holding costs including warehouse labor, insurance, and the physical space required for aged inventory. Also, there are fewer forced liquidation decisions at the end of the season.

>> Explore further tips: 16 Best Cost Reduction Strategies in Inventory Management

Practical Guide: How to Manage Inventory for Seasonal Products?

1. Identify Seasonal Products

Clearly separate your evergreen basics (sold year-round) from your seasonal items. Also, there are different types in seasonal products like:

Pure Seasonal: Items with zero demand outside the window (e.g., Christmas ornaments).

Seasonal Peak: Evergreen items that see a 5x-10x spike (e.g., white t-shirts during Back-to-School).

Trend Seasonal: Fashion items that are both seasonal and high-risk due to short-lived styles or trends that may not repeat next year.

Tip: Tag seasonal items in your ERP/IMS with specific "Season Tags" to prevent automated replenishment systems from ordering them during the off-season.

2. Analyze Past Seasonal Performance

Start by reviewing last season’s results to understand where money was lost, not just what sold. Then, you can adjust next season’s buys, timing, and pricing strategy based on what actually happened.

Stockout Analysis: Identify products that sold out too early. For example, If you sold out of a parka in November, how much revenue did you leave on the table in December?

Markdown Depth: Review how much discounting was needed to clear inventory. Did you achieve a 70% sell-through at full price, or was your profit eaten by forced 50% discounts?

Key KPIs to measure seasonal inventory performance:

Sell-through rate (%);

Markdown depth (how much did you have to discount to move it?);

Stockout timing (did you run out before the peak?);

Inventory Turnover;

Days to Sell Inventory (DSI);

Average Inventory Levels;

Stockout Rate;

Rate of Return;

Backorder Rate.

3. Build a Seasonal Demand Forecast

Forecast demand by:

Season phase (early, peak, late)

Channel (online, retail, wholesale): E-commerce usually peaks earlier (shipping lead times) than physical retail (last-minute shoppers).

Location or region: Winter demand for boots hits Minneapolis three weeks before it hits Seattle.

This gives you a more realistic view than using one total forecast.

4. Align Forecast With Supplier Lead Times

Negotiate fabric or raw component holding with your suppliers. Instead of finishing the full product upfront, have suppliers hold base materials and delay final production until demand becomes clearer.

You know, long supplier lead times increase risk in seasonal inventory. When production takes too long, decisions must be made before real demand is visible, leaving little room to adjust.

If this is agreed, you can:

Commit early to raw materials;

Delay style, color, or size decisions;

Shorten final production and shipping.

5. Plan Inventory Levels by Season Phases

Avoid front-loading that ships 100% of your stock to stores on Day 1. Instead, deploy 40-50% of your inventory for launch to fill the floor/site. Hold the remaining 50% at a central Distribution Center (DC) to replenish the specific locations or sizes that are selling fastest.

6. Allocate Inventory Across Channels and Locations

Use a centralized push-pull system to allocate stock to high-velocity locations while holding back a safety pool in a central warehouse. Allocation can be based on store grading:

Tier 1 Stores: Receive the full depth and breadth of the collection.

Tier 3 Stores: Receive only best-seller items to minimize the risk of fragmented, unsold stock.

>> Read more: What is Inventory Velocity? Formula, Example, & Best Practices

7. Monitor In-Season Performance

During the peak, track Sales Velocity and Weeks of Cover (WOC) weekly. Monthly reports are useless at this time. Some metrics you have to follow:

Sell-Through Rate (STR): (Units Sold / Units Received) × 100.

Weeks of Cover (WOC): Current On-Hand Stock ÷ Average Weekly Sales. If your WOC is higher than the remaining weeks in the season, you have an overstock problem.

Example: If you have 500 units and sell 100/week, you have 5 WOC. If the season ends in 3 weeks, you are overstocked.

8. Adjust Prices and Promotions

Use promotions or markdown strategies to reshape demand, not just react to failure. You can use short-term 10-15% discounts on slow-moving colors or sizes early in the season to re-balance the stock before it becomes dead stock.

Don’t hesitate too long out of fear of hurting your brand or margin. If sales velocity is already slow in week three, a small, controlled 10% flash sale can prevent a 50% clearance sale in week eight.

9. Manage Returns and Reverse Logistics

Prioritize the put-away of seasonal returns over evergreen items. In fact, seasonal products often see higher return rates because they are bought earlier than they are actually used and are tied to short selling windows. As a result, post-season and post-holiday returns can account for 15–30% of seasonal volume. The real risk is time.

Thus, try to inspect fastly and re-enter these products to inventory while demand still exists. As a result, you can maximize full-price recovery and reduce forced markdowns.

10. Execute Rapid Liquidation

Move unsold stock to outlet channels, end-of-season bundles, or third-party liquidators immediately to free up cash for the next season.

You know, once the season is over, the item is no longer an asset, it is a liability taking up space. Every day an item sits on the shelf, it costs you money in opportunity cost.

11. Run a Post-Season Review

Document what worked, what didn’t, and why, like:

What were the "Hero" products?

Where did the forecast fail?

Which suppliers met their lead time?

This is the most skipped step, yet it delivers the highest long-term value. Without a structured post-season review, the same forecasting errors, supplier issues, and allocation mistakes are repeated year after year.

Seasonal Inventory Management Strategies for Fashion Brands

Data-Driven Forecasting

Use historical sales, seasonality patterns, market signals, and even macroeconomic indicators to predict demand by product, location, and time period. Also, use demand sensing backed by AI/ML technology to identify near-term trends. With real-time data like weather patterns or social media spikes, you can adjust inventory levels mid-season, long before a traditional forecast would react.

>> Read more:

14 Best Demand Forecasting Methods in Fashion Supply Chain

Pre-Season Capacity Planning

Prepare warehouse space, labor, and logistics capacity before peak demand begins. Let's identify "bottleneck" periods. If your forecast shows a 300% increase in volume for November, you may need to secure temporary overflow warehousing or 3PL (Third-Party Logistics) support months in advance.

Technology Adoption

Use inventory automation systems, demand forecasting tools, and real-time inventory visibility across all channels. You know, manual spreadsheets are the primary cause of seasonal overstock. Let's use modern systems driven by AI to suggest reorder points based on velocity and automate other tasks.

Agile Supply Chain

Always align your buying volumes with your forecast confidence and manufacturer lead times. Instead of one massive, high-risk pre-season order, negotiate phased deliveries. Commit to a base volume but keep a percentage of your budget "Open-to-Buy" (OTB) to react to winners.

You can also share your real-time sell-through data with your key manufacturers. When they see your stock increasing in real-time, they can begin staging raw materials (like fabric or components) for a rapid re-order.

Fulfillment Optimization

Implement dynamic slotting in your warehouse to find the needed items as quick as possible. Specifically, thirty days before a peak, move seasonal "hot" items to the front of the warehouse (closest to packing stations) to reduce pick-times.

Besdies, implement omnichannel inventory integration to make fulfillment process much faster. Use your physical stores as mini-distribution centers (Ship-from-Store) to move seasonal stock faster and reduce localized overstock.

>> Let's consider: 7 Best Omni Channel Inventory Management Software Solutions

Sales & Marketing Coordination

Make sure your Sales and Marketing teams coordinate smoothly in launches and promotions with stock readiness. Let's use an Inventory Management System (IMS) or ERP that provides a single source of truth across all sales channels.

Always ensure digital ads automatically pause if an item’s stock level drops below a certain threshold to avoid wasting ad spend on out-of-stock items.

Markdown & Clearance Optimization

The goal of seasonal inventory is to have zero units left at the end of the window. So, take first with dynamic pricing models like markdown ladder. For example, instead of a massive "Fire Sale" at the end of the season, take 15% "Mid-Season" discount on slow-moving SKUs to stimulate velocity. It is more profitable than taking a 60% "Clearance" hit once the season has already ended.

Another tips is that holding a cross-functional review within 14 days of a season’s end. Document exactly why certain items failed (Was it the price? The fit? The late delivery?) to ensure the same mistake doesn't repeat in the next year’s forecast.

Seasonal Inventory Management Strategies

FAQs

What are factors influencing seasonal demand?

Seasonal demand in fashion is shaped by multiple overlapping factors:

Weather and Climate: Temperature shifts, unexpected heatwaves, delayed winters, or extended summers can significantly alter buying behaviour.

Holidays and Cultural Events: Festivals, weddings, school calendars, and regional holidays directly impact category-specific demand.

Social Trends and Influencers: Virality on social platforms can compress a season into weeks instead of months.

Economic Conditions: Inflation, consumer confidence, and discretionary spending influence how much customers buy, even in peak seasons.

Marketing and Promotions: Campaign timing can either amplify demand or shift it earlier or later in the season.

Shelf Life and Perishability: Fashion inventory “expires” stylistically, not physically, but loses value just as quickly.

What qualifies as seasonal inventory?

Any product with demand concentrated in a specific time window and limited relevance outside that period is considered seasonal inventory.

How do you calculate seasonal demand?

Seasonal demand is calculated by analyzing:

Historical sales patterns

Seasonality indexes (year-over-year, month-over-month trends)

External factors such as weather, holidays, and major events

The goal is to separate true seasonal demand from one-time spikes.

How does seasonality affect safety stock?

Seasonal demand usually comes with higher variability, which often requires higher safety stock. However, this need can be reduced when forecasting accuracy improves, either through better data or shorter lead times.

How do AI and machine learning predict seasonal demand?

AI and machine learning models identify:

Non-linear demand patterns

Sudden trend shifts

External signals like weather, events, and online activity

These signals are often missed by traditional forecasting methods.

How often should seasonal plans be updated?

Here is an ideal frequency for updating seasonal plans:

Weekly during the active season;

Monthly in the pre-season planning phase;

Post-season for long-term learning and improvement.

How Nūl Helps You Manage Seasonal Inventory?

Nūl helps fashion brands manage seasonal inventory by combining SKU-level intelligence, forecasting, and decision automation.

Instead of static seasonal plans, Nūl:

Forecasts demand by season phase, SKU, and channel;

Monitors in-season performance in real time;

Flags risk early like overstock, stockouts, or slow movers;

Supports proactive pricing, allocation, and replenishment decisions.

This allows teams to move from reactive seasonal firefighting to structured, repeatable seasonal planning.

Conclusion

Seasonal inventory management is no longer about guessing demand and reacting late.

In today’s fashion landscape, winning brands:

Plan seasonality with data;

Monitor performance continuously;

Act early, not at clearance time;

Treat each season as a learning cycle.

With the right strategy, tools, and discipline, seasonal inventory can shift from being a financial risk to a competitive advantage.

Article by

Nūl Content Team

An Experienced Research & Knowledge Team

An Experienced Research & Knowledge Team

The Nūl Content Team combines expertise in technology, fashion, and supply chain management to deliver clear, practical insights. Guided by Nūl’s mission to end overproduction, we create content that helps brands forecast demand more accurately, optimize inventory, and build sustainable operations. Every piece we publish is grounded in real-world experience, ensuring it’s both credible and actionable.

LinkedIn Profile