What is Demand Sensing? Benefits, How it Works, Implementation

Dec 19, 2025

Demand sensing is an AI-driven forecasting approach that predicts short-term demand using real-time, granular data such as POS sales, weather, social media, etc.

Fashion demand has never been more volatile. Seasons are shorter, trends spread overnight on social sites like TikTok, and global supply chains face constant disruption. For most brands, traditional forecasting methods built on last year’s sales and fixed seasonal assumptions are no longer reliable.

This is where demand sensing becomes essential. Demand sensing is a more optimal solution that can solve your demand forecasting issues in fashion. In this guide, we’ll break down what demand sensing is, how it works, when it makes sense to use it, and how you can start implementing it in your own supply chain.

>> You can consider: Perpetual vs Periodic Inventory System: What's the Difference?

What is Demand Sensing?

Demand sensing is an AI-driven approach that predicts short-term demand using real-time, granular data such as POS sales, inventory movements, social media, weather patterns, and promotional calendars. Unlike traditional forecasting (which looks months ahead), demand sensing focuses on the next few days to 8 weeks, giving brands the ability to react fast to changes in customer behaviour.

Example: A brand notices on Monday that a specific dress starts trending on Instagram in Sydney. Demand sensing identifies a sudden spike in online searches, warm weather forecasts, and increased conversion. By Tuesday, the system increases allocation to the Sydney store and triggers a replenishment order to avoid stockouts later that week.

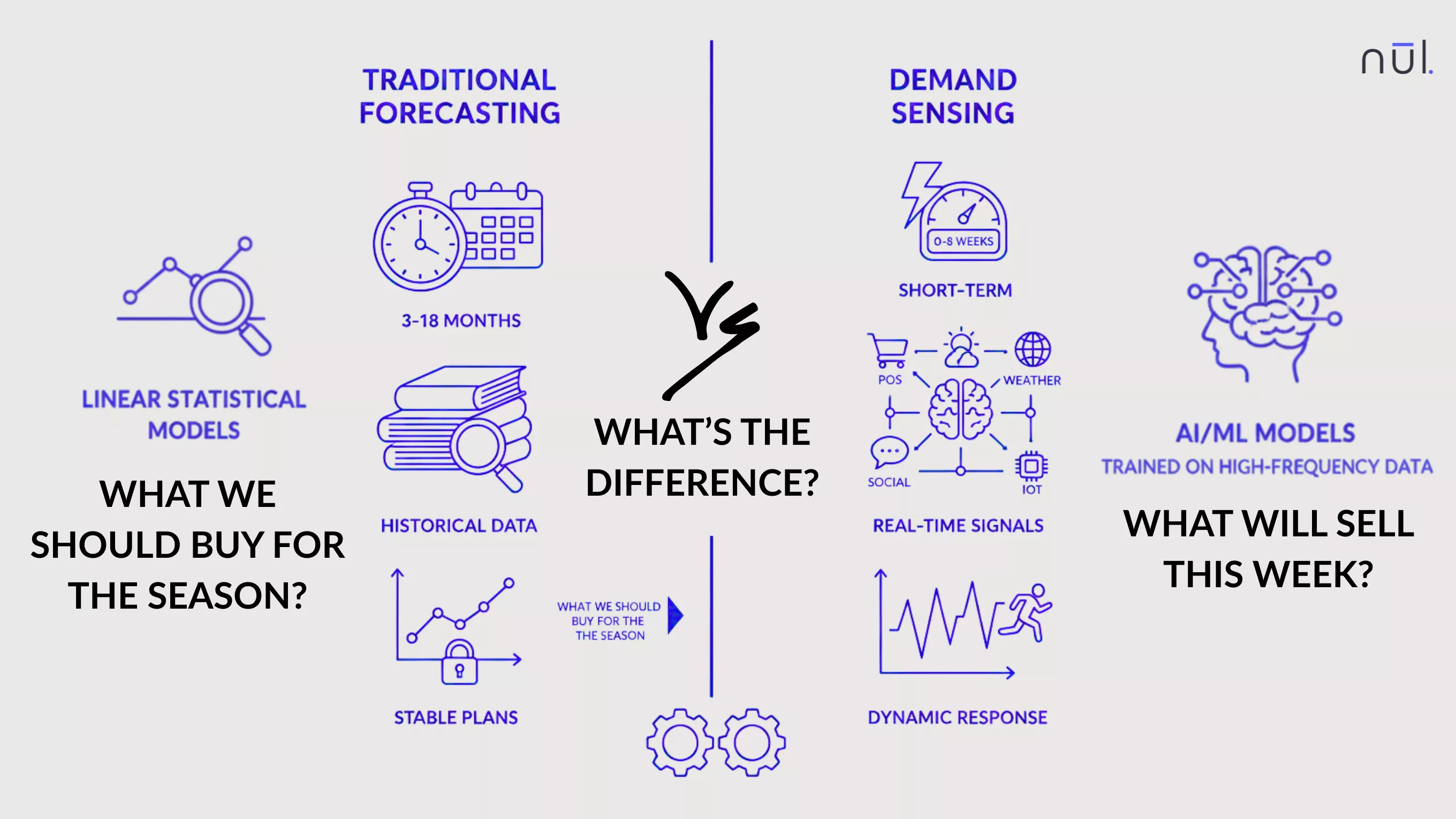

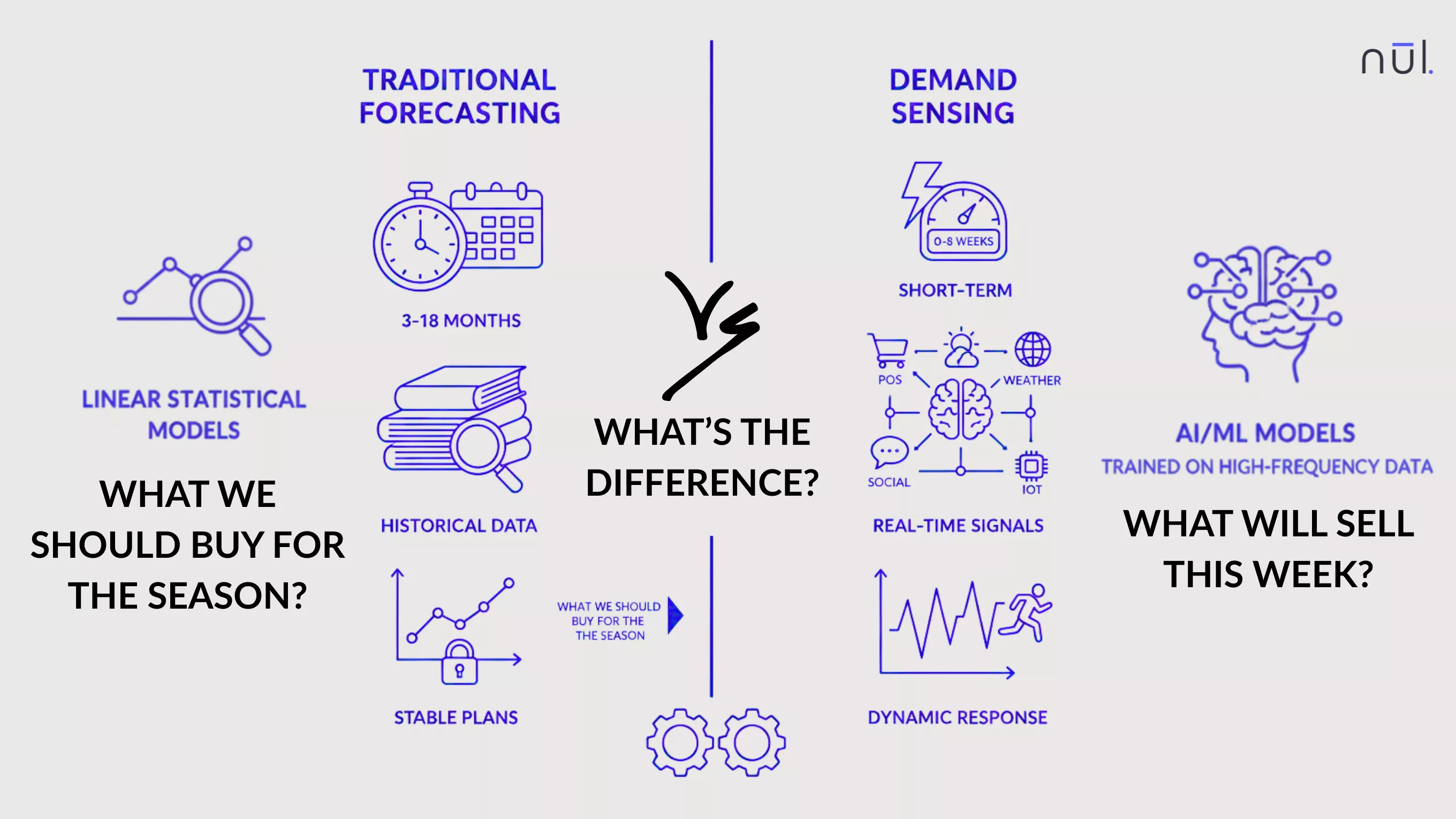

Demand Sensing vs Traditional Demand Forecasting: What’s the Difference?

While traditional forecasting focuses on "what we should buy for the season," demand sensing answers "what will sell this week" by capturing sudden shifts in consumer behavior before they appear in historical reports.

Category | Traditional Forecasting | Demand Sensing |

|---|---|---|

Objective | Long-term seasonal plans | Short-term responsiveness |

Time Horizon | 3 – 18 months | 0 – 8 weeks |

Data Sources | Historical sales | Real-time signals: POS, weather, social, events, IoT, and web searches. |

Update Frequency | Quarterly/monthly/weekly | Daily or intraday |

Technology | Linear statistical models | AI/ML models trained on high-frequency data |

Outcome | Stable, strategic forecast | Dynamic, responsive forecast |

Demand Sensing vs Traditional Demand Forecasting: What’s the Difference?

What Are the Benefits of Demand Sensing?

Reduced Forecast Errors

By analyzing real-time causal factors, sensing can reduce short-term forecast errors by 20% to 50% (according to McKinsey & Company). Teams can identify "black swan" events, such as a product going viral on social media, allowing for stock adjustments within days rather than weeks. It also improves near-term forecast accuracy so you face fewer stockouts, overstocks, and markdowns strategies.

Lower Supply Chain Costs

Enhanced accuracy can reduce safety stock levels without risking service levels, which directly reduce your storage costs. Besides, more accurate predictions minimize the need for high-cost "emergency" measures like expedited air shipping or last-minute warehouse labor adjustments.

>> Read more: 16 Best Cost Reduction Strategies in Inventory Management

Increased Sales

Automated systems recommend or trigger inventory moves so the right products are allocated to the right channel/store at the right time. This directly improve on-shelf availability and customer loyalty because shelves are always stocked during peak periods and shoppers can get what they need without waiting too long.

During promotions, they also track live sales against the expected uplift in each region or channel and adjust the short-term forecast accordingly. This helps planners top up hot spots, reallocate stock from weaker areas, and avoid both empty shelves and wasted inventory.

Better Operational Decisions

AI-powered demand forecasting platforms automatically collect and process all the signals, so planners spend more time focusing on high-value tasks. These systems then deliver timely, data-driven alerts and recommendations, allowing teams to adjust plans proactively instead of reacting late.

Modern solutions also use Explainable AI (XAI) to show why a forecast changed (for example, “5% increase due to a local sporting event”), which builds trust between planners and the technology.

More Sustainable Operations

The fashion industry cause an estimated 2 million tonnes of textile waste, and one of its biggest causes is inaccurate forecasts. Demand sensing ensures that stock is not pushed to locations where it will sit idle, eventually requiring deep markdowns or ending up in landfills.

Demand sensing helps cut this waste by slowing or stopping production as soon as a trend cools and improving raw material management so that brands don’t commit to fabric and components they won’t use. It also makes sure inventory goes to stores and channels where it will actually sell, not sit idle and end up in landfills.

This reduction in garments overproduction and unsold stock lowers the carbon footprint of the supply chain. Brands also have stronger, data-backed evidence for their ESG (Environmental, Social, and Governance) reporting on waste, emissions, and responsible resource use.

>> You may need: Top 8 Best Raw Material Inventory Management Software

Benefits of Demand Sensing

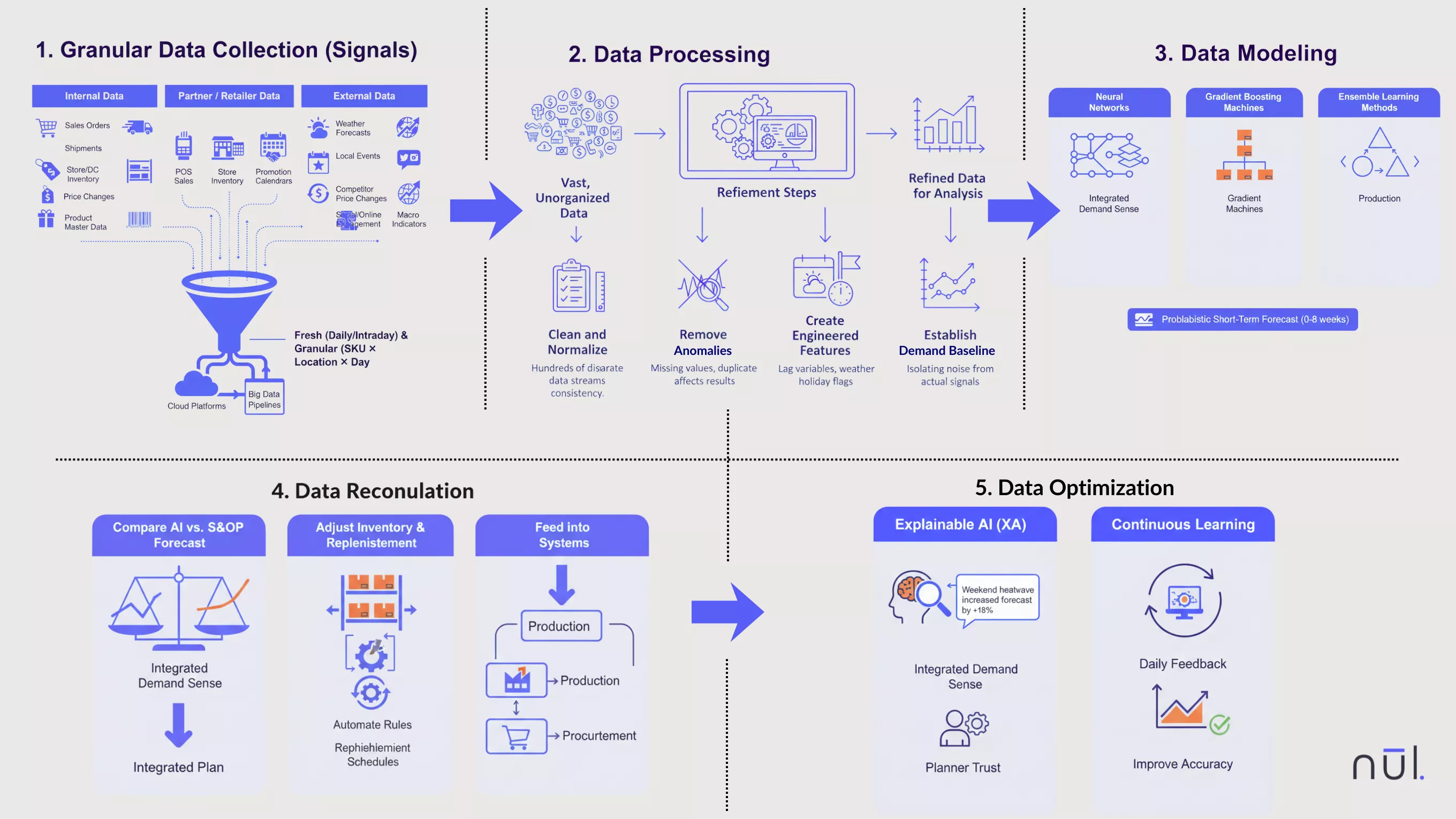

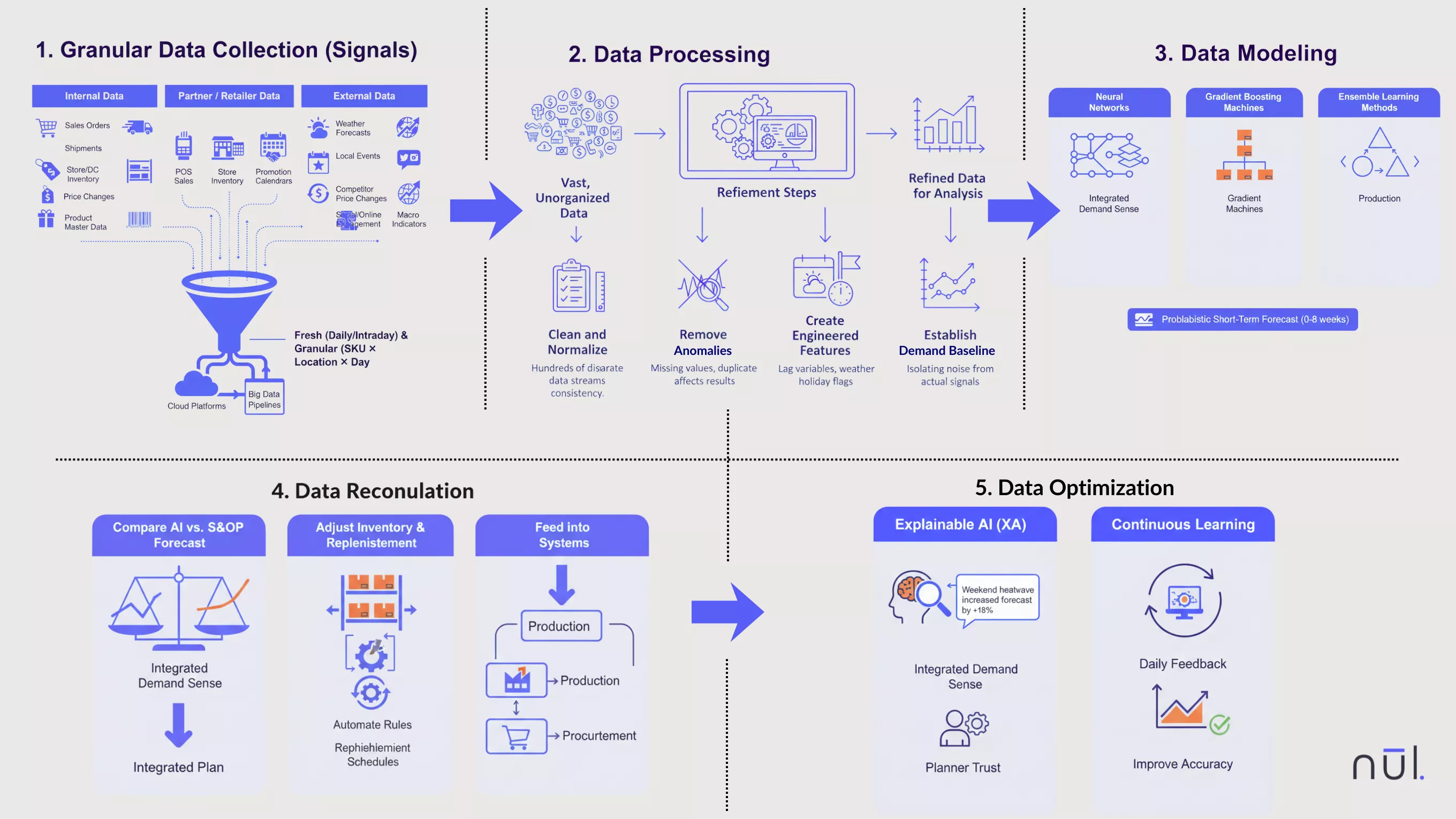

How Does Demand Sensing Work?

Demand sensing is built on a structured, data-driven process. Here’s the full workflow:

1. Granular Data Collection (Signals)

Demand sensing collects high-frequency signals from multiple sources to identify current market trends::

Internal Data:

Sales orders;

Shipments;

Store/DC inventory;

Price changes;

Promotions;

Product master data.

Partner / Retailer Data:

POS sales;

Store inventory;

Supplier/retailer promotion calendars.

External Data:

Weather forecasts;

Local events;

Competitor price changes;

Social/online engagement signals;

Macro indicators.

Note: Signals must be fresh (daily or intraday) and granular (SKU × location × day). Modern demand sensing requires big data pipelines and cloud platforms to handle volume and velocity.

2. Data Processing

Once signals are collected, the system prepares vast, unorganized data for analysis through several refinement steps:

Clean and normalize hundreds of disparate data streams to ensure consistency across sources;

Remove anomalies, missing values, duplicate entries that can affect results;

Create engineered features (lag variables, weather impact, holiday flags);

Establish a baseline for true underlying demand by isolating noise from actual signals.

3. Data Modeling

Demand sensing uses non-linear machine learning models to capture complex, non-obvious patterns, such as:

Neural Networks: Effectively models sequential historical patterns and non-linear relationships.

Gradient Boosting Machines: Such as XGBoost, which are ideal for handling high-dimensional data with multiple external factors.

Ensemble Learning Methods: Combine multiple models to generate more reliable results.

The output is a probabilistic short-term forecast with confidence intervals for the next 0–8 weeks.

4. Data Reconciliation

The refined short-term forecast is integrated into broader business planning to ensure operational alignment:

Compare the AI-driven short-term “sense” against the long-term strategic S&OP forecast.

Automatically adjust inventory and replenishment rules to meet the sensed demand.

Feed updated demand into allocation, production, and procurement systems for immediate action.

>> You can consider: 10 Best Inventory Replenishment Software Solutions

5. Data Optimization

To build planner trust, advanced systems use:

Explainable AI (XAI): Explains why the forecast changed (e.g., “Weekend heatwave increased forecast by +18%”) to build planner trust.

Continuous Learning: Actual sales data is fed back into the model daily to retrain the algorithm and improve accuracy over time.

How Does Demand Sensing Work?

How to Implement Demand Sensing for Your Fashion Brand?

Successful adoption requires a structured rollout. Here’s a practical roadmap:

1. Define Scope & KPIs

Identify 3–5 high-value business outcomes to measure the success of the implementation:

Reduce stockouts by 20%: Improving on-shelf availability directly captures lost revenue.

Improve full-price sell-through by 10%: Better accuracy reduces the need for deep clearance markdowns.

Cut replenishment errors by 30%: Ensuring the right SKU is in the right location minimizes costly cross-region transfers.

Reduce aged inventory: Preventing overproduction limits the accumulation of dead stock that eventually ends up in landfills.

2. Audit Data Readiness

Demand sensing is only as effective as the data it consumes, requiring an audit of your current digital infrastructure:

Completeness of sales and inventory data: Ensure daily data flows are available for both physical and online channels.

Accessibility of external signals (POS, weather, competitor data): Verify the ability to ingest POS, weather, and competitor data via APIs or partner portals.

Data governance (cleaning rules, naming conventions): Establish strict cleaning rules and naming conventions to harmonize disparate data streams.

3. Select the Right Platform

Your demand sensing tool must include these four essential capabilities:

Ingest any internal/external data source (POS, ERP, PLM, Shopify, weather APIs).

Granular visibility at SKU × store/channel level.

Unified ML/AI engine across sensing, planning, replenishment, and pricing.

Native integration with downstream supply processes like replenishment, allocation, and production scheduling.

4. Pilot on a High-Value Product Line

To build planner buy-in and demonstrate ROI, launch a pilot program on a carefully selected category. Consider a category with::

High volatility: Choose products where demand shifts rapidly, making them difficult to forecast traditionally.

High revenue impact: Select a core category where improvements significantly affect the bottom line.

Frequent replenishment: Focus on items with short lead times where sensing can trigger immediate stock adjustments.

This delivers early wins and planner buy-in.

5. Integrate and Automate

Automation is key to reducing latency that is the time between sensing a shift and responding to it. Connect sensing signals directly to:

Replenishment logic: Automatically update target stock levels in stores based on daily sensed demand.

Production scheduling: Signal factories to adjust short-cycle manufacturing runs to match current sales trends.

Allocation engines: Re-route incoming shipments to locations with the highest predicted sell-through.

6. Continuous Performance Monitoring

Track metrics like:

Forecast Value Add (FVA): Measuring how much the sensing model improves accuracy over the traditional statistical baseline.

Stockouts and overstock rates: Monitoring the reduction in both lost sales and excess inventory.

Weeks of supply: Tracking improvements in inventory turnover.

Sell-through %: Confirming that more products are selling at full price as a result of better allocation.

Use results to refine models and improve ROI.

FAQs

1. What is the underlying demand sensing technology?

The core demand sensing technology are AI/ML models, especially neural networks and gradient boosting, that can process real-time signals to generate a short-term forecast. This tech stack requires big data pipelines and cloud-native platforms to handle volume and velocity of granular data.

2. How does demand sensing differ from demand planning?

Demand Planning focuses on the long-term and strategic (3–18 months), establishing baselines for budgeting and capacity planning.

Demand Sensing: Focuses on the short-term and reactive (0–8 weeks), adjusting forecasts daily or even intraday based on fresh market signals to improve immediate actions.

3. What are the three types of predictive models?

Machine learning models (e.g., XGBoost)

Deep learning models (e.g., LSTMs)

Hybrid ensemble models

4. Which tools support real-time demand sensing?

Leading solutions include:

AI-Driven Demand Sensing and Trend Forecasting: Nūl, Heuritech, Stylumia, EDITED, Nextail, Trendalytics, WGSN, Singuli, Syrup Tech, Designove

Enterprise Platforms: o9 Solutions, Blue Yonder, Antuit.ai, and ToolsGroup.

Native ERP Add-ons: Modules such as SAP IBP for Demand that integrate directly with core transactional data.

5. Who offers real-time demand sensing capabilities?

Next-generation planning and agentic AI platforms can offer real-time demand sensing capabilities. They can process intraday data, integrate external signals, and automatically update inventory decisions.

How Nūl Supports Demand Sensing?

Nūl’s agentic AI platform brings demand sensing directly into daily workflows for fashion operators:

Real-time multi-source data ingestion (Shopify, weather, social signals, returns, store stock).

AI-driven short-term forecasting at SKU × location × day granularity.

Explainable AI recommendations so teams understand why demand changed.

Native integration with replenishment, allocation, pricing, and materials planning, enabling rapid operational action.

Continuous learning loops that update models weekly or daily based on sell-through performance.

Nūl helps brands move from reactive planning to a proactive, predictive operating model.

Conclusion

Demand sensing is quickly becoming a competitive necessity in the fashion supply chain. With real-time data and AI-driven predictions, brands can reduce waste, increase full-price sell-through, prevent stockouts, and respond instantly to changing customer behaviour.

As trends accelerate and uncertainty becomes the norm, demand sensing gives brands the agility and intelligence needed to thrive.

Article by

Nūl Content Team

An Experienced Research & Knowledge Team

The Nūl Content Team combines expertise in technology, fashion, and supply chain management to deliver clear, practical insights. Guided by Nūl’s mission to end overproduction, we create content that helps brands forecast demand more accurately, optimize inventory, and build sustainable operations. Every piece we publish is grounded in real-world experience, ensuring it’s both credible and actionable.

LinkedIn Profile

More From Blog

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

Co-Build With Us

We are so keen to get this right. If the problem statement resonates, please reach out and we’d love to co-build with you so fits right into your existing workflow.

More From Blog

What is Demand Sensing? Benefits, How it Works, Implementation

Dec 19, 2025

Demand sensing is an AI-driven forecasting approach that predicts short-term demand using real-time, granular data such as POS sales, weather, social media, etc.

Fashion demand has never been more volatile. Seasons are shorter, trends spread overnight on social sites like TikTok, and global supply chains face constant disruption. For most brands, traditional forecasting methods built on last year’s sales and fixed seasonal assumptions are no longer reliable.

This is where demand sensing becomes essential. Demand sensing is a more optimal solution that can solve your demand forecasting issues in fashion. In this guide, we’ll break down what demand sensing is, how it works, when it makes sense to use it, and how you can start implementing it in your own supply chain.

>> You can consider: Perpetual vs Periodic Inventory System: What's the Difference?

What is Demand Sensing?

Demand sensing is an AI-driven approach that predicts short-term demand using real-time, granular data such as POS sales, inventory movements, social media, weather patterns, and promotional calendars. Unlike traditional forecasting (which looks months ahead), demand sensing focuses on the next few days to 8 weeks, giving brands the ability to react fast to changes in customer behaviour.

Example: A brand notices on Monday that a specific dress starts trending on Instagram in Sydney. Demand sensing identifies a sudden spike in online searches, warm weather forecasts, and increased conversion. By Tuesday, the system increases allocation to the Sydney store and triggers a replenishment order to avoid stockouts later that week.

Demand Sensing vs Traditional Demand Forecasting: What’s the Difference?

While traditional forecasting focuses on "what we should buy for the season," demand sensing answers "what will sell this week" by capturing sudden shifts in consumer behavior before they appear in historical reports.

Category | Traditional Forecasting | Demand Sensing |

|---|---|---|

Objective | Long-term seasonal plans | Short-term responsiveness |

Time Horizon | 3 – 18 months | 0 – 8 weeks |

Data Sources | Historical sales | Real-time signals: POS, weather, social, events, IoT, and web searches. |

Update Frequency | Quarterly/monthly/weekly | Daily or intraday |

Technology | Linear statistical models | AI/ML models trained on high-frequency data |

Outcome | Stable, strategic forecast | Dynamic, responsive forecast |

Demand Sensing vs Traditional Demand Forecasting: What’s the Difference?

What Are the Benefits of Demand Sensing?

Reduced Forecast Errors

By analyzing real-time causal factors, sensing can reduce short-term forecast errors by 20% to 50% (according to McKinsey & Company). Teams can identify "black swan" events, such as a product going viral on social media, allowing for stock adjustments within days rather than weeks. It also improves near-term forecast accuracy so you face fewer stockouts, overstocks, and markdowns strategies.

Lower Supply Chain Costs

Enhanced accuracy can reduce safety stock levels without risking service levels, which directly reduce your storage costs. Besides, more accurate predictions minimize the need for high-cost "emergency" measures like expedited air shipping or last-minute warehouse labor adjustments.

>> Read more: 16 Best Cost Reduction Strategies in Inventory Management

Increased Sales

Automated systems recommend or trigger inventory moves so the right products are allocated to the right channel/store at the right time. This directly improve on-shelf availability and customer loyalty because shelves are always stocked during peak periods and shoppers can get what they need without waiting too long.

During promotions, they also track live sales against the expected uplift in each region or channel and adjust the short-term forecast accordingly. This helps planners top up hot spots, reallocate stock from weaker areas, and avoid both empty shelves and wasted inventory.

Better Operational Decisions

AI-powered demand forecasting platforms automatically collect and process all the signals, so planners spend more time focusing on high-value tasks. These systems then deliver timely, data-driven alerts and recommendations, allowing teams to adjust plans proactively instead of reacting late.

Modern solutions also use Explainable AI (XAI) to show why a forecast changed (for example, “5% increase due to a local sporting event”), which builds trust between planners and the technology.

More Sustainable Operations

The fashion industry cause an estimated 2 million tonnes of textile waste, and one of its biggest causes is inaccurate forecasts. Demand sensing ensures that stock is not pushed to locations where it will sit idle, eventually requiring deep markdowns or ending up in landfills.

Demand sensing helps cut this waste by slowing or stopping production as soon as a trend cools and improving raw material management so that brands don’t commit to fabric and components they won’t use. It also makes sure inventory goes to stores and channels where it will actually sell, not sit idle and end up in landfills.

This reduction in garments overproduction and unsold stock lowers the carbon footprint of the supply chain. Brands also have stronger, data-backed evidence for their ESG (Environmental, Social, and Governance) reporting on waste, emissions, and responsible resource use.

>> You may need: Top 8 Best Raw Material Inventory Management Software

Benefits of Demand Sensing

How Does Demand Sensing Work?

Demand sensing is built on a structured, data-driven process. Here’s the full workflow:

1. Granular Data Collection (Signals)

Demand sensing collects high-frequency signals from multiple sources to identify current market trends::

Internal Data:

Sales orders;

Shipments;

Store/DC inventory;

Price changes;

Promotions;

Product master data.

Partner / Retailer Data:

POS sales;

Store inventory;

Supplier/retailer promotion calendars.

External Data:

Weather forecasts;

Local events;

Competitor price changes;

Social/online engagement signals;

Macro indicators.

Note: Signals must be fresh (daily or intraday) and granular (SKU × location × day). Modern demand sensing requires big data pipelines and cloud platforms to handle volume and velocity.

2. Data Processing

Once signals are collected, the system prepares vast, unorganized data for analysis through several refinement steps:

Clean and normalize hundreds of disparate data streams to ensure consistency across sources;

Remove anomalies, missing values, duplicate entries that can affect results;

Create engineered features (lag variables, weather impact, holiday flags);

Establish a baseline for true underlying demand by isolating noise from actual signals.

3. Data Modeling

Demand sensing uses non-linear machine learning models to capture complex, non-obvious patterns, such as:

Neural Networks: Effectively models sequential historical patterns and non-linear relationships.

Gradient Boosting Machines: Such as XGBoost, which are ideal for handling high-dimensional data with multiple external factors.

Ensemble Learning Methods: Combine multiple models to generate more reliable results.

The output is a probabilistic short-term forecast with confidence intervals for the next 0–8 weeks.

4. Data Reconciliation

The refined short-term forecast is integrated into broader business planning to ensure operational alignment:

Compare the AI-driven short-term “sense” against the long-term strategic S&OP forecast.

Automatically adjust inventory and replenishment rules to meet the sensed demand.

Feed updated demand into allocation, production, and procurement systems for immediate action.

>> You can consider: 10 Best Inventory Replenishment Software Solutions

5. Data Optimization

To build planner trust, advanced systems use:

Explainable AI (XAI): Explains why the forecast changed (e.g., “Weekend heatwave increased forecast by +18%”) to build planner trust.

Continuous Learning: Actual sales data is fed back into the model daily to retrain the algorithm and improve accuracy over time.

How Does Demand Sensing Work?

How to Implement Demand Sensing for Your Fashion Brand?

Successful adoption requires a structured rollout. Here’s a practical roadmap:

1. Define Scope & KPIs

Identify 3–5 high-value business outcomes to measure the success of the implementation:

Reduce stockouts by 20%: Improving on-shelf availability directly captures lost revenue.

Improve full-price sell-through by 10%: Better accuracy reduces the need for deep clearance markdowns.

Cut replenishment errors by 30%: Ensuring the right SKU is in the right location minimizes costly cross-region transfers.

Reduce aged inventory: Preventing overproduction limits the accumulation of dead stock that eventually ends up in landfills.

2. Audit Data Readiness

Demand sensing is only as effective as the data it consumes, requiring an audit of your current digital infrastructure:

Completeness of sales and inventory data: Ensure daily data flows are available for both physical and online channels.

Accessibility of external signals (POS, weather, competitor data): Verify the ability to ingest POS, weather, and competitor data via APIs or partner portals.

Data governance (cleaning rules, naming conventions): Establish strict cleaning rules and naming conventions to harmonize disparate data streams.

3. Select the Right Platform

Your demand sensing tool must include these four essential capabilities:

Ingest any internal/external data source (POS, ERP, PLM, Shopify, weather APIs).

Granular visibility at SKU × store/channel level.

Unified ML/AI engine across sensing, planning, replenishment, and pricing.

Native integration with downstream supply processes like replenishment, allocation, and production scheduling.

4. Pilot on a High-Value Product Line

To build planner buy-in and demonstrate ROI, launch a pilot program on a carefully selected category. Consider a category with::

High volatility: Choose products where demand shifts rapidly, making them difficult to forecast traditionally.

High revenue impact: Select a core category where improvements significantly affect the bottom line.

Frequent replenishment: Focus on items with short lead times where sensing can trigger immediate stock adjustments.

This delivers early wins and planner buy-in.

5. Integrate and Automate

Automation is key to reducing latency that is the time between sensing a shift and responding to it. Connect sensing signals directly to:

Replenishment logic: Automatically update target stock levels in stores based on daily sensed demand.

Production scheduling: Signal factories to adjust short-cycle manufacturing runs to match current sales trends.

Allocation engines: Re-route incoming shipments to locations with the highest predicted sell-through.

6. Continuous Performance Monitoring

Track metrics like:

Forecast Value Add (FVA): Measuring how much the sensing model improves accuracy over the traditional statistical baseline.

Stockouts and overstock rates: Monitoring the reduction in both lost sales and excess inventory.

Weeks of supply: Tracking improvements in inventory turnover.

Sell-through %: Confirming that more products are selling at full price as a result of better allocation.

Use results to refine models and improve ROI.

FAQs

1. What is the underlying demand sensing technology?

The core demand sensing technology are AI/ML models, especially neural networks and gradient boosting, that can process real-time signals to generate a short-term forecast. This tech stack requires big data pipelines and cloud-native platforms to handle volume and velocity of granular data.

2. How does demand sensing differ from demand planning?

Demand Planning focuses on the long-term and strategic (3–18 months), establishing baselines for budgeting and capacity planning.

Demand Sensing: Focuses on the short-term and reactive (0–8 weeks), adjusting forecasts daily or even intraday based on fresh market signals to improve immediate actions.

3. What are the three types of predictive models?

Machine learning models (e.g., XGBoost)

Deep learning models (e.g., LSTMs)

Hybrid ensemble models

4. Which tools support real-time demand sensing?

Leading solutions include:

AI-Driven Demand Sensing and Trend Forecasting: Nūl, Heuritech, Stylumia, EDITED, Nextail, Trendalytics, WGSN, Singuli, Syrup Tech, Designove

Enterprise Platforms: o9 Solutions, Blue Yonder, Antuit.ai, and ToolsGroup.

Native ERP Add-ons: Modules such as SAP IBP for Demand that integrate directly with core transactional data.

5. Who offers real-time demand sensing capabilities?

Next-generation planning and agentic AI platforms can offer real-time demand sensing capabilities. They can process intraday data, integrate external signals, and automatically update inventory decisions.

How Nūl Supports Demand Sensing?

Nūl’s agentic AI platform brings demand sensing directly into daily workflows for fashion operators:

Real-time multi-source data ingestion (Shopify, weather, social signals, returns, store stock).

AI-driven short-term forecasting at SKU × location × day granularity.

Explainable AI recommendations so teams understand why demand changed.

Native integration with replenishment, allocation, pricing, and materials planning, enabling rapid operational action.

Continuous learning loops that update models weekly or daily based on sell-through performance.

Nūl helps brands move from reactive planning to a proactive, predictive operating model.

Conclusion

Demand sensing is quickly becoming a competitive necessity in the fashion supply chain. With real-time data and AI-driven predictions, brands can reduce waste, increase full-price sell-through, prevent stockouts, and respond instantly to changing customer behaviour.

As trends accelerate and uncertainty becomes the norm, demand sensing gives brands the agility and intelligence needed to thrive.

Article by

Nūl Content Team

An Experienced Research & Knowledge Team

An Experienced Research & Knowledge Team

The Nūl Content Team combines expertise in technology, fashion, and supply chain management to deliver clear, practical insights. Guided by Nūl’s mission to end overproduction, we create content that helps brands forecast demand more accurately, optimize inventory, and build sustainable operations. Every piece we publish is grounded in real-world experience, ensuring it’s both credible and actionable.

LinkedIn Profile